Normal-temperature high-calcium oat-based beverage and preparation method thereof

An oatmeal and high-calcium technology, applied in the field of food and beverage processing, can solve the problems of unnatural taste of products, bad taste of calcium chloride, precipitation of feed liquid, etc., to improve solubility and stability, and improve product taste and stability , the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

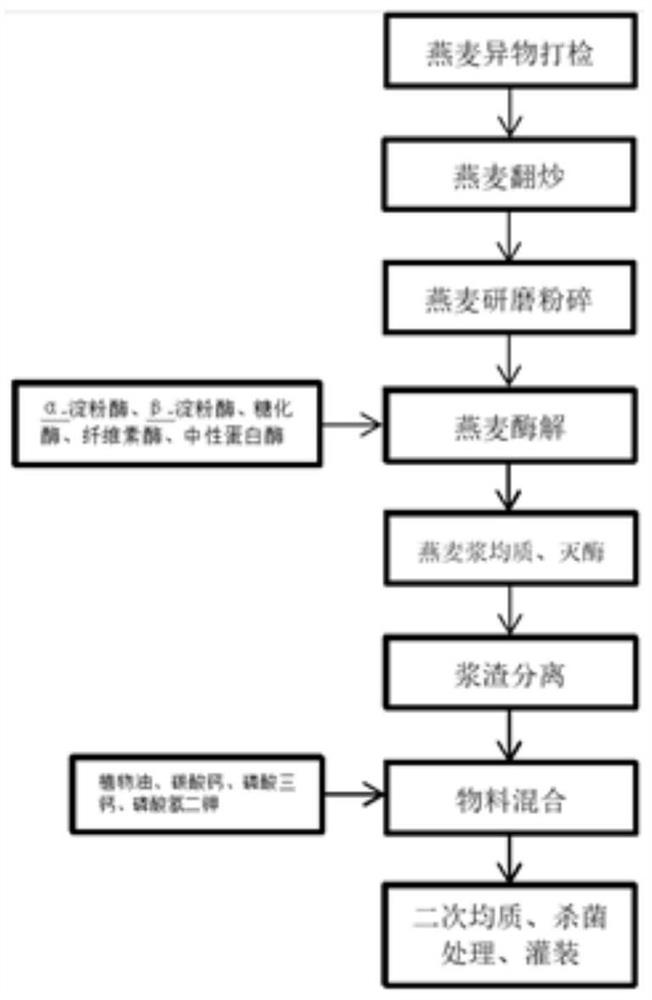

Method used

Image

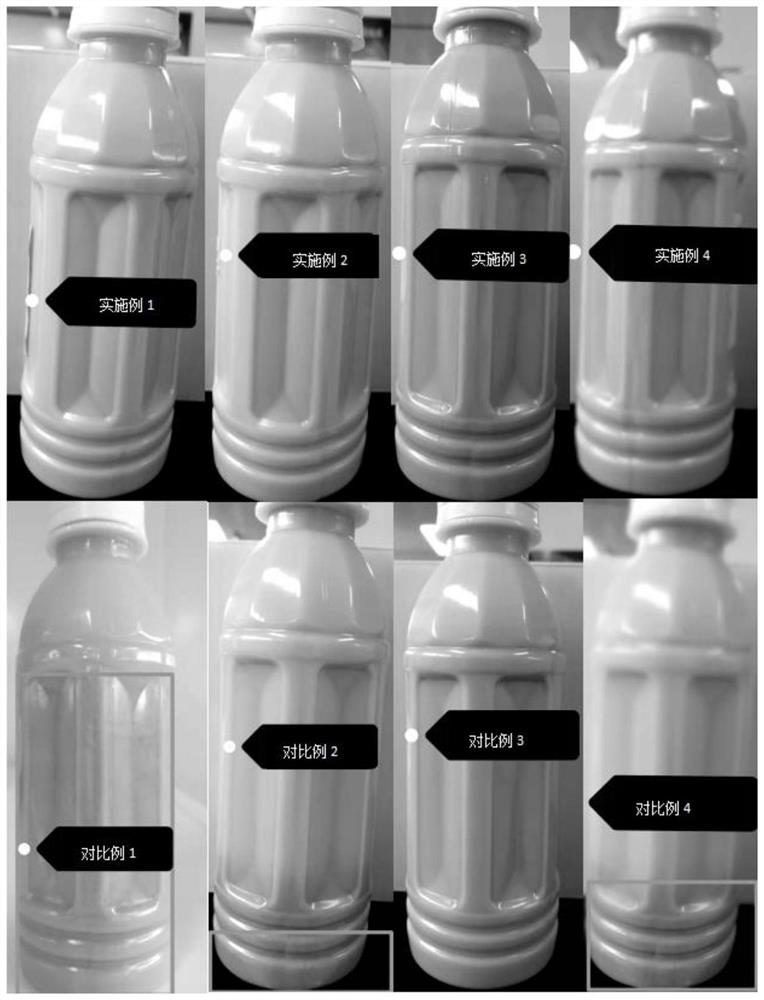

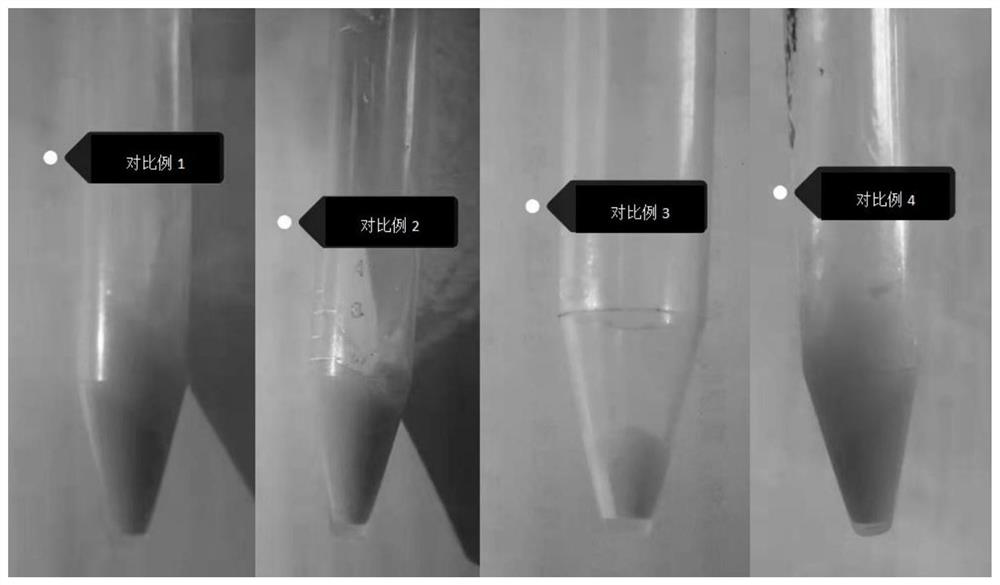

Examples

Embodiment 1

[0062] Oat 11%, vegetable oil 2%, enzyme preparation (α-amylase 0.015%, β-amylase 0.0005%, neutral protease 0.001%, glucoamylase 0.015%, cellulase 0.0008%), calcium carbonate 0.2%, triphosphate Calcium 0.1%, dipotassium hydrogen phosphate 0.05%, and the balance is water.

[0063] Sorting stones, metals, wheat husks and other foreign objects in the oats, frying the sorted oats in an oven at 250°C for 60 minutes, then cooling to 25°C, adding the stir-fried oats to a pulverizer for grinding Make powder, control the temperature of hot water at 60°C, add enzyme preparation and obtained oat flour in sequence, start stirring, keep warm for 1.0h, obtain oat pulp base material, homogenize the oat pulp base material, homogenization pressure: 20Mpa, temperature : 60°C, then raise the temperature to 90°C, keep the constant temperature for 30 minutes, after the pulp and residue are separated, dissolve vegetable oil, calcium carbonate, tricalcium phosphate, dipotassium hydrogen phosphate an...

Embodiment 2

[0065] Oat 11%, vegetable oil 3%, enzyme preparation (α-amylase 0.015%, β-amylase 0.0005%, neutral protease 0.001%, glucoamylase 0.015%, cellulase 0.0008%), calcium carbonate 0.2%, triphosphate Calcium 0.1%, dipotassium hydrogen phosphate 0.05%, and the balance is water.

