Ca-containing magnesium alloy sacrificial anode and preparation method and application thereof

A sacrificial anode, magnesium alloy technology, applied in mechanical equipment and other directions, can solve the problems of magnesium alloy self-loss, material surface particle shedding, fast corrosion rate, etc., to achieve the effect of improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] Another aspect of the present invention provides a method for preparing a Ca-containing magnesium alloy sacrificial anode, comprising the following steps:

[0072] In the presence of a protective substance, Mg is melted, then Al, Zn and Ca are added, stirred, kept warm and left standing, and cooled to obtain the Ca-containing magnesium alloy sacrificial anode. The preparation method is simple, convenient to operate, easy to process and shape, and is suitable for industrial production.

[0073] According to some embodiments of the invention, the protective substance includes a protective gas and / or a covering agent. The protective substance is used to isolate the air, and the purpose is to prevent the oxidation or combustion of the metal during the preparation of the magnesium alloy sacrificial anode, especially the low ignition point of magnesium, which is easy to burn and needs protection.

[0074] According to some embodiments of the present invention, the protective...

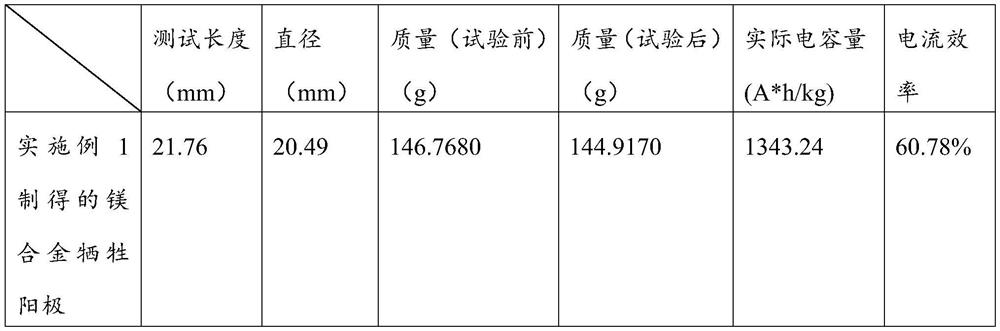

Embodiment 1

[0104] A Ca-containing magnesium alloy sacrificial anode, by mass percentage, including Al 5.5%, Zn 3.5%, Mn0.2%, Ca 0.1%, Si<0.001%, Fe<0.001%, Cu<0.001%, Ni< 0.001%, Mg balance.

[0105] The preparation method of the magnesium alloy sacrificial anode comprises the following steps:

[0106] in CO 2and SF 6 In a protective gas atmosphere, in a heating furnace, use graphite crucible as a container to melt magnesium ingots, then add aluminum ingots, zinc ingots, magnesium-manganese master alloys and magnesium-calcium master alloys in sequence, stir to remove slag, and then keep warm at 720°C Stand still for 20 minutes, pour into a round rod mold and air cool to obtain a rod-shaped magnesium alloy sacrificial anode.

