Fault diagnosis method for main bearing of manufacturing equipment based on digital twinborn body

A fault diagnosis and main bearing technology, applied in mechanical bearing testing, measuring devices, character and pattern recognition, etc., can solve problems such as signal filtering expert experience dependence, achieve high practical significance, high autonomy, improve accuracy and effectiveness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Example 1: Bearing outer ring failure.

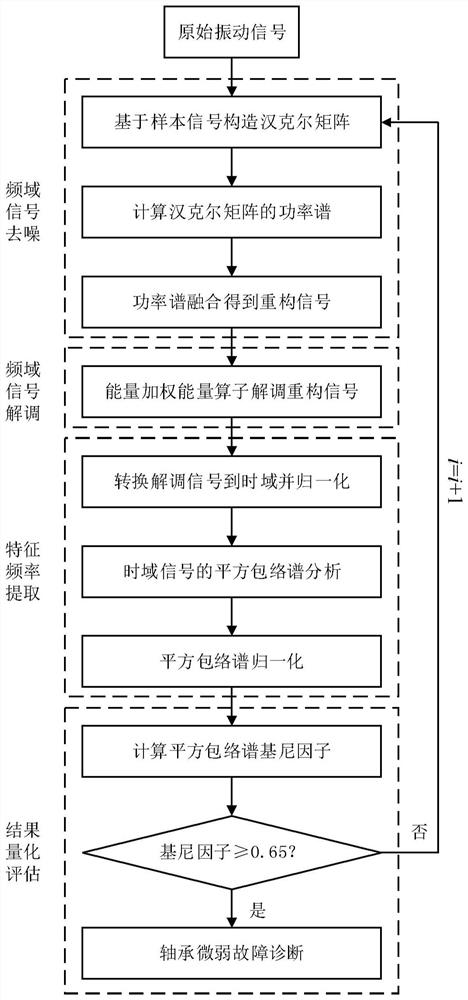

[0073] See attached figure 1 As shown, the embodiment of the present application discloses a fault diagnosis method for the main bearing of manufacturing equipment based on digital twins, including:

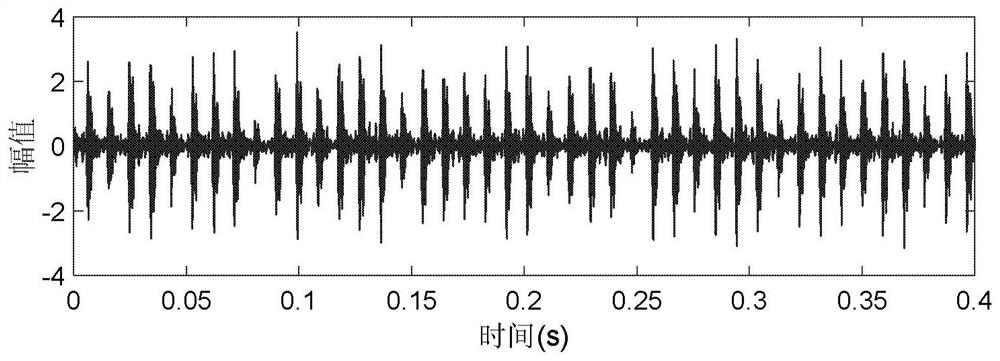

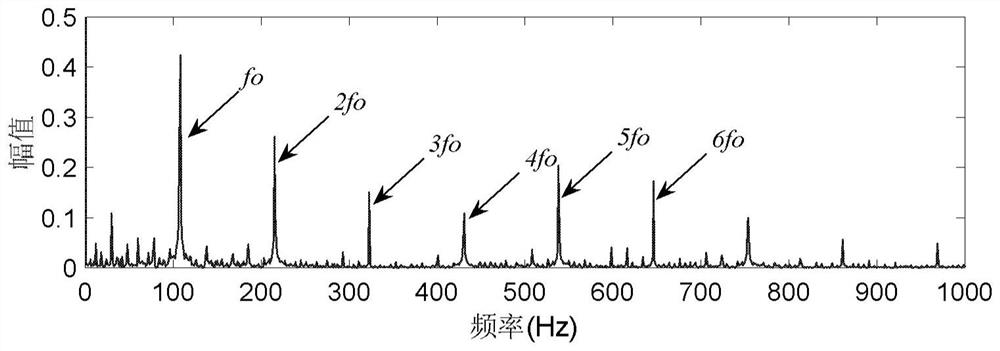

[0074] S1, based on the data acquisition device to obtain the real-time vibration signal of the bearing, as shown in Figure 2(a) is the fault signal of the outer ring of the bearing, because the fault impact is more obvious, so it can be detected from the envelope spectrum shown in Figure 2(b) to the fault characteristic frequency of the outer ring of the bearing. In order to verify the outstanding advantages of this application, Gaussian white noise interference is added to the collected signal. The time domain and frequency domain of the signal after the noise are added are shown in Figure 2(c) and Figure 2(d), respectively. It can be seen from the figure that the original The signal has been completely covered by noise, and the...

Embodiment 2

[0109] Example 2: Bearing inner ring failure.

[0110] See attached figure 1 As shown, the embodiment of the present application discloses a fault diagnosis method for the main bearing of manufacturing equipment based on digital twins, including:

[0111] S1, based on the data acquisition device to obtain the real-time vibration signal of the bearing, as shown in Figure 4(a) is the fault signal of the inner ring of the bearing, because the fault impact is more obvious, so it can be detected from the envelope spectrum shown in Figure 4(b) to the fault characteristic frequency of the inner ring of the bearing. In order to verify the outstanding advantages of this application, Gaussian white noise interference is added to the collected signal. The time domain and frequency domain of the signal after adding noise are shown in Figure 4(c) and Figure 4(d), respectively. It can be seen from the figure that the original The signal has been completely covered by noise, and the charac...

Embodiment 3

[0129] Example 3: Bearing rolling element failure.

[0130] See attached figure 1 As shown, the embodiment of the present application discloses a fault diagnosis method for the main bearing of manufacturing equipment based on digital twins, including:

[0131] S1, based on the data acquisition device to obtain the real-time vibration signal of the bearing, as shown in Figure 6(a) is the fault signal of the bearing rolling body, because the fault impact is more obvious, so it can be detected from the envelope spectrum shown in Figure 6(b) to the characteristic frequency of bearing rolling element faults. In order to verify the outstanding advantages of this application, Gaussian white noise interference is added to the collected signal. The time domain and frequency domain of the signal after adding noise are shown in Figure 6(c) and Figure 6(d), respectively. It can be seen from the figure that the original The signal has been completely covered by noise, and the characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com