Charging and discharging test method for accurately monitoring cycle life of lithium ion battery

A lithium-ion battery, charging and discharging testing technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems that affect the accuracy of battery performance testing, Li+ can't come out, battery life impact, etc., to achieve an intuitive and effective healthy state , Novel method, accurate judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

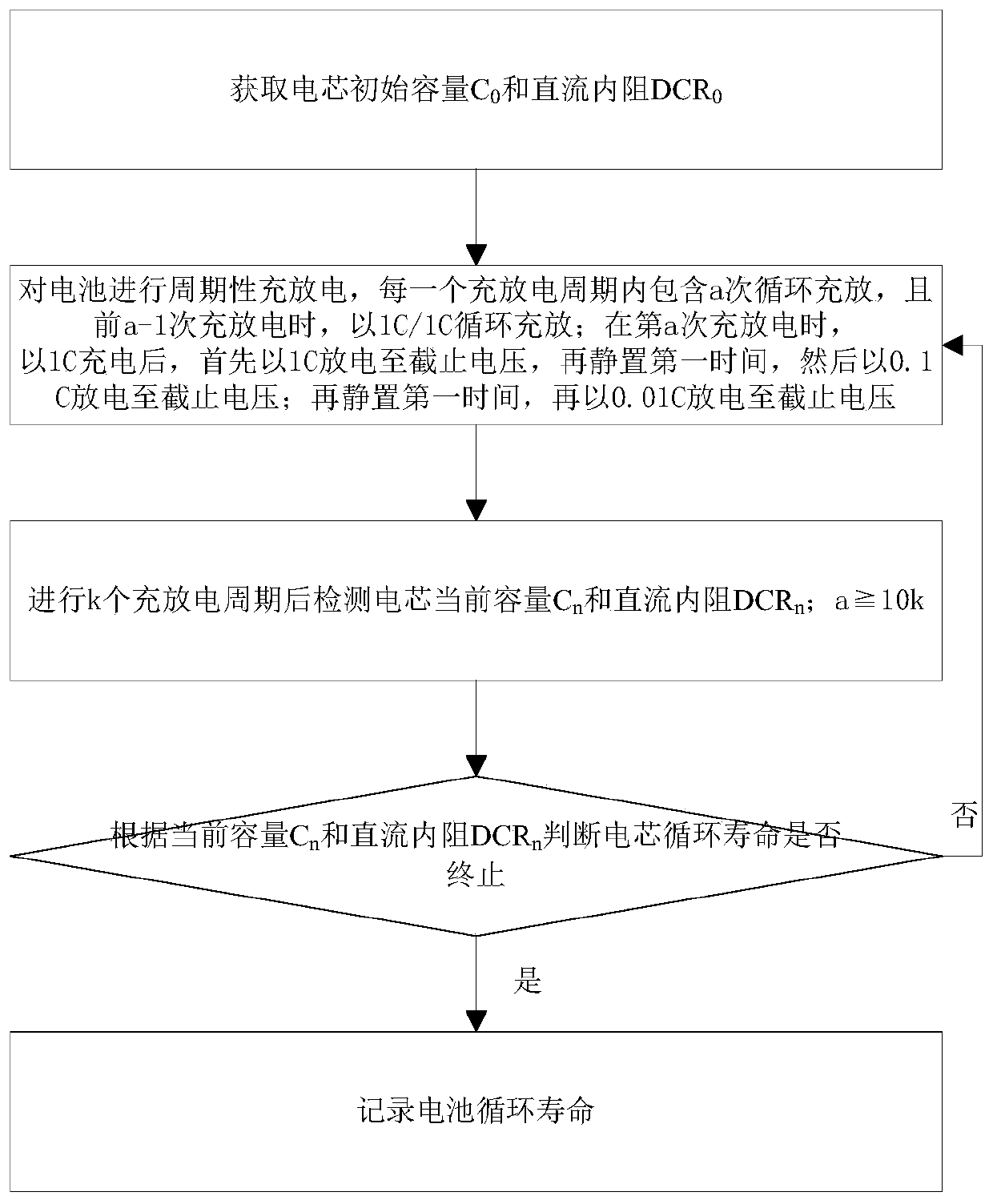

Method used

Image

Examples

Embodiment 1

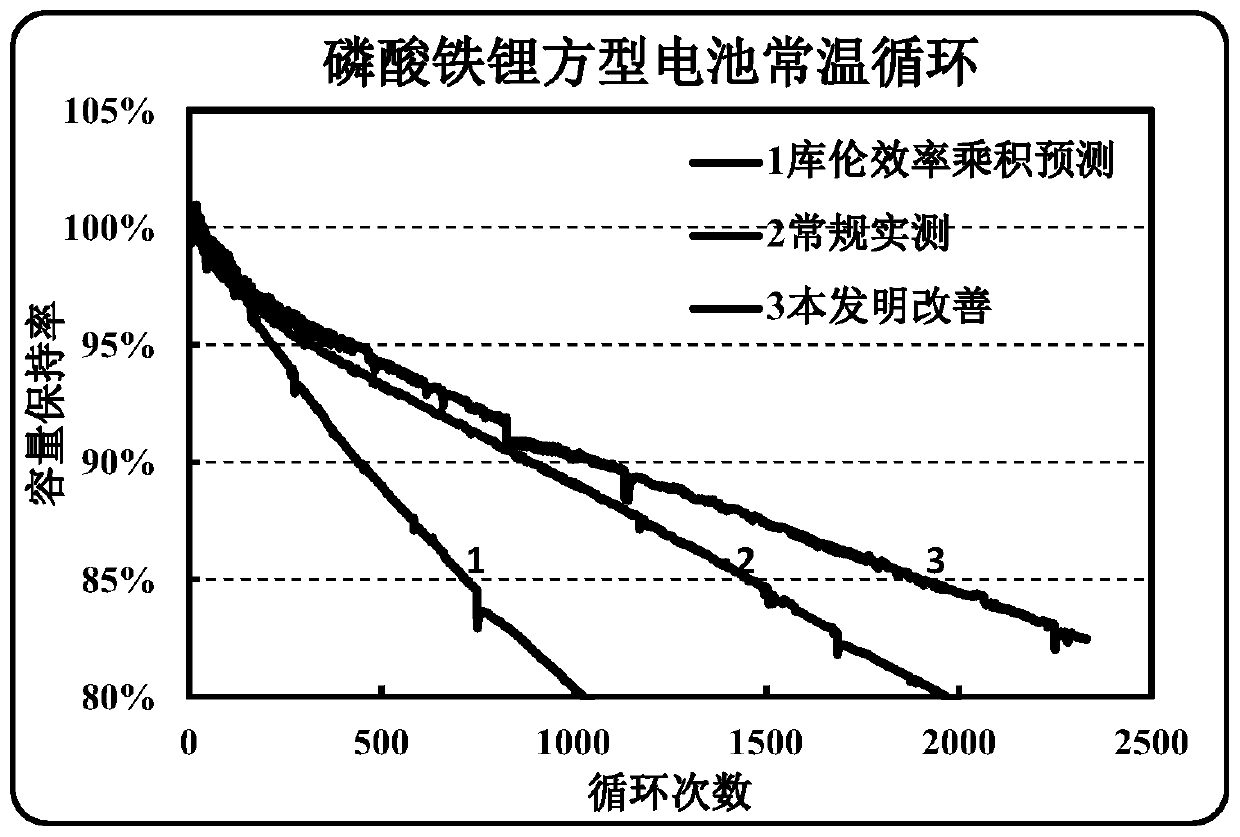

[0033] Select two square lithium iron phosphate batteries with better consistency, one of which carries out 1C / 1C cycle according to the conventional charge and discharge method, and the other cycle according to the charge and discharge method provided in the present invention; other conditions such as current, The cut-off voltage, rest time, test cabinet and external environment are all consistent. Loop results like figure 2 as shown, figure 2 The depolarization-related data in the process has been omitted, and only the normal cycle data are selected for comparison. It can be seen that the predicted life according to the product of the Coulomb efficiency value per cycle is about 1000 weeks, while the measured life is 2000 weeks, and the predicted life only accounts for 50% of the measured life, indicating that cyclic polarization causes more lithium deposition on the negative electrode, and the cycle is effective Lithium becomes less, and more lithium is extracted from th...

