Laser ultrasonic nondestructive testing equipment and method adopting light deflection method

A laser ultrasonic and non-destructive testing technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems affecting the signal strength of laser ultrasonic flaw detection, signal synchronization delay, complex structure, etc., to achieve easy debugging equipment, The effect of portable equipment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

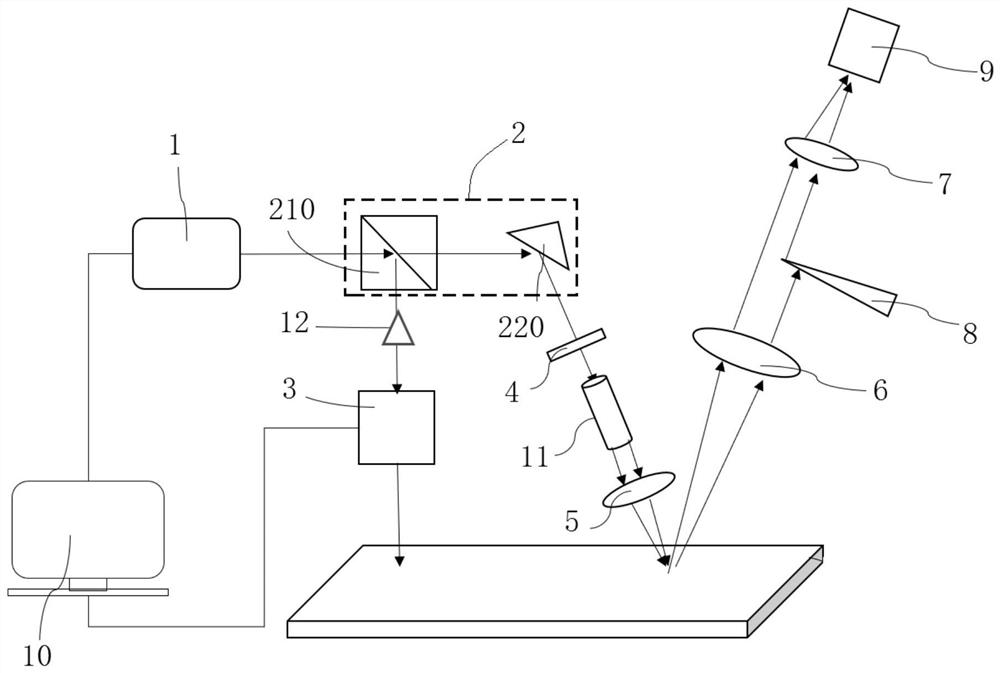

[0043] Such as figure 1 As shown, a laser ultrasonic non-destructive testing equipment by optical deflection method, including:

[0044] Laser 1, beam splitting device 2, vibrating mirror 3, energy attenuation device 4, first positive lens 5, second positive lens 6, third positive lens 7, shading device 8, photodiode 9 and signal processing terminal 10;

[0045] The laser 1 is used to emit pulsed laser;

[0046] The beam splitting device 2 is arranged at the exit end of the laser 1. The beam splitting device 2 has two exit ends. The pulsed laser light emitted by the laser 1 enters the beam splitting device 2 and is divided into two beams by the beam splitting device 2. shoot out from one exit end;

[0047] The vibrating mirror 3 is arranged at one of the exit ends of the beam splitting device 2, and the pulse laser emitted from one of the exit ends of the beam splitting device 2 will enter the vibrating mirror 3, and then the vibrating mirror 3 converts the incoming point la...

Embodiment 2

[0058] Such as figure 1 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0059] The optical deflection method laser ultrasonic nondestructive testing equipment also includes an optical switch 12,

[0060] The optical switch 12 is arranged between the output end of the beam splitting device 2 and the input end of the vibrating mirror 3. The optical switch 12 is used to realize the on-off of the light, so as to control the light output at point intervals. The sensitivity of the optical switch 12 should reach more than 1ms .

Embodiment 3

[0062] Such as figure 1 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1 or 2, which is specifically as follows:

[0063] The beam splitting device 2 includes: a beam splitting prism 210 and a mirror 220;

[0064] The beam splitting prism 210 is arranged at the output end of the laser 1, and the beam splitting prism 210 has two output ends;

[0065] The pulsed laser light emitted by the laser 1 enters the beam-splitting prism 210, and is divided into two beams by the beam-splitting prism 210, and then emitted from the two output ends respectively;

[0066] Reflector 220, which is arranged at one of the exit ends of beam splitting prism 210;

[0067] The oscillating mirror 3 and the energy attenuating device 4 are respectively arranged at the other output end of the beam splitting prism 210 and the reflection end of the mirror 220 .

[0068] The pulse laser emitted from one of the output ends of the beam-splitting prism 210 ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com