Preparation method of semiconductor high-purity titanium target material assembly

A titanium target and semiconductor technology, which is applied in the field of sputtering targets, can solve the problems of affecting the stability of the process and equipment, poor cooling effect, easy deformation, etc. The effect of using the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

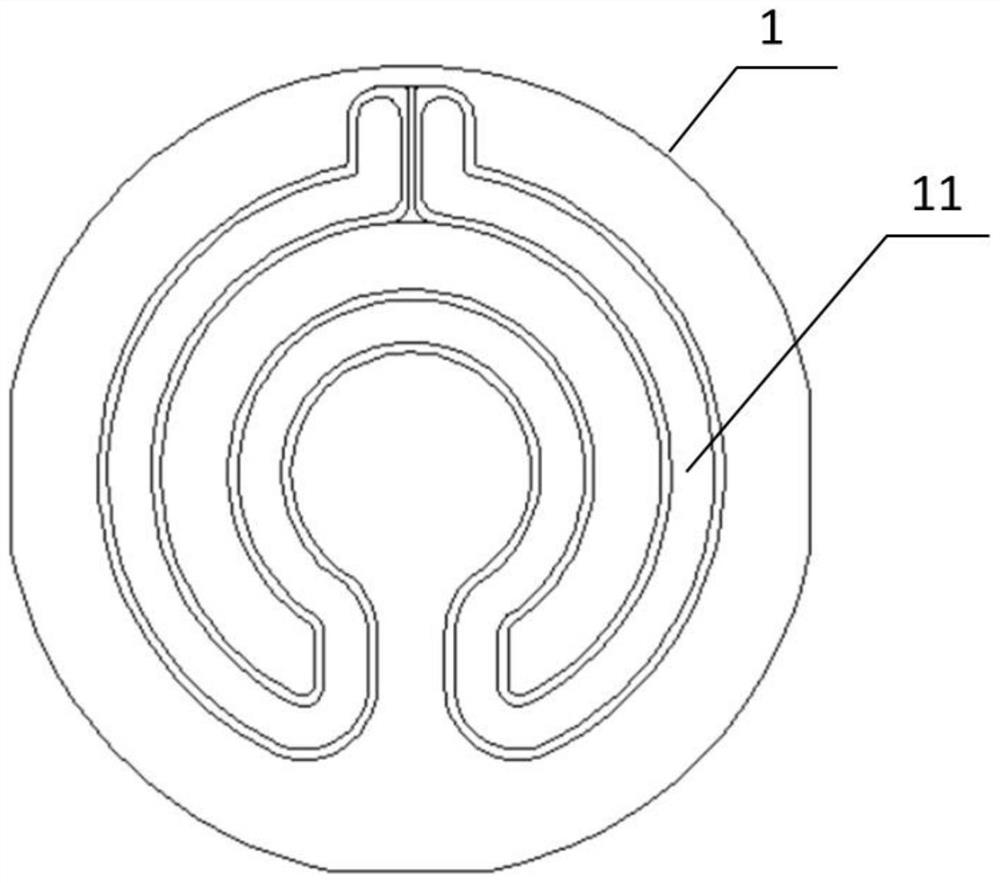

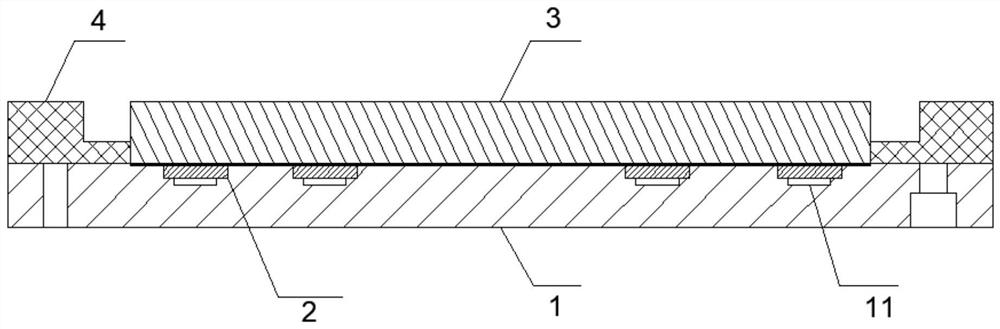

[0059] This embodiment provides a method for preparing a semiconductor high-purity titanium target assembly, the high-purity titanium target assembly includes a titanium target 3 and a back plate, the back plate includes a cover plate 2 and a substrate 1, and the substrate 1 is provided with a cooling water channel 11, and the structural schematic diagram of the substrate 1 is as follows figure 1 As shown, the preparation method comprises the following steps;

[0060] (1) The substrate 1 and the cover plate 2 are independently forged and stretched three times at 450°C, and then water-cooled once; after the first water-cooling, they are kept at 360°C for 100°C, and then rolled; Under the condition of keeping warm for 150min, then carry out secondary water cooling;

[0061] After the secondary water cooling, the base plate 1 and the cover plate 2 were polished independently. After polishing, the surface was first cleaned with acetone, and then ultrasonically cleaned with isopro...

Embodiment 2

[0067] This embodiment provides a method for preparing a semiconductor high-purity titanium target assembly, the high-purity titanium target assembly includes a titanium target 3 and a back plate, the back plate includes a cover plate 2 and a substrate 1, and the substrate 1 is provided with a cooling water channel 11, and the preparation method includes the following steps;

[0068] (1) The base plate 1 and the cover plate 2 are independently forged twice at 550°C, and then water-cooled once; after the first water cooling, they are kept at 320°C for 130 minutes, and then rolled; Under the condition of keeping warm for 170min, then carry out secondary water cooling;

[0069] After the secondary water cooling, the base plate 1 and the cover plate 2 were polished independently. After polishing, the surface was first cleaned with acetone, and then ultrasonically cleaned with isopropanol, and dried at 70°C after cleaning;

[0070] (2) Assemble the cover plate 2 and base plate 1 p...

Embodiment 3

[0074] This embodiment provides a method for preparing a semiconductor high-purity titanium target assembly, the high-purity titanium target assembly includes a titanium target 3 and a back plate, the back plate includes a cover plate 2 and a substrate 1, and the substrate 1 is provided with a cooling water channel 11, and the preparation method includes the following steps;

[0075] (1) The base plate 1 and the cover plate 2 are independently forged twice at 500°C, and then water-cooled once; after the first water cooling, they are kept at 330°C for 150 minutes, and then rolled; Insulated for 300min under certain conditions, and then subjected to secondary water cooling;

[0076] After the secondary water cooling, the base plate 1 and the cover plate 2 are polished independently. After polishing, the surface is firstly cleaned with acetone, and then ultrasonically cleaned with isopropanol, and dried at 50°C after cleaning;

[0077] (2) Assemble the cover plate 2 and base pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com