Glue production quality monitoring method based on turbidity analysis

A production quality and quality monitoring technology, applied in transmittance measurement, phase influence characteristic measurement, etc., can solve the problems of large blind motion in the production process, uneven light transmittance and smoothness of glue block quality, and fluctuation of glue quality, etc. Achieve the effect of improving product quality, guiding standardized development, and avoiding volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

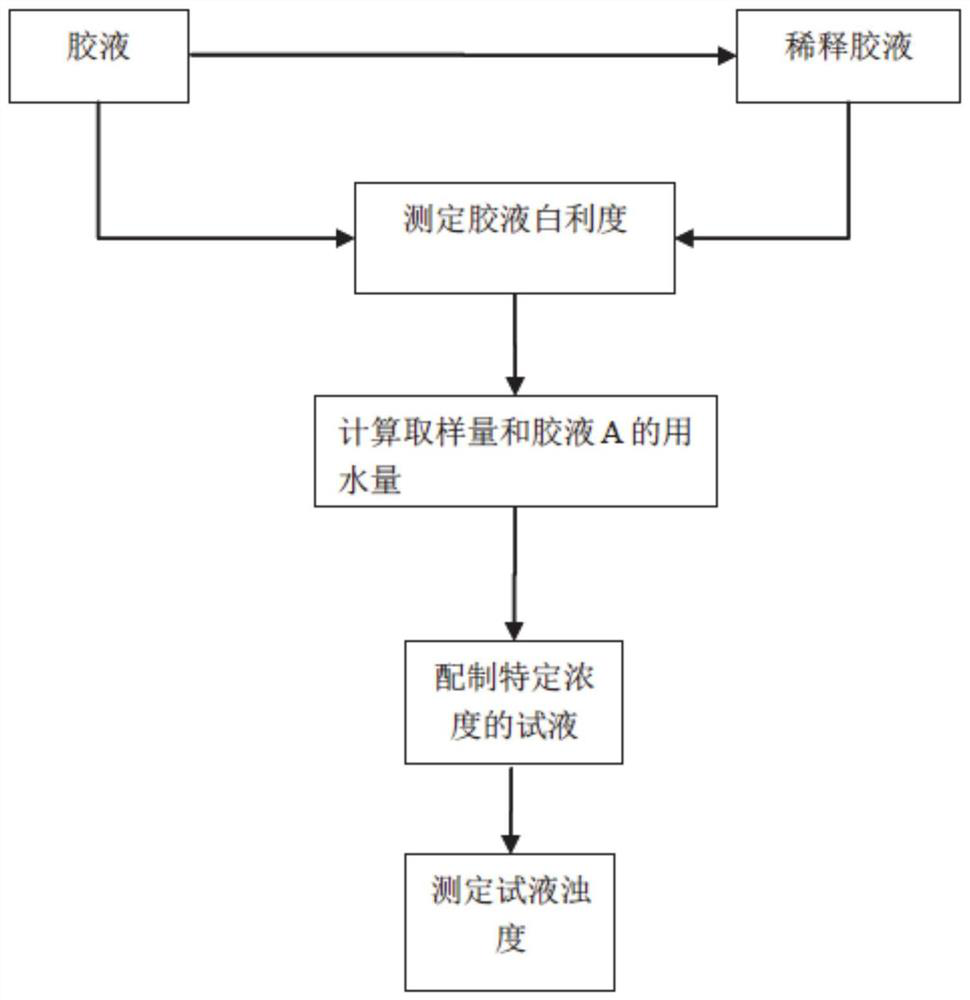

Method used

Image

Examples

Embodiment 1

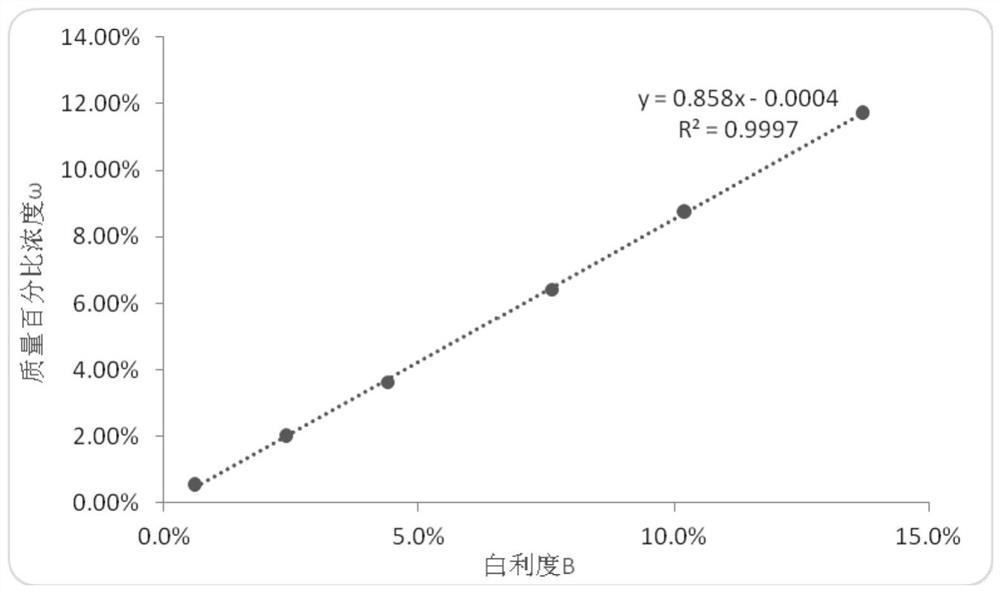

[0048] Example 1, Concentration Analysis of Conventional Ejiao Extract

[0049] Experimental materials: conventional gelatin production process during the production of gel extracts.

