Phosphate-modified waterborne epoxy ester resin and anti-corrosive primer thereof, and preparation methods of phosphate-modified waterborne epoxy ester resin and anti-corrosive primer

A technology of epoxy ester resin and epoxy resin, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of low hardness, slow drying of paint film, poor early water resistance, etc., to achieve increased crosslinking density, fast drying speed, good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

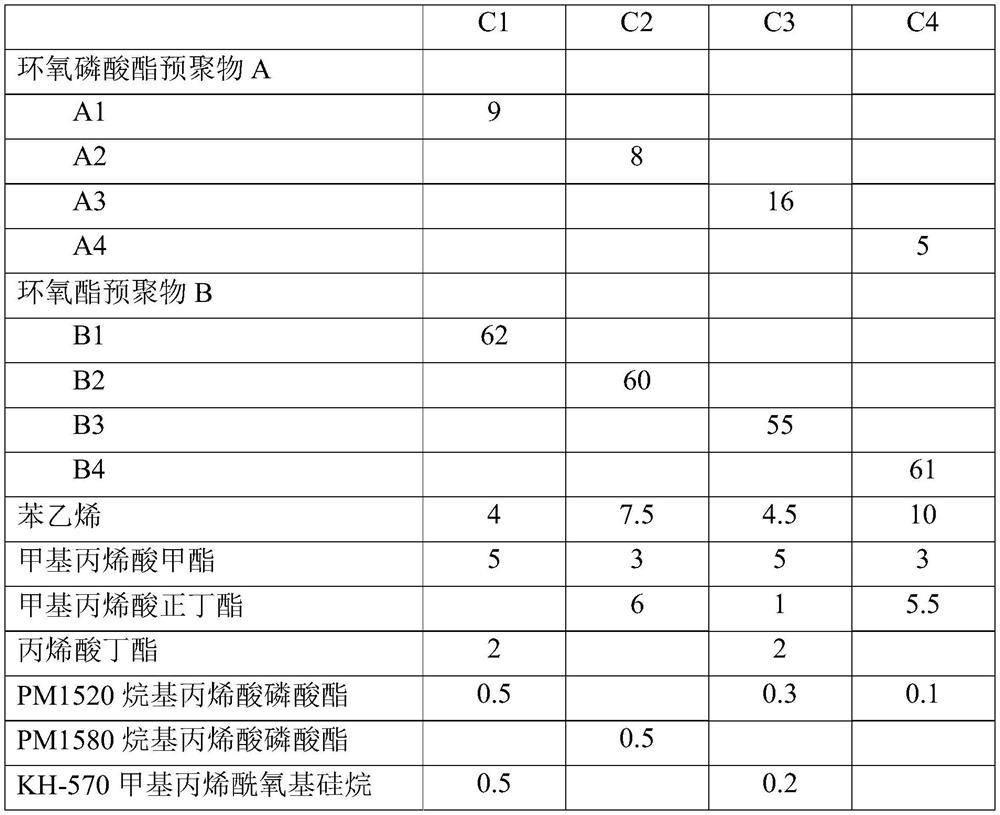

Examples

preparation example Construction

[0131] The preparation method of described waterborne epoxy ester antirust primer, comprises the steps:

[0132] (1) Add deionized water into the dispersion kettle and start stirring;

[0133] (2) While stirring, add neutralizer, wetting and dispersing agent and defoamer in sequence;

[0134] (3) under the condition of stirring, slowly add the water-based epoxy ester resin C modified by phosphoric acid ester to dilute it into a uniform emulsion;

[0135] (4) While stirring, slowly add pigments, anti-rust pigments and fillers, after stirring evenly, grind with a sand mill until the fineness is less than 30 microns, then transfer to the paint mixing kettle;

[0136] (5) While stirring, add water-based drier, leveling agent and thickener to the paint mixing kettle in sequence;

[0137] (6) Check the pH value and viscosity, adjust the pH value to 7.5 to 8.5, and the T-4 cup viscosity to be 60-100 seconds;

[0138] (7) filter with 120 mesh filter screens, pack, promptly obtain w...

