Composition for preparing solid polymer electrolyte and application thereof

A composition and solid-state battery technology, applied in the field of lithium-ion batteries, can solve the problems of unsmooth ion transmission in the battery system, increase in interface impedance, and decrease in cycle performance, and achieve the effects of safety assurance, low viscosity, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

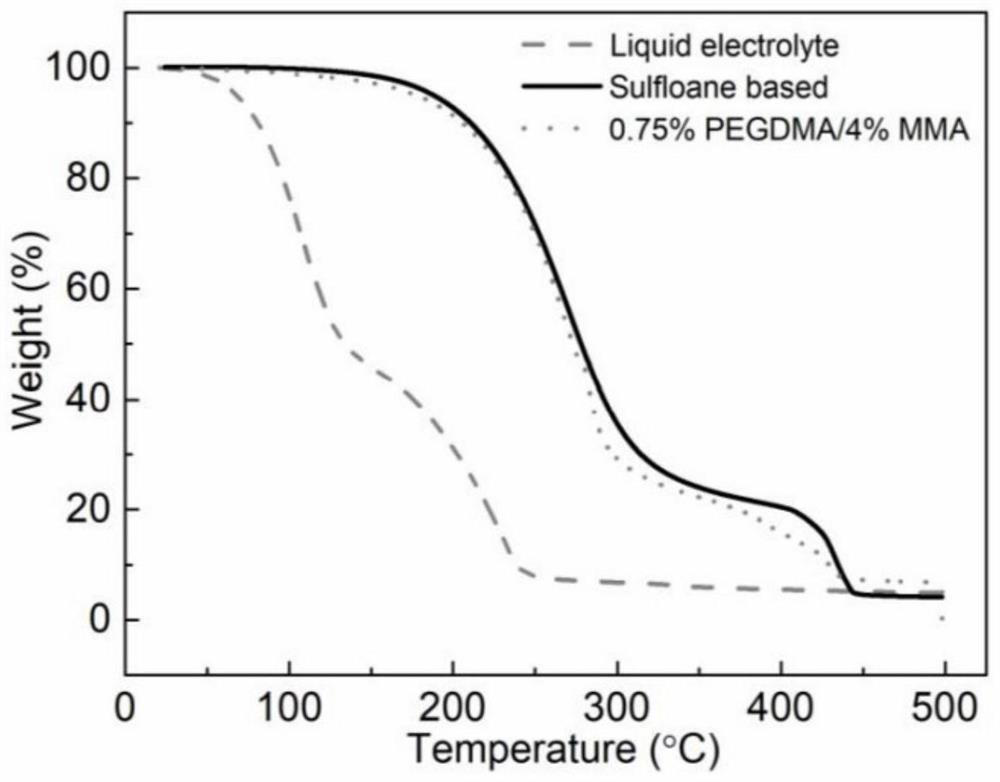

[0054] This embodiment provides a composition, including: LiTFSI, sulfolane, FEC, EC, PC, VC, PS, PST, AND, PEGDMA and AIBN;

[0055] Among them, in terms of mass ratio, sulfolane: FEC: EC: PC = 78: 10: 3: 9; based on the total mass of sulfolane, FEC, EC and PC, the concentration of LiTFSI is 1M, VC, PS, PST and AND The mass percentages are 0.5%, 3%, 0.7%, 0.6% respectively;

[0056] The mass percentage of PEGDMA in the composition is 5%; the mass percentage of AIBN in the composition is 0.2%.

[0057] This embodiment also provides a solid-state battery made using the above composition, specifically as follows:

