Preparation device and preparation method for powder photocatalytic material

A technology for photocatalytic materials and preparation devices, which is applied in chemical instruments and methods, solid separation, sieving, etc., can solve the problems of powder photocatalytic materials not being able to be produced continuously, affecting production efficiency, etc., so as to achieve practical and enhanced devices. Practicality, the effect of enhancing the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

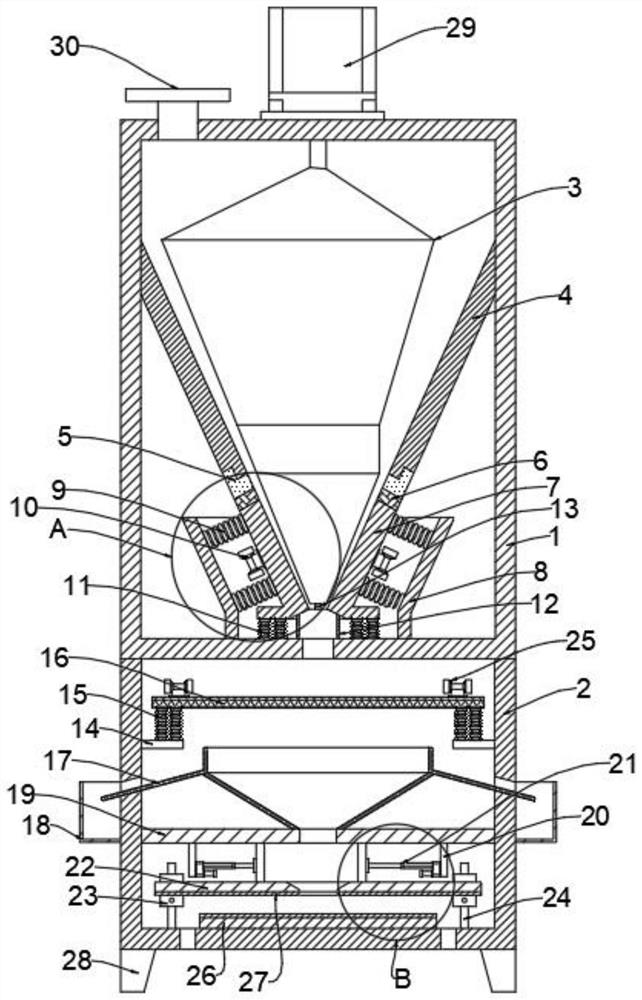

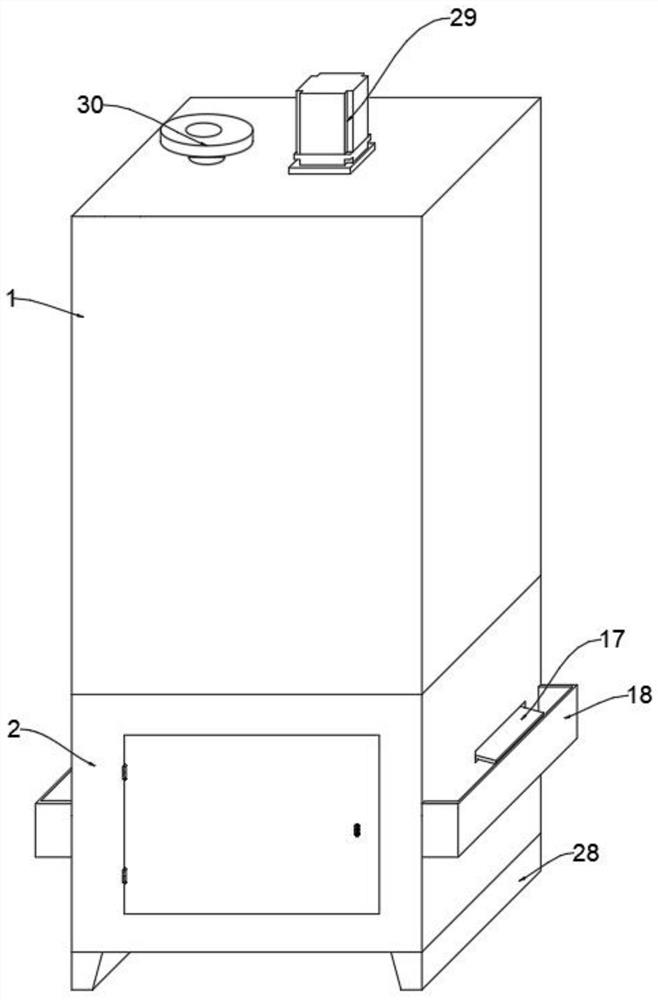

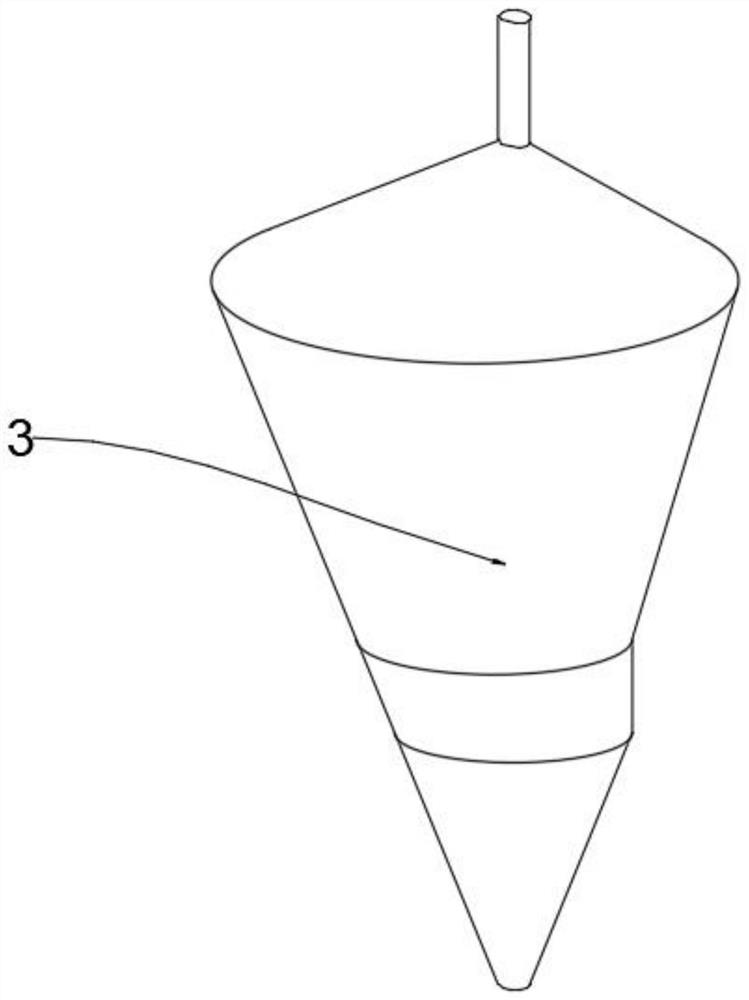

[0026] see Figure 1-5 , an embodiment provided by the present invention: a preparation device for powder photocatalytic materials, including an upper bracket 1, an abrasive piece 3 is installed inside the upper bracket 1, and the abrasive piece 3 is installed and arranged in an eccentric structure , so that the device can quickly grind the material to prevent the phenomenon of material jamming, and at the same time, the refined material can gradually move down, so that the device can grind and refine the material while feeding, without stopping the device, so that the material can be carried out continuously For refinement, there is no need to produce a batch of mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com