[0066] Sorting stones, metals, wheat husks and other foreign objects in the oats, frying the sorted oats in an oven at 250°C for 60 minutes, then cooling to 25°C, adding the stir-fried oats to a pulverizer for grinding Make powder, control the temperature of hot water at 60°C, add enzyme preparation and obtained oat flour in sequence, start stirring, keep warm for 1.0h, obtain oat pulp base material, homogenize the oat pulp base material, homogenization pressure: 20Mpa, temperature : 60°C, then raise the temperature to 90°C, keep the constant temperature for 30 minutes, after the pulp and residue are separated, dissolve vegetable oil, calcium carbonate, tricalcium phosphate, dipotassium hydrogen phosphate an...

Embodiment 3

[0068] Oat 14.5%, vegetable oil 2.5%, enzyme preparation (α-amylase 0.015%, β-amylase 0.0005%, neutral protease 0.001%, glucoamylase 0.015%, cellulase 0.0008%), calcium carbonate 0.2%, triphosphate Calcium 0.1%, dipotassium hydrogen phosphate 0.05%, and the balance is water.

[0069] Sorting stones, metals, wheat husks and other foreign objects in the oats, frying the sorted oats in an oven at 250°C for 60 minutes, then cooling to 25°C, adding the stir-fried oats to a pulverizer for grinding Make powder, control the temperature of hot water at 60°C, add enzyme preparation and obtained oat flour in turn, start stirring, keep warm for 1.0h, obtain oat pulp base material, homogenize oat pulp base material, homogenization pressure: 20Mpa, temperature : 60°C, then raise the temperature to 90°C, keep at constant temperature for 30 minutes, after separating pulp and residue, dissolve vegetable oil, calcium carbonate, tricalcium phosphate, dipotassium hydrogen phosphate and other mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com