Weldability test method for evaluating toughness of welding heat affected zone of medium-thickness plate

A technology of welding heat-affected zone and test method, which is applied in the direction of welding/welding/cutting items, welding equipment, welding accessories, etc., can solve the problems of poor accuracy, achieve high accuracy, save man-hours, and reduce the amount of welding wire filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A weldability test method for evaluating the toughness of the heat-affected zone of medium-thick plate welding, comprising the following steps:

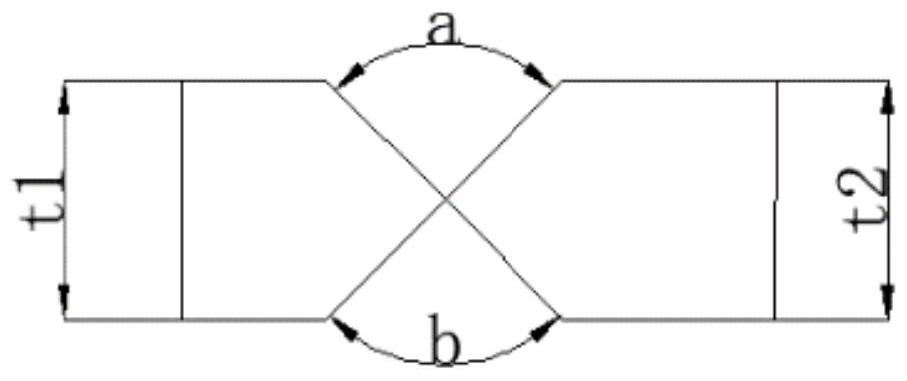

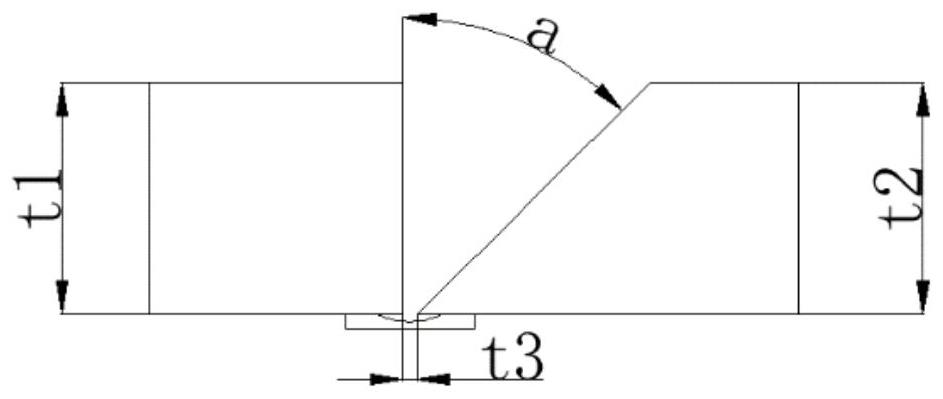

[0033] Prepare two test steel plates of the same size to be evaluated, the thickness t1 of steel plate 1 is 50mm, the thickness t2 of steel plate 2 is 50mm, and the steel type is Q690D; adopt 82% Ar+18% CO 2 Gas shielding, solid core wire with a diameter of Ф1.2mm; the first steel plate does not process the groove, and the second steel plate processes the V-shaped groove, and the assembly form is as follows figure 2 As shown, the assembly gap t3 is 0-2mm, the steel plate liner is assembled on the back, the groove is filled by multi-layer multi-pass welding, and the welding is automated with large-scale heat input, and the back does not need to be cleaned and repaired.

[0034] 1. Preparation before welding

[0035] according to figure 2 Cut the test plate according to the pattern. The steel plate 1 does not process the gro...

Embodiment 2

[0042] A weldability test method for evaluating the toughness of the heat-affected zone of medium-thick plate welding, comprising the following steps:

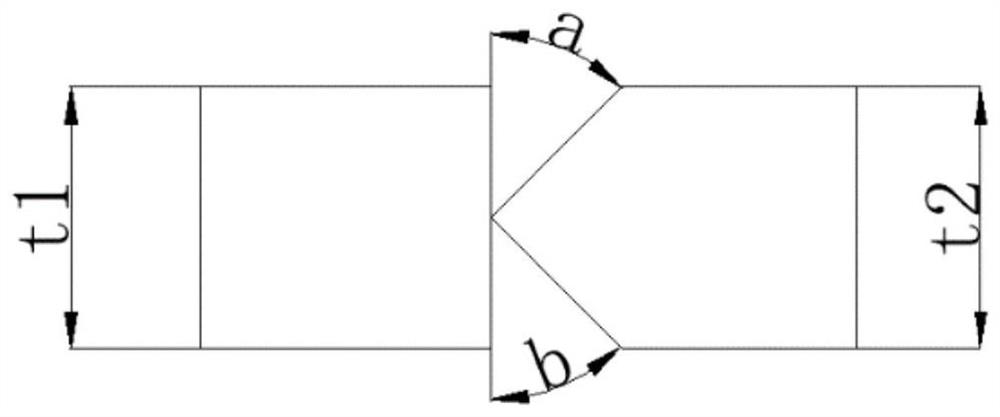

[0043] Prepare two test steel plates of the same size to be evaluated, the thickness t1 of steel plate 1 is 80mm, the thickness t2 of steel plate 2 is 80mm, and the steel type is Q550D; use 82% Ar+18% CO 2 Gas shielding, solid core wire with a diameter of Ф1.2mm; steel plate 1 does not process grooves, and steel plate 2 processes K-shaped grooves. The assembly form is as attached image 3 As shown, the assembly gap t3 is 0 ~ 2mm, and the steel plate liner is assembled on the back, using multi-layer multi-pass welding, automatic large-scale energy welding, and there is no need for root cleaning and repair welding on the back.

[0044] 1. Preparation before welding

[0045] according to image 3Cut the test plate according to the pattern. The first steel plate does not process the groove, and the second steel plate processes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com