Speckle pattern-based mirror surface object three-dimensional measurement method

A technology of three-dimensional measurement and speckle pattern, which is applied to measuring devices, instruments, optical devices, etc., to avoid error accumulation, reduce subset size, and improve measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The examples of the present invention are described in further detail below in conjunction with the accompanying drawings, but the examples are not intended to limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

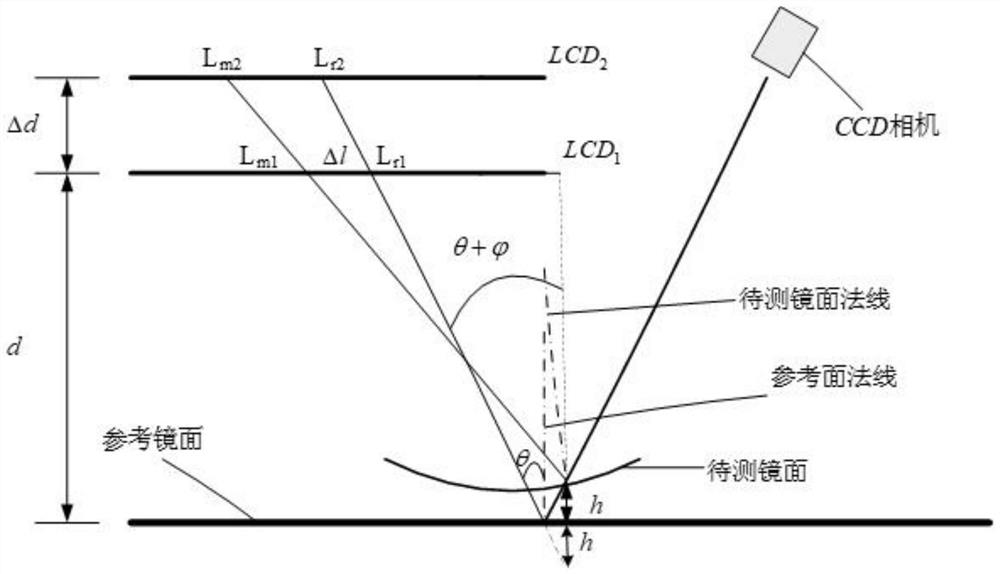

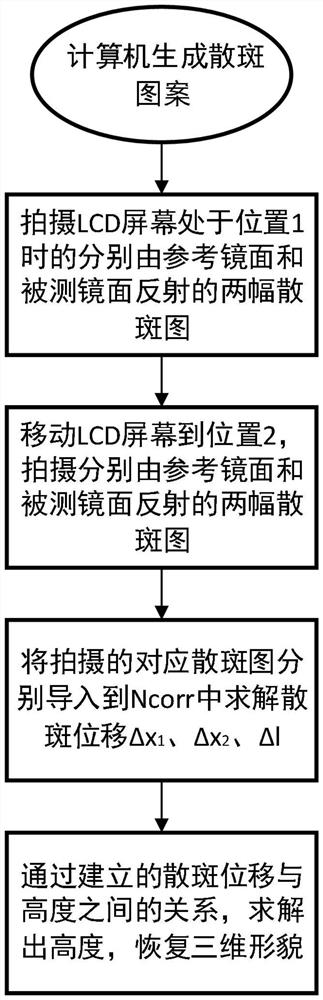

[0019] A three-dimensional measurement method for specular objects based on speckle patterns, the principle of which is as follows figure 1 As shown, it includes the acquisition device CCD camera, the projection device LCD, the reference mirror, the mirror to be tested, and the computer. First use a computer to generate a pre-designed speckle pattern, and then use the projection device LCD to project the speckle pattern onto the reference mirror and the mirror to be tested. After mirror reflection, the reflected speckle pattern is collected by the CCD camera; and then through The precision translation stage moves the projection device LCD for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com