Non-aqueous electrolyte and battery containing same

A non-aqueous electrolyte and electrolyte technology, applied in the direction of electrolyte, secondary battery, secondary battery repair/maintenance, etc., can solve the problem of interface performance reduction, battery normal temperature cycle performance, high temperature cycle characteristic safety and high temperature storage performance reduction And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

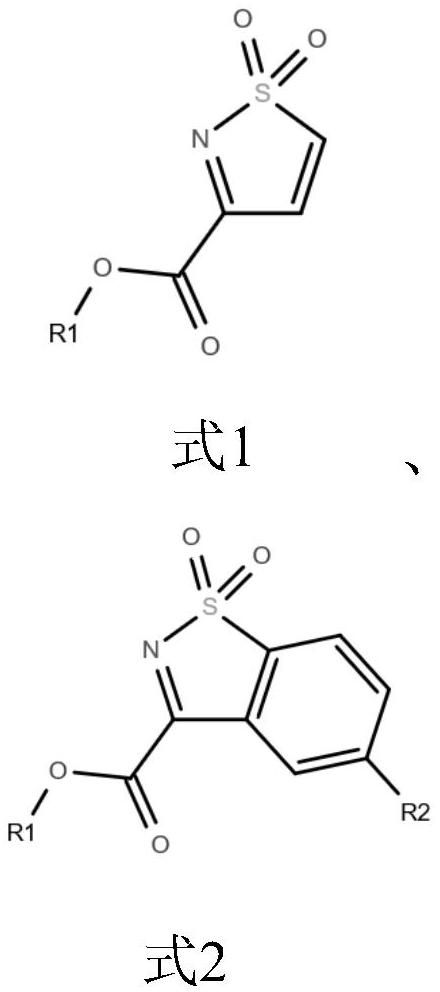

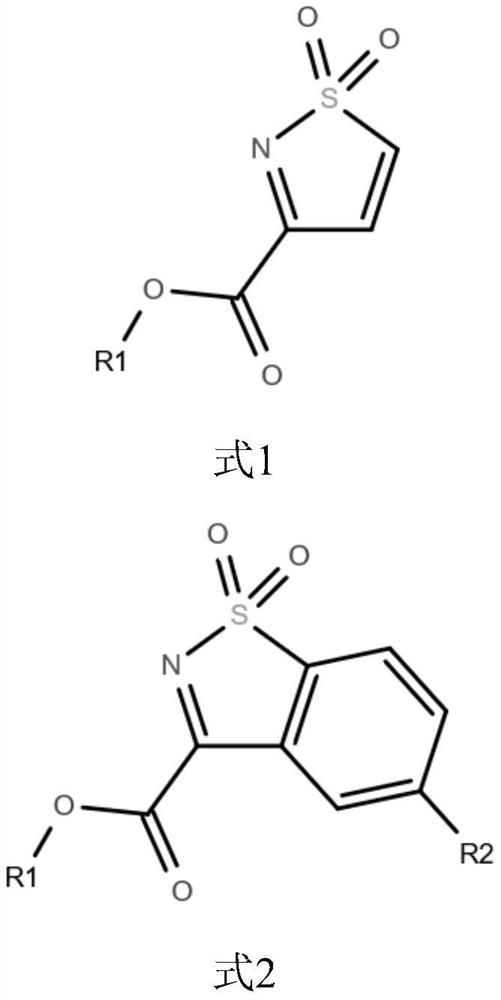

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a non-aqueous electrolytic solution, which is composed of cyclic carbonates, chain carbonates, lithium salts and additives.

