A kind of high-efficiency gas suspension proppant for fracturing and preparation method thereof

A proppant and air suspension technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve the problems of small number of bubble adsorption, discount of air suspension effect, weak bubble adsorption, etc., to achieve enhanced Aerophilicity, increased roughness, and improved adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] This application document discloses a preparation method of a high-efficiency gas suspension proppant for fracturing, including:

[0034] Provide proppant particles, surface modification treatment solution, modifier solution, organic molecular linking agent;

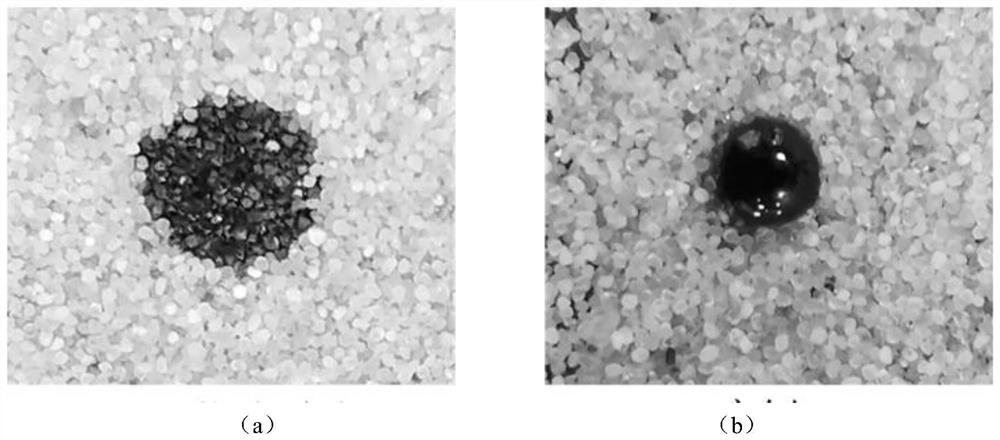

[0035] Using the surface modification treatment solution to agitate the proppant particles at a temperature of 25-120° C. to perform surface roughening treatment, separation, and drying to obtain surface-roughened proppant particles;

[0036] Mixing the surface-roughened proppant particles with the modifier solution and the organic molecular linking agent, performing a modification reaction, separating and drying to obtain a modified proppant;

[0037] Wherein, the surface modification treatment solution is selected from any one of silicate solution, inorganic nanoparticle buffer solution, and the modifier; the modifier is selected from aminopropyltriethoxysilane , hexadecyltrimethoxysilane, methyltriethoxysilane...

Embodiment 1

[0060] (1) Dissolve 1.3 parts by weight of tridecanoic acid and 4 parts by weight of hexadecyltrichlorosilane in 50 parts by weight of ethanol respectively, and heat the solution to 50° C.; obtain the ethanol solution of tridecanoic acid and The ethanolic solution of hexadecyltrichlorosilane, and the ethanolic solution of hexadecyltrichlorosilane is divided into A solution and B solution for use.

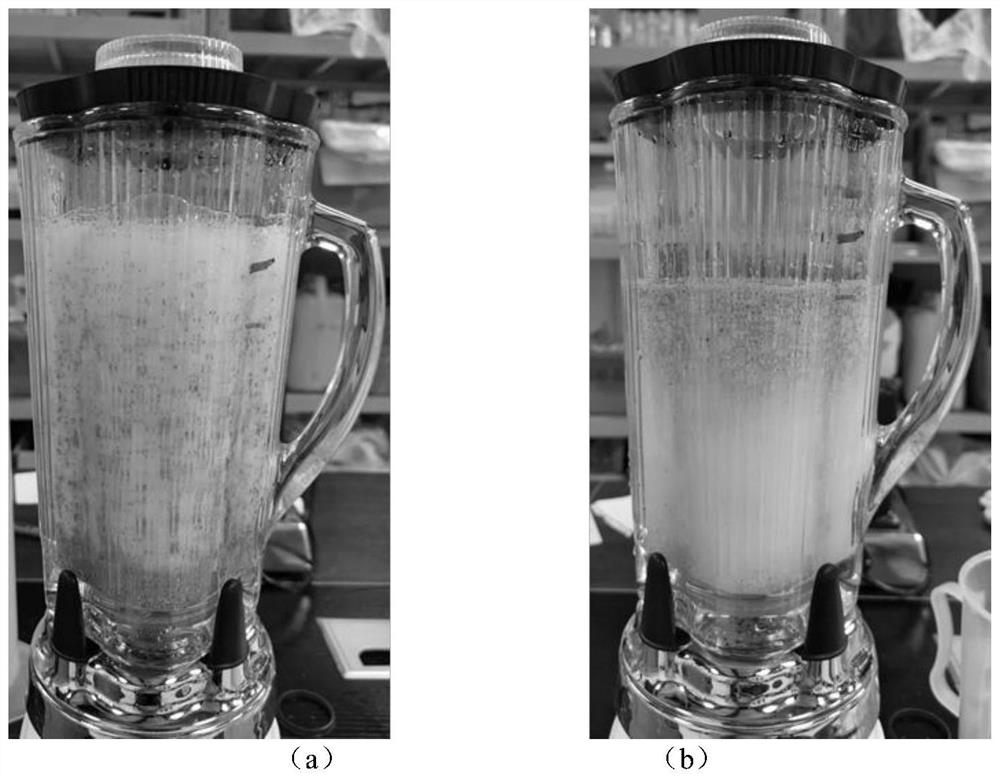

[0061] (2) Add 100 parts by weight of ultrasonically cleaned 20-40 mesh ceramsite into the A solution, stir quickly for 3 minutes to be uniform, and let stand for 2 hours at room temperature after the stirring is stopped.

[0062] (3) filtering to obtain the modified ceramsite filter material, and drying it in an oven at a temperature of 80° C. to obtain the ceramsite with surface roughening treatment;

[0063] (4) Mixing 1.3 parts by weight of tridecanoic acid and B solution to obtain a modifier solution, adding the surface-roughened ceramsite to the modifier solution, stirring for...

Embodiment 2

[0065] (1) Prepare a total of 500 parts by weight of ethanol / water solution with a volume ratio of 1:2, add 0.1 wt% cationic surfactant cetyltrimethylammonium bromide (CTAB) to it to dissolve, and then dissolve sodium metasilicate Dissolving in the ethanol / aqueous solution at a concentration of 4 wt %, rapidly and continuously stirring for 1 h at normal temperature, an aqueous solution of nano-silica is prepared.

[0066] (2) Evenly spray the nano-silica aqueous solution on the surface of 5,000 parts by weight of 20-40 mesh ceramsite, and conduct sufficient stirring to make the nano-silica adhere to the surface to form a rough structure, and then at 120 ° C drying for 2 h to obtain SiO 2 Modified ceramsite.

[0067] (3) Dissolving cetyltrimethoxysilane with ethanol to prepare an ethanol solution with a content of 15wt%, and then spraying the cetyltrimethoxysilane ethanol solution on SiO at a concentration of 0.6wt% 2 Modified ceramsite was obtained after stirring for 1.5 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com