Parameter adjusting method of high-speed switch valve

A high-speed on-off valve, parameter adjustment technology, applied in electrical digital data processing, control valve and air release valve, special data processing applications, etc. Rapidity, increasing the range of effective duty cycle, optimizing parameter selection and the effect of the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

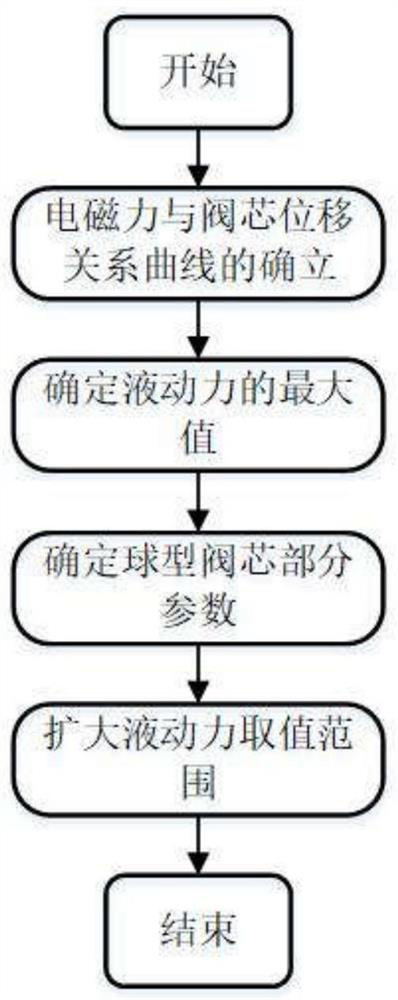

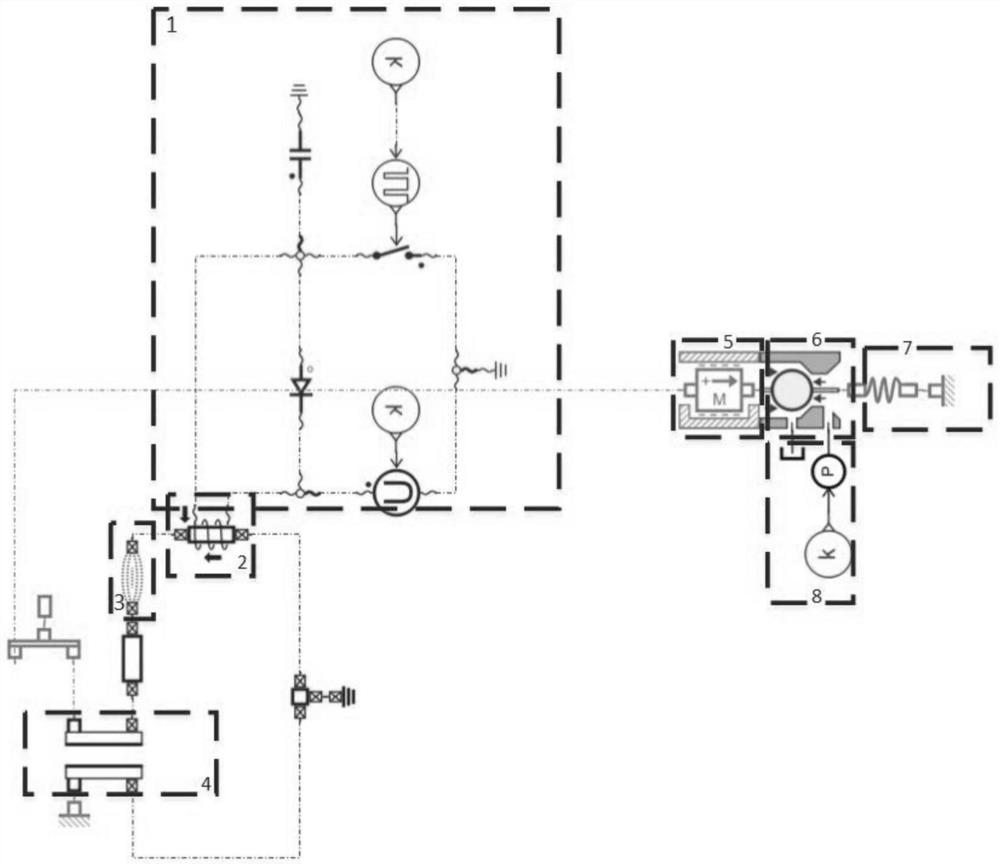

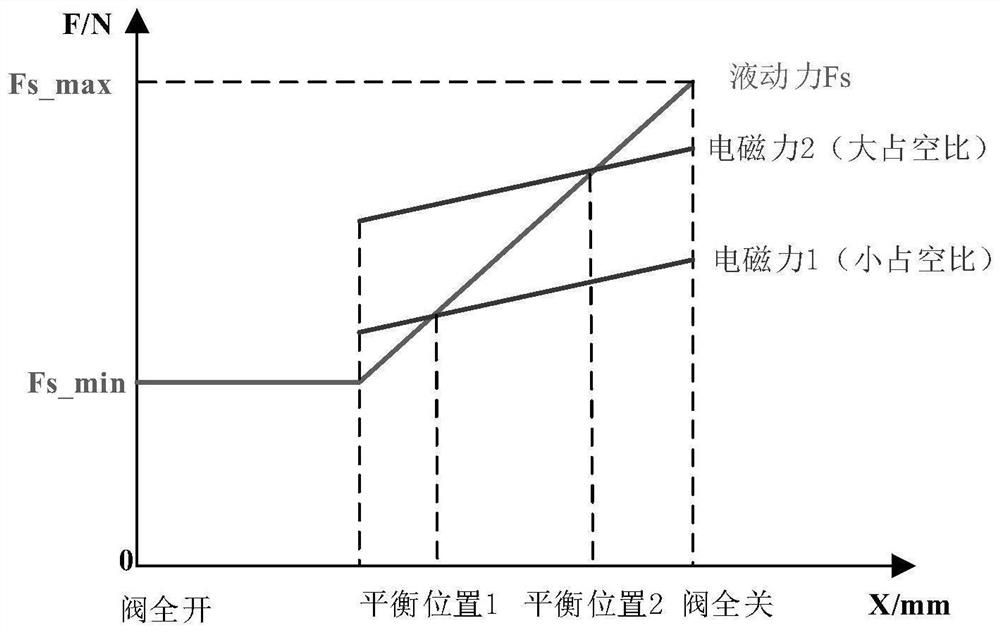

[0041] The invention discloses a parameter adjustment method of a high-speed switching valve, analyzes the internal composition and force analysis of the high-speed switching valve, fully considers the influence of electromagnetic force and hydraulic force, and at the same time, according to the formula satisfied by the high-speed switching valve, fully The influence of electromagnetic correlation coefficients such as PWM wave duty cycle, PWM wave frequency, and number of coil turns, and valve core correlation coefficients such as valve seat semi-cone angle, pressure difference, and ball diameter on valve core displacement are considered. The basic principle of this method is based on the fact that the position of the spool is determined by the intersection point of the electromagnetic force and the hydraulic power curve, so the position of the intersection point can be control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com