Wood fiber composite material squeezing molding equipment

A fiber composite material and extrusion molding technology, applied in the field of material molding, can solve the problems of brittle furniture surface patterns, difficulty in achieving consistent product density, cumbersome operation steps, etc., to achieve overall weight reduction, reduce manual operations, and parts little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

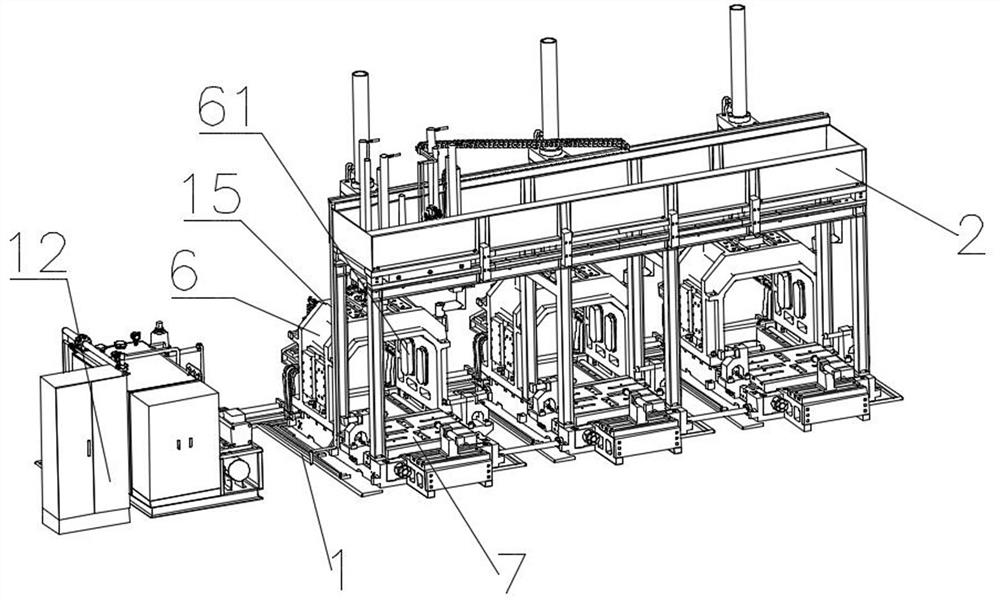

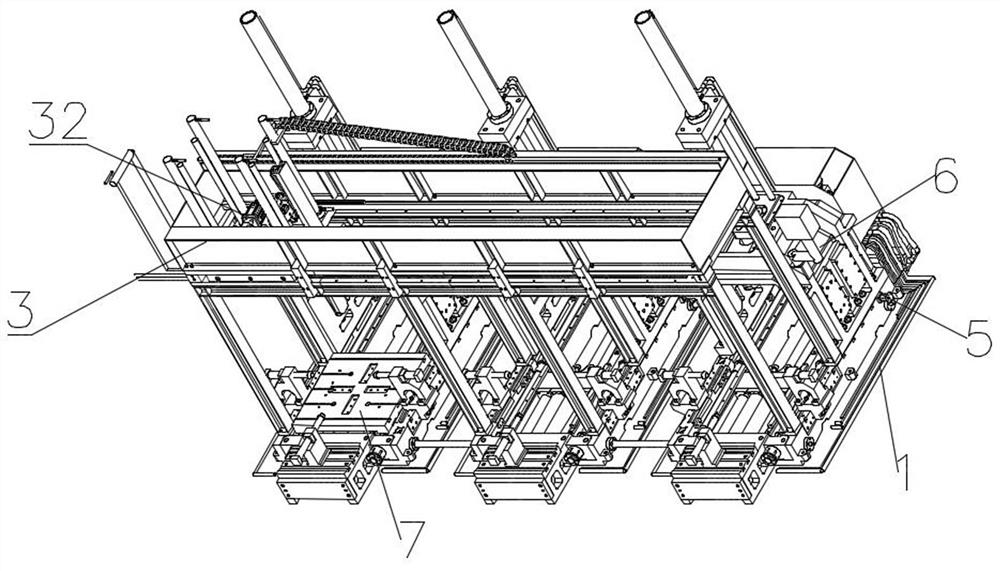

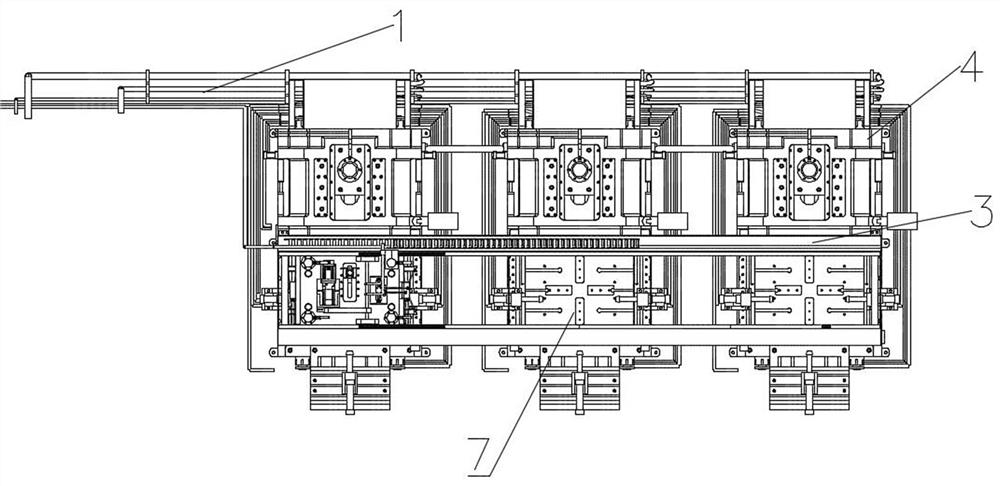

[0026] The following is attached Figure 1-7 The present invention is further described.

[0027] With the development of society, wood fiber composite materials gradually replace traditional furniture materials. Traditional furniture materials consume a lot, and environmental protection cannot meet the requirements, which is not conducive to sustainable development. Then wood fiber composite materials gradually enter the public's field of vision. The density of wood fiber composite materials is suitable , non-toxic and environmentally friendly, can be quickly degraded, the surface is dense and wear-resistant, and can be formed into complex shapes. No higher than other plant composite products, not only suitable for general household furniture industry, but also widely used in industrial production, but there is currently a lack of extrusion molding equipment suitable for this wood fiber composite material.

[0028] To this end, the present invention provides a wood fiber com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com