Flowerpot separating device and method suitable for stacking of plastic flowerpots in various shapes

A technology of plastic flower pots and separation devices, which is applied in the directions of destacking, transportation and packaging of objects, conveyors, etc., can solve the problems of cumbersome operation, excessive rotation of the pot body, frictional static electricity, uncontrollable falling position and posture, etc., to achieve separation. Process smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

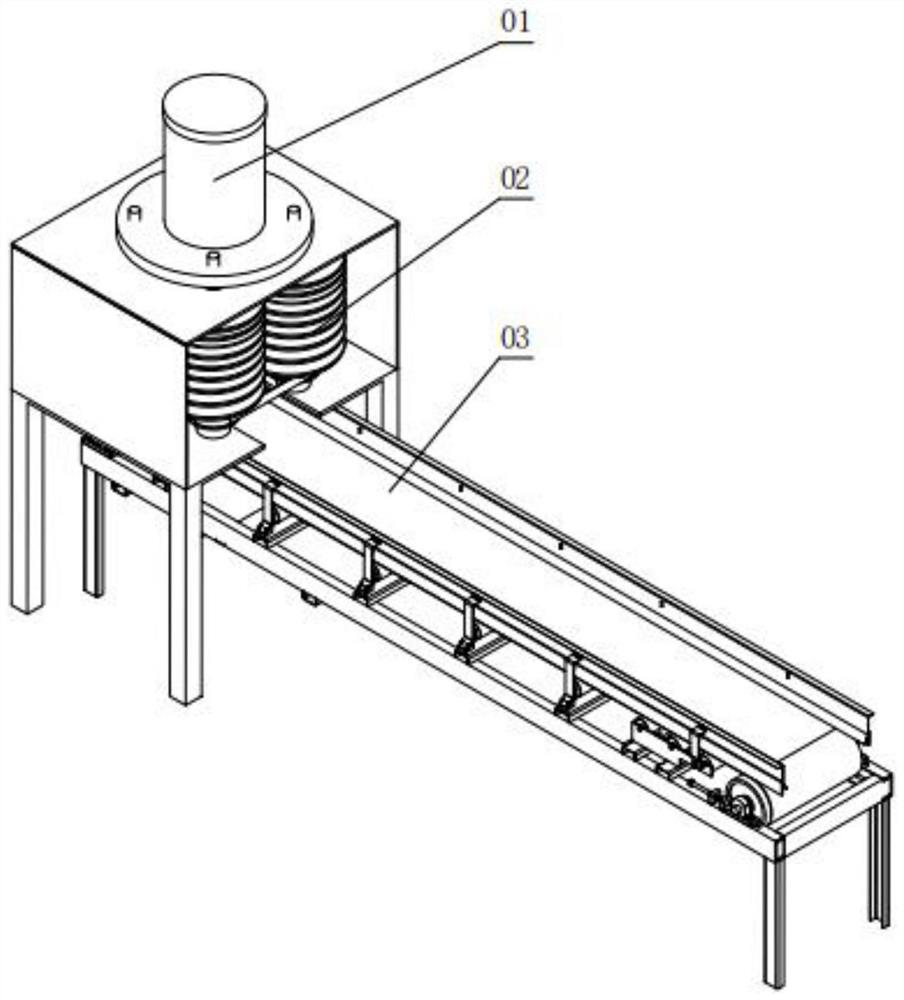

[0038] Such as figure 1 As shown, the flowerpot separation device adapted to stacking plastic flowerpots of various shapes includes a positioning and carrying mechanism 01, a flowerpot separating mechanism 02 and a single flowerpot transportation mechanism 03; the positioning and carrying mechanism 01 is used to limit the flowerpots only Can move in the vertical direction, or slightly deflected in the horizontal plane; the flower pot separation mechanism 02 is used to separate the stacked flower pots into a single drop onto the single flower pot transport mechanism 03; the single flower pot transport mechanism 03 is used for transportation A single flowerpot separated by the flowerpot separation mechanism 02.

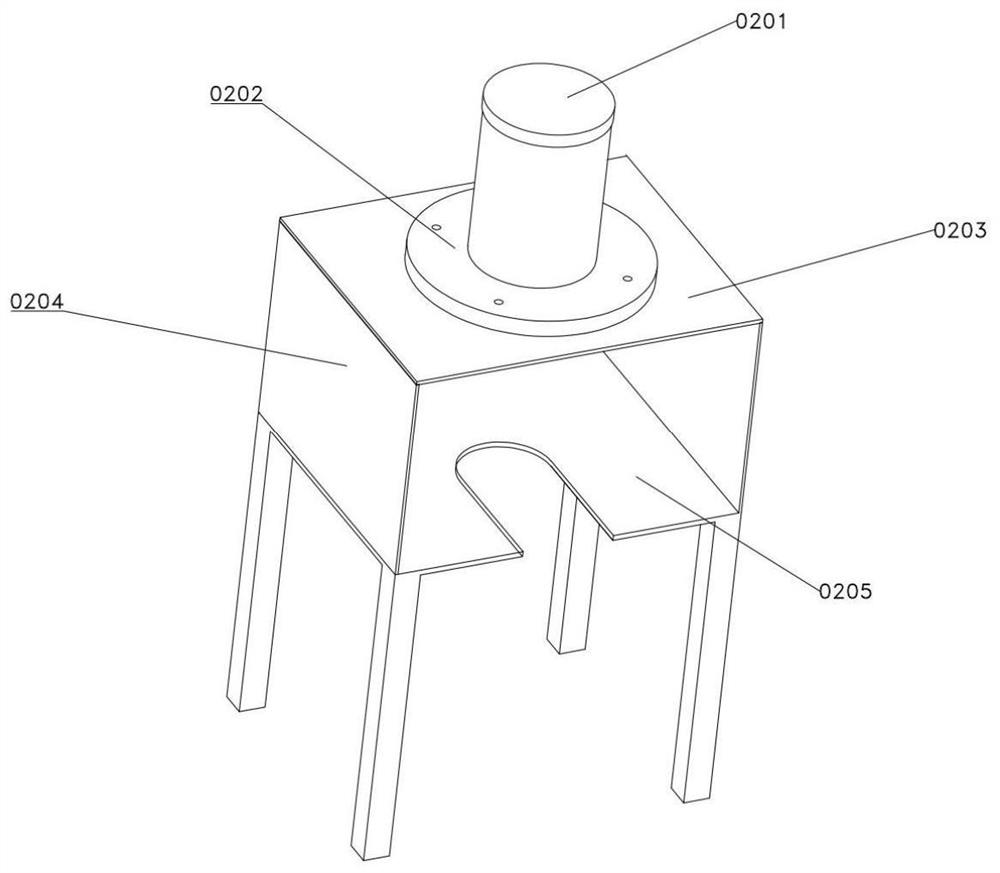

[0039] Such as figure 2 and 3 As shown, the positioning and bearing mechanism 01 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com