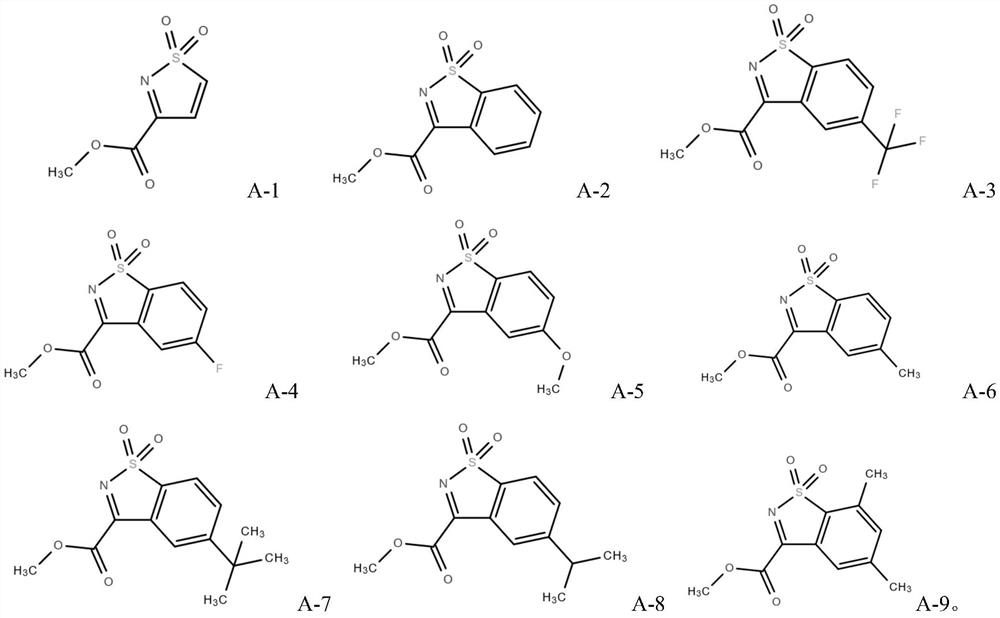

[0062] The additive is composed of isothiazole additive and non-isothiazole additive, the isothiazole additive is compound A-1, and the non-isothiazole additive is 1,4-butane sultone. The cyclic carbonate is ethylene carbonate, the chain carbonate is dimethyl carbonate, and the lithium salt is LiPF 6 .

[0063] The mass ratio of the cyclic carbonate and the chain carbonate is 1:2.5; the molar concentration of the lithium salt in the mixed solvent formed by the cyclic carbonate and the chain carbonate is 1.3mol / L; The quality of the thiazole additive is 0.5% of the total mass of the lithium salt, cyclic carbonate and chain carbonate; the quality of the non-isothiazole additive is the lithium salt, cyclic carbonate and chain carbonate 3.0% of the total mass.

[0064] The preparation method of the above-mentioned non-aque...

Embodiment 2

[0066] This embodiment provides a non-aqueous electrolytic solution, which is composed of cyclic carbonates, chain carbonates, lithium salts and additives.

[0067] The additive is composed of an isothiazole additive and a non-isothiazole additive, the isothiazole additive is compound A-3, and the non-isothiazole additive is 1,3-propane sultone and 1,4- Butane sultone (the mass ratio of 1,3-propane sultone and 1,4-butane sultone is 1:2). The cyclic carbonate is γ-butyrolactone, the chain carbonate is ethyl methyl carbonate, and the lithium salt is LiPF 6 .

[0068] The mass ratio of the cyclic carbonate and the chain carbonate is 1:2; the molar concentration of the lithium salt in the mixed solvent formed by the cyclic carbonate and the chain carbonate is 1.0mol / L; the iso The quality of the thiazole additive is 0.1% of the total mass of the lithium salt, cyclic carbonate and chain carbonate; the quality of the non-isothiazole additive is the lithium salt, cyclic carbonate a...

Embodiment 3

[0071] This embodiment provides a non-aqueous electrolytic solution, which is composed of cyclic carbonates, chain carbonates, lithium salts and additives.

[0072] The additive is composed of an isothiazole additive and a non-sulfonic anhydride additive, the sulfonic anhydride additive is compound A-5, and the non-isothiazole additive is adiponitrile and lithium difluorophosphate (adiponitrile and difluorophosphate The mass ratio of lithium fluorophosphate is 1:1). The cyclic carbonate is propylene carbonate, the chain carbonate is diethyl carbonate, and the lithium salt is LiPF 6 .

[0073] The mass ratio of the cyclic carbonate and the chain carbonate is 1:3; the molar concentration of the lithium salt in the mixed solvent formed by the cyclic carbonate and the chain carbonate is 1.5mol / L; The quality of thiazole additives is 1.0% of the total mass of the lithium salt, cyclic carbonate and chain carbonate; the quality of the non-isothiazole additive is the lithium salt, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com