Low-frequency wave-absorbing iron-based magnetic foam wave-absorbing material and preparation method thereof

A technology of magnetic foam and wave absorbing material, applied in the field of wave absorbing material, can solve the problems of affecting the effect of wave absorbing material, uneven material distribution, poor high temperature characteristics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

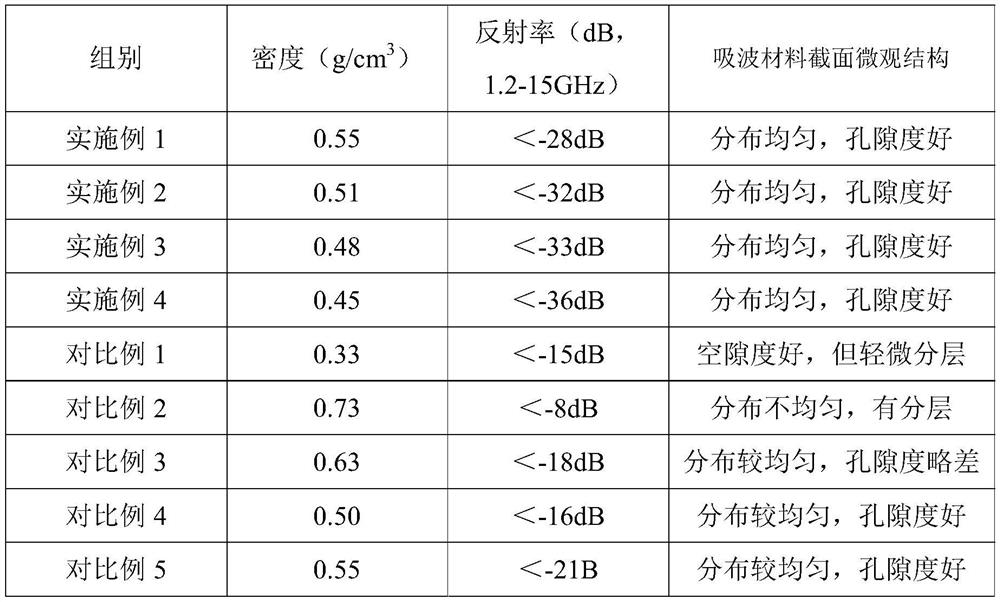

Examples

Embodiment 1

[0031] An iron-based magnetic foam absorbing material for low-frequency wave absorption, in parts by weight, the iron-based magnetic foam absorbing material includes the following raw material components: 50 parts of carbonyl iron powder; 15 parts of resin; 10 parts of silicon airgel fat 10 parts of alcohol polyoxyethylene ether; 80 parts of ethanol; wherein, the resin is a mixture of polyurethane resin and epoxy resin with a mass ratio of 2:1.

[0032] Its preparation method specifically comprises the following steps:

[0033] S1. Weigh each raw material according to the proportion, and set aside;

[0034] S2. dissolving the resin in an organic solvent, and fully stirring to obtain a resin liquid;

[0035] S3. Add the iron-based magnetic powder and dispersant to the resin solution of S2, stir evenly, and then continue to mix with ultrasonic waves for 2 hours to obtain the rubber compound;

[0036] S4. Add half of the airgel to the rubber compound of S3, using an air volume ...

Embodiment 2

[0040] An iron-based magnetic foam absorbing material for low-frequency absorbing, in parts by weight, the iron-based magnetic foam absorbing material includes the following raw material components: 50 parts of carbonyl iron powder; 15 parts of resin; 10 parts of silicon airgel; 10 parts of fatty alcohol polyoxyethylene ether; 80 parts of ethanol; wherein, the resin is a mixture of polyurethane resin and epoxy resin with a mass ratio of 2:1.

[0041] Its preparation method specifically comprises the following steps:

[0042] S1. Weigh each raw material according to the proportion, and set aside;

[0043] S2. dissolving the resin in an organic solvent, and fully stirring to obtain a resin liquid;

[0044] S3. Add the iron-based magnetic powder into the acid solution and soak for 1 hour, stir 3 times during the period, then rinse 3 times with water, dry it and add it to the resin solution of S2, add a dispersant at the same time, stir evenly, and then use ultrasonic waves to cont...

Embodiment 3

[0049] An iron-based magnetic foam absorbing material for low-frequency wave absorption, in parts by weight, the iron-based magnetic foam absorbing material includes the following raw material components: 55 parts of iron-manganese alloy powder; 15 parts of resin; 15 parts of carbon airgel 12 parts of sodium dodecylbenzenesulfonate; 100 parts of acetone; wherein, the resin is a mixture of polyurethane resin and epoxy resin with a mass ratio of 2.5:1.

[0050] Its preparation method specifically comprises the following steps:

[0051] S1. Weigh each raw material according to the proportion, and set aside;

[0052] S2. dissolving the resin in an organic solvent, and fully stirring to obtain a resin liquid;

[0053] S3. Add the iron-based magnetic powder into the acid solution and soak for 1 hour, stir 3 times during the period, then rinse with water 2 times, dry and add to the resin solution of S2, add dispersant at the same time, stir evenly, and then continue to mix with ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com