[0050] Linear relationship analysis method:

[0051] (1) Determination of the concentration of the plastic concentration:

[0052] The collapse of the extracted section is mixed, placed in a plug bottle, cool to room temperature, and used as a working fluid;

[0053] Take the hydraulic working fluid about 10g, placed in a weighing bottle with numbered and constant weight, precision weighing, drying at a 105 ° C oven to constant weight, precision weighing, calculating the mass percent concentration of the glue;

[0054] (2) Preparation of a series of standard liquid concentrations:

[0055] With the working fluid as the mother liquor, the weight method is used to form a series of standard concentrations (concentrations in ω);

[0056] (3) Determination of the whiteness of standard liquid:

[0057] Ta...

Embodiment 2

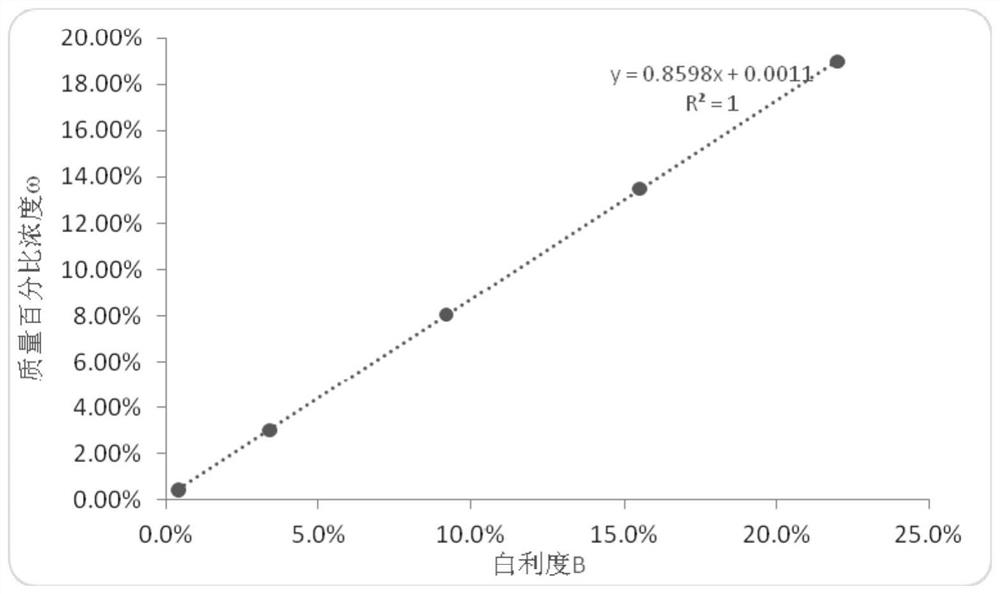

[0073] Example 2, concentration of glue concentration of concentration segments

[0074] Experimental materials: Concentrated segment gel: (conventional Ejiao) chemical glue juice filtered the concentration of the process.

[0075] Linear relationship analysis method:

[0076] (1) Determination of the concentration of the plastic concentration:

[0077] Mix the concentrate of the concentrated section to mix, placed in a plug bottle, cooled to room temperature, spare;

[0078] Take a glue sample, placed in a weighing bottle that has been numbered and constant, is precisely weighing, dried to the oven at 105 ° C to constant weight, precision weighing, calculating the concentration of the glue mass;

[0079] (2) Preparation of a series of standard liquid concentrations:

[0080] The above glue sample was formulated into a concentration of working fluid, and the working fluid was a mother liquor, and the weight method was used as a series of standard concentrations (concentrations in ...

Embodiment 3

[0103] Example 3, the concentration analysis in the foam

[0104] Experimental materials: Conventional Ejiao (20210422) During the production process, the foam step is sampled, purified with purified water.

[0105] Analytical method:

[0106] (1) Solution dilution method:

[0107] In the plug triangle bottle, the magneton, peeled, take the 10g gel, add the jug, accurately weigh the added glue amount M 1 , Exactly 0.01 g, add about 10 g of pure water, stir well. Cool to room temperature, weigh the total glue (M 2 ), Accurate to 0.01g. As the test solution 1.

[0108] (2) White Levity Test Method:

[0109] Take 1 drop of the test solution to the refractometer cover, test the whiteness of the test liquid, record the whiteness value B 1 .

[0110] (3) Calculation of gel fluid:

[0111] The concentration of the glue is estimated according to the following formula:

[0112]Ω = kb 1 × M 2 / M 1 × 100% .................................... (1)

[0113] Central B 1 In order to measure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com