Humic acid fertilizer for preventing soil hardening and preparation method thereof

A soil compaction and humic acid technology, which is applied to nitrate fertilizers, ammonium orthophosphate fertilizers, and alkaline orthophosphate fertilizers, can solve problems such as fertilizer supply, fertilizer retention, weak water retention capacity, energy consumption, and impact on absorption. Achieve the effect of improving cation exchange capacity, improving absorption capacity and preventing soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

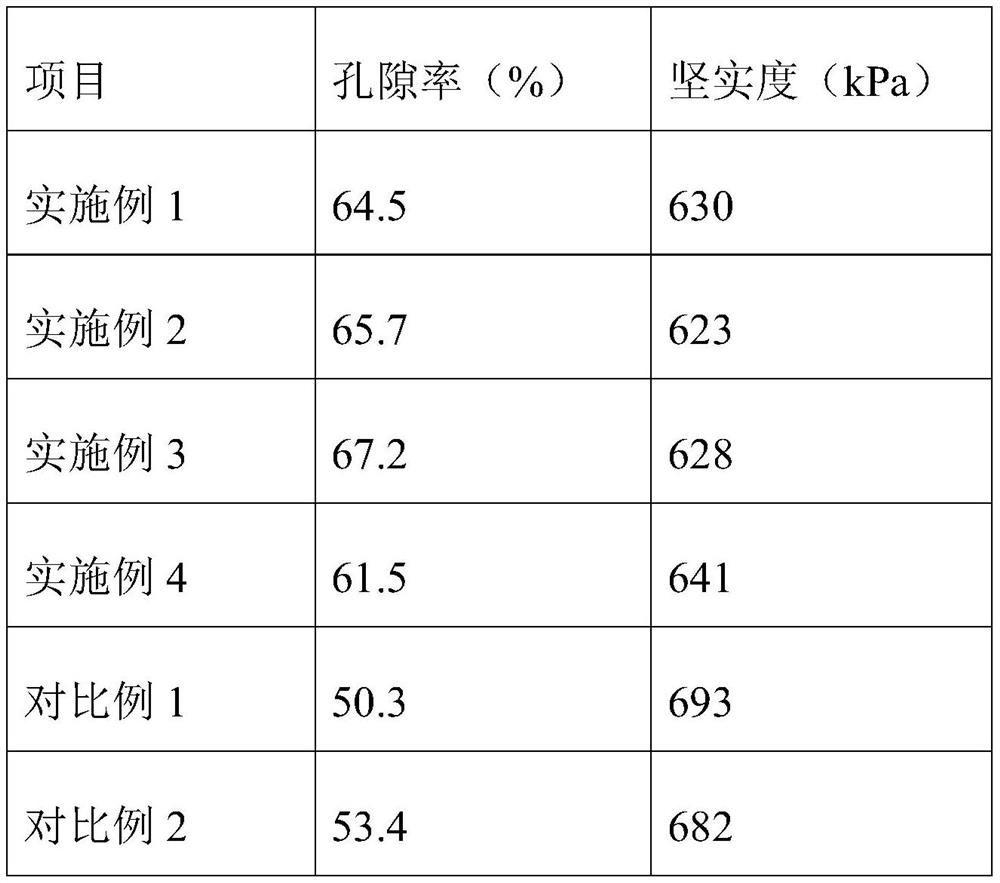

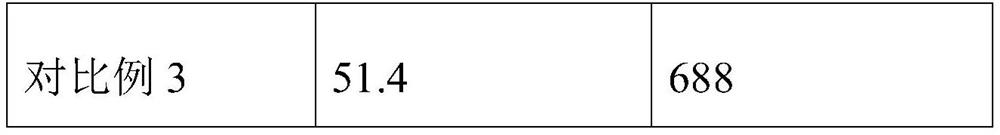

Examples

Embodiment 1

[0036] A humic acid fertilizer for preventing soil compaction, comprising the following components in parts by mass:

[0037] 50 parts of urea, 30 parts of potassium nitrate, 10 parts of monoammonium phosphate, 10 parts of potassium sulfate, 1 part of polyaspartic acid, 1 part of magnesium oxide, 1 part of calcium carbonate, 5 parts of humic acid, 3 parts of nano diatomite, 5 parts of silicon dioxide; 1 part of trace elements, said trace elements include boron, zinc, iron, manganese, molybdenum and magnesium, and the particle size ratio of the nano diatomite to silicon dioxide is 1:3.

[0038] The surface of the humic acid fertilizer is coated with a coating, and the coating includes the following components in parts by mass: 20 parts of humic acid, 3 parts of starch, 5 parts of talcum powder, 5 parts of chitosan, and 1 part of polyacrylamide , 1 part of citric acid; 30 parts of microbial inoculum, the microbial inoculum includes bacillus and lactobacillus, and the effective n...

Embodiment 2

[0048] A humic acid fertilizer for preventing soil compaction, comprising the following components in parts by mass:

[0049] 70 parts of urea, 40 parts of potassium nitrate, 30 parts of monoammonium phosphate, 30 parts of potassium sulfate, 5 parts of polyaspartic acid, 5 parts of magnesium oxide, 5 parts of calcium carbonate, 15 parts of humic acid, 10 parts of nano diatomite, 15 parts of silicon dioxide; 5 parts of trace elements including boron, zinc, iron, manganese, molybdenum and magnesium; the particle diameter ratio of the nano diatomite and silicon dioxide is 1-5.

[0050] The surface of the humic acid fertilizer is coated with a coating, and the coating includes the following components in parts by mass: 30 parts of humic acid, 8 parts of starch, 9 parts of talcum powder, 10 parts of chitosan, and 3 parts of polyacrylamide , 5 parts of EDTA; 50 parts of microbial inoculum, said microbial inoculum includes Pseudomonas, Bacillus, Lactobacillus, and the number of effec...

Embodiment 3

[0060] A humic acid fertilizer for preventing soil compaction, comprising the following components in parts by mass:

[0061] 60 parts of urea, 35 parts of potassium nitrate, 20 parts of monoammonium phosphate, 20 parts of potassium sulfate, 3 parts of polyaspartic acid, 3 parts of magnesium oxide, 3 parts of calcium carbonate, 10 parts of humic acid, 6 parts of nano diatomite, 10 parts of silicon dioxide; 2 parts of trace elements, the trace elements include boron, zinc, iron, manganese, molybdenum and magnesium, and the particle diameter ratio of the nanometer diatomite to silicon dioxide is 1:4.

[0062] The surface of the humic acid fertilizer is coated with a coating, and the coating includes the following components in parts by mass: 20 parts of humic acid, 3 parts of starch, 5 parts of talcum powder, 5 parts of chitosan, and 1 part of polyacrylamide , 1 part of citric acid; 30 parts of microbial inoculum, the microbial inoculum includes bacillus and lactobacillus, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com