Embodiment 2

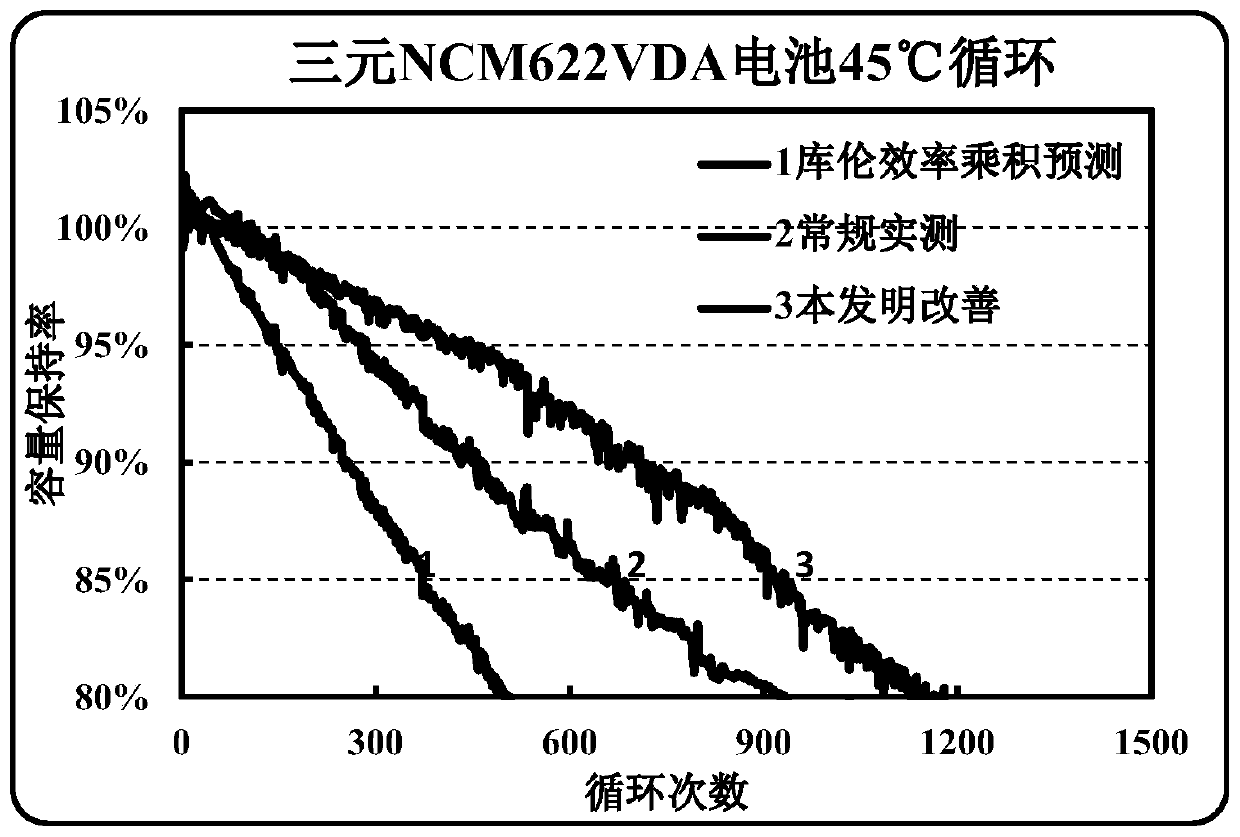

[0035] Select two VDA ternary 622 batteries with better consistency, one of which carries out 1C / 1C cycle according to the conventional charge and discharge method, and the other cycle according to the charge and discharge method provided in the present invention; other conditions such as current, cut-off The voltage, resting time, test cabinet and external environment are all consistent. Loop results like image 3 as shown, image 3The depolarization-related data in the process has been omitted, and only the normal cycle data are selected for comparison. It can be seen that the predicted life according to the product of the Coulomb efficiency value per cycle is about 500 weeks, while the measured life is 930 weeks, and the predicted life only accounts for about 54% of the measured life, indicating that cyclic polarization still leads to more lithium deposition on the negative electrode , so that the circulating effective lithium becomes less, and more lithium needs to be ex...

Embodiment 3

[0037] Choose two soft-pack ternary Ni85 batteries with good consistency, wherein one carries out 1C / 1C cycle according to the conventional charge and discharge method, and the other cycle according to the charge and discharge method provided in the present invention; other conditions such as current, The cut-off voltage, rest time, test cabinet and external environment are all consistent. Loop results like Figure 4 as shown, Figure 4 In , the depolarization-related data in the process have been omitted, and only the normal cycle data are selected for comparison. It can be seen that the predicted life according to the product of the Coulomb efficiency value per circle is about 450 weeks, while the measured life is 900 weeks, and the predicted life only accounts for about 50% of the measured life, indicating that cyclic polarization still leads to more lithium deposition on the negative electrode , so that the circulating effective lithium becomes less, and more lithium nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com