Embodiment 1

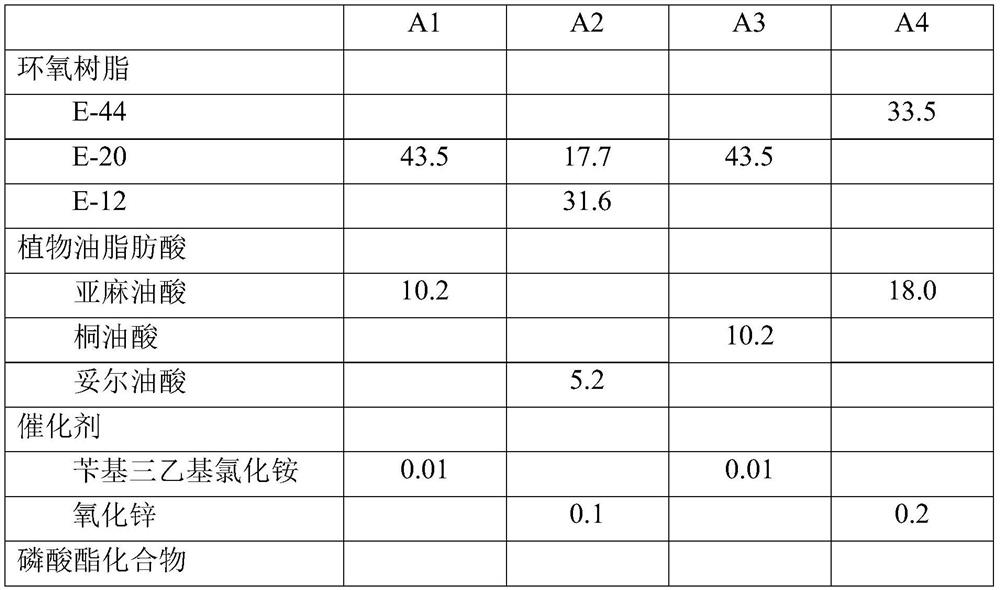

[0150] Preparation of Epoxy Phosphate Prepolymer A1~A4

[0151] Put the epoxy resin, vegetable oil fatty acid and catalyst into the reaction bottle, raise the temperature to 135°C, keep it warm for 2-3 hours, until the acid value is less than 5mgKOH / g; cool down to 95°C, mix the phosphate compound and the co-solvent evenly, Use a dropping funnel to add dropwise into the reaction bottle for reaction. Since it is an exothermic reaction, the drop rate should be controlled, and the dropwise addition is completed in 1.5 hours; Epoxy Phosphate Prepolymer A. The formulations of epoxy phosphate prepolymers A1-A4 are listed in Table 1.

[0152] Table 1 The formula of epoxy phosphate prepolymer A1~A4

[0153]

[0154]

Embodiment 2

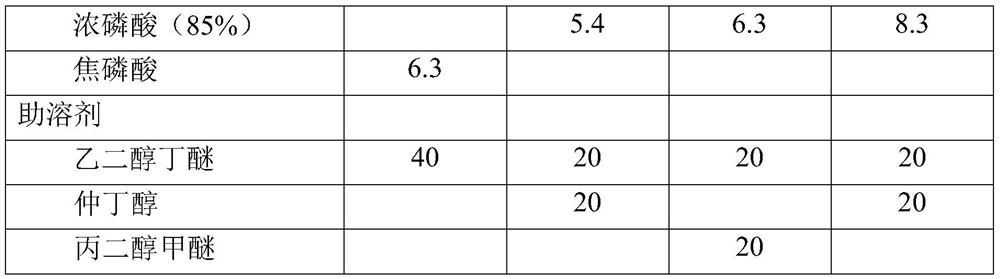

[0156] Preparation of Epoxy Ester Prepolymer B1~B4

[0157] Put the epoxy resin, vegetable oil fatty acid and catalyst into the reaction bottle, raise the temperature to 135°C, start stirring after the material melts; gradually raise the temperature to 225°C, and react at this temperature until the acid value is 10mgKOH / g, then start to cool down; cool down to Below 160°C, add co-solvent at 150°C to obtain epoxy ester prepolymer B. The formulations of epoxy ester prepolymers B1-B4 are listed in Table 2.

[0158] Table 2 The formula of epoxy ester prepolymer B1~B4

[0159] B1 B2 B3 B4 vegetable oil fatty acid Linoleic Acid 44.2 36 44.2 36 oleic acid 0.8 0.8 epoxy resin E-12 30 27 22.5 36 E-06 27 22.5 E-03 15 18 catalyst Benzyltriethylammonium chloride 0.036 0.036 Zinc oxide 0.04 0.036 Co-solvent Ethylene glycol butyl ether 30 15 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com