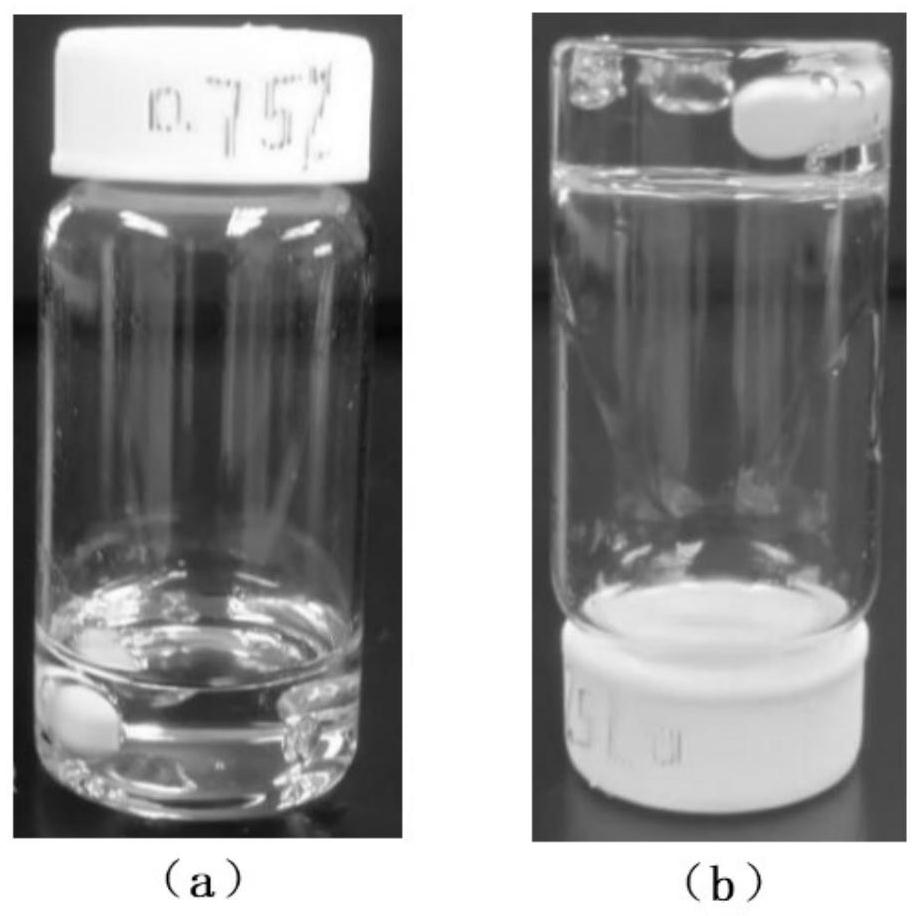

[0058] (1) After mixing LiTFSI, sulfolane, FEC, EC, PC, VC, PS, PST, AND according to the above ratio, a non-flammable electrolyte was obtained;

[0059] Among them, sulfolane, FEC, EC, PC, VC, PS, PST and AND all adopt the Molecular sieves are used for water removal treatment to eliminate the influence of water on battery performance;

[0060] (2) Add PEGDMA and...

Embodiment 2

[0067] This embodiment provides a composition, including: LiTFSI, sulfolane, FEC, EC, PC, VC, PS, PST, AND, PEGDMA, MMA and AIBN;

[0068] Wherein, in terms of mass ratio, sulfolane:FEC:EC:PC=78:10:3:9; based on the total mass of sulfolane, FEC, EC and PC, the concentration of LiTFSI is 1M.

[0069] The mass percentage of PEGDMA in the composition is 1%; the mass percentage of MMA in the composition is 4%; the mass percentage of AIBN in the composition is 0.2%.

[0070] This embodiment also provides a solid-state battery made using the above composition, specifically as follows:

[0071] (1) After mixing LiTFSI, sulfolane, FEC, EC, PC, VC, PS, PST, AND according to the above ratio, a non-flammable electrolyte was obtained;

[0072] Among them, sulfolane, FEC, EC, PC, VC, PS, PST and AND all adopt the Molecular sieves are used for water removal treatment to eliminate the influence of water on battery performance;

[0073] (2) Add PEGDMA, MMA and AIBN to 5.0 g of non-flammab...

Embodiment 3

[0077] This embodiment provides a composition, including: LiTFSI, sulfolane, FEC, EC, PC, VC, PS, PST, ADN, PEGDMA, MMA and AIBN;

[0078] Wherein, in terms of mass ratio, sulfolane:FEC:EC:PC=78:10:3:9; based on the total mass of sulfolane, FEC, EC and PC, the concentration of LiTFSI is 1M.

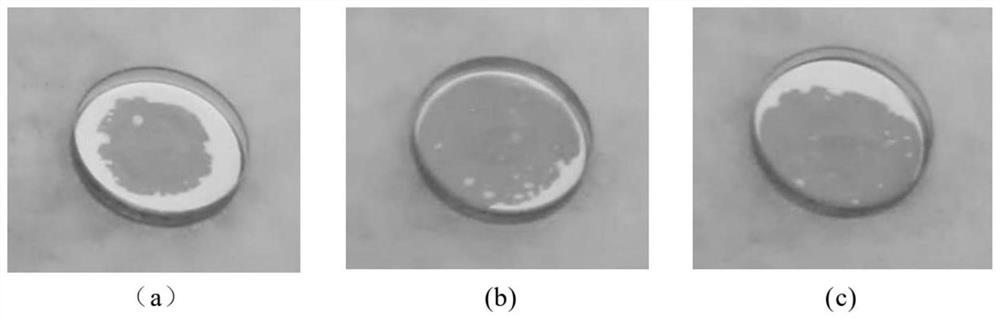

[0079] The mass percentage of PEGDMA in the composition is 0.75%; the mass percentage of MMA in the composition is 4%; the mass percentage of AIBN in the composition is 0.2%.

[0080] This embodiment also provides a solid-state battery made using the above composition, specifically as follows:

[0081] (1) After mixing LiTFSI, sulfolane, FEC, EC, PC, VC, PS, PST, and ADN according to the above ratio, a non-flammable electrolyte was obtained;

[0082] Among them, sulfolane, FEC, EC, PC, VC, PS, PST and ADN have all adopted the Molecular sieves are used for water removal treatment to eliminate the influence of water on battery performance;

[0083] (2) Add PEGDMA, MMA and AIBN to 5.0 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com