Preparation method of lithium-boron alloy strip blank

A lithium boron alloy and ingot billet technology is applied in the field of preparation of lithium boron alloy strip billets, which can solve the problems of low product yield, high material loss rate, damage to the structure of lithium boron compounds, etc., so as to improve the yield and ensure Stability, bright and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, these embodiments are provided to make the understanding of the disclosure of the present invention more thorough and comprehensive.

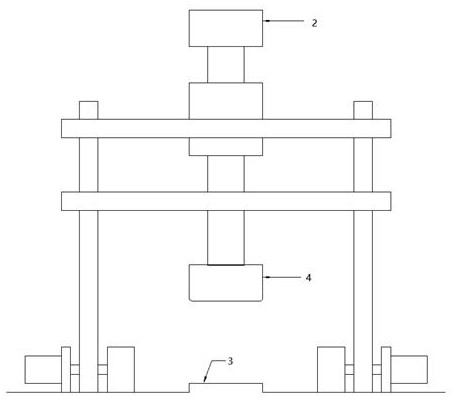

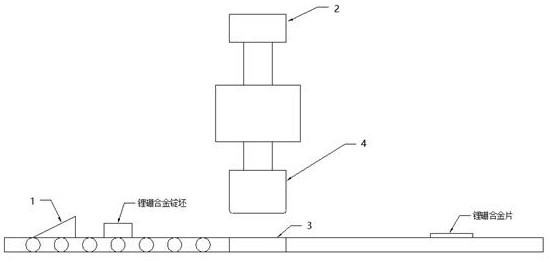

[0028] The invention provides a method for preparing a lithium-boron alloy strip blank. After removing the riser and cleaning the surface of a circular ingot, free pier pressing is performed to form a lithium-boron alloy square blank, and the lithium-boron alloy square blank is placed into the calender for thinning and one-way stretching, making it from a thick short billet to a thin billet suitable for finishing rolling into a strip. The calender includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com