Organic peroxide microemulsion type initiator and preparation method thereof

An organic peroxide and microemulsion technology, applied in the field of initiator preparation, can solve problems such as poor initiation efficiency, difficulty in reducing particle size, and short storage time, so as to reduce process cost, maintain stable heat release, and improve reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

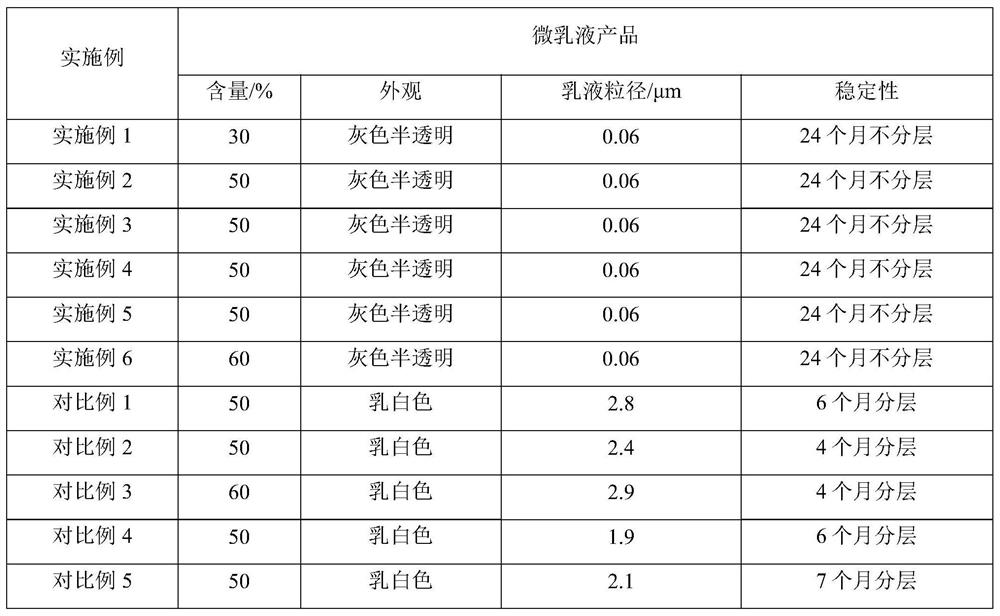

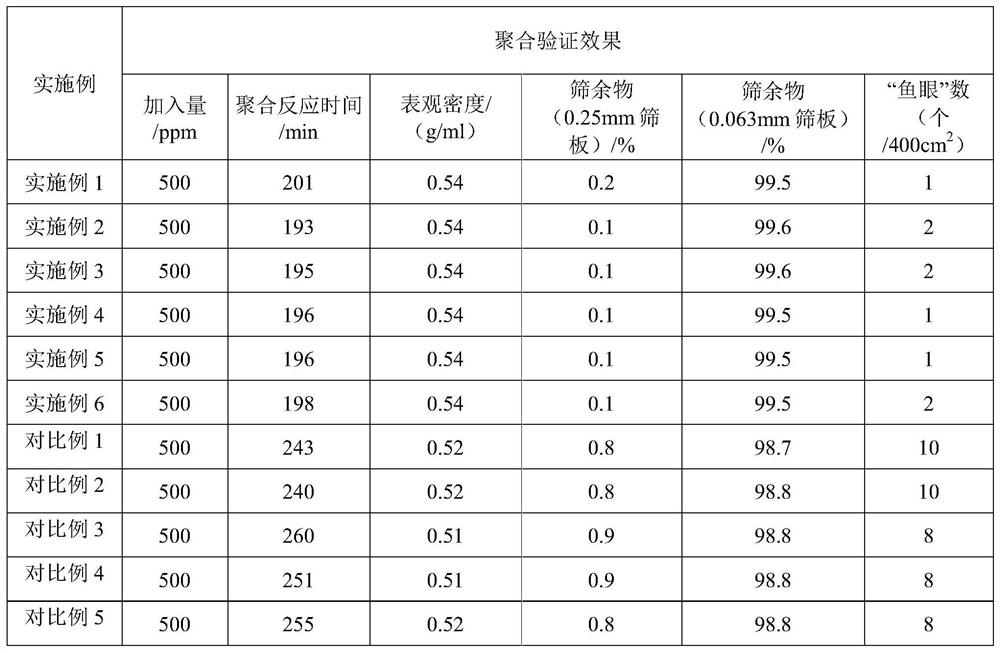

Examples

preparation example Construction

[0033] The present invention also provides the preparation method of above-mentioned product, and its technology is mainly divided into two steps:

[0034] (1) In the first step, first add the main emulsifier, main dispersant, auxiliary dispersant, antifreeze, and deionized water into the reactor for mixing, and stir for 10 minutes. The temperature in the reactor should be controlled below 0°C.

[0035] (2) In the second step, put the product synthesized in the first step into the oil phase emulsification tank, stir and shear for 30 minutes; then slowly add the co-emulsifier into the tank until the appearance of the material in the tank changes from milky white to half After it becomes transparent, stop the dropwise addition, and continue to cut for 10 minutes before the preparation is completed.

[0036] The present invention optimizes the component types and proportions of the product, and optimizes the design of the overall process, especially adopts the microemulsion prepa...

Embodiment 1

[0039] Formula: OP-10 1%, n-butanol 6%, PVA-4788 5%, CMC 0.2%, methanol 20%, cumyl peroxyneodecanoate 32%, and the balance is deionized water.

[0040] The preparation method is to add OP-10, PVA-4788, CMC 0.2%, methanol, and deionized water to the reactor for mixing, start stirring, control the temperature below 0°C, stir for 10 minutes, then transfer to the oil phase emulsification tank, stir and shear for 30 minutes, Then start to slowly drop n-butanol, stop the dripping after the material appearance in the kettle changes from milky white to translucent rapidly, continue to cut after 10min and complete the preparation to obtain a microemulsion type initiator product with a content of 30%.

Embodiment 2

[0042] Formula: OP-10 1%, n-butanol 8%, PVA-4788 4%, CMC 0.2%, methanol 20%, cumyl peroxyneodecanoate 60%, and the balance is deionized water.

[0043] The preparation method is to add OP-10, PVA-4788, CMC 0.2%, methanol, and deionized water to the reactor for mixing, start stirring, control the temperature below 0°C, stir for 10 minutes, then transfer to the oil phase emulsification tank, stir and shear for 30 minutes, Then start to slowly drop n-butanol, stop the dripping after the material appearance in the kettle changes from milky white to translucent rapidly, continue to cut after 10min and complete the preparation to obtain a microemulsion type initiator product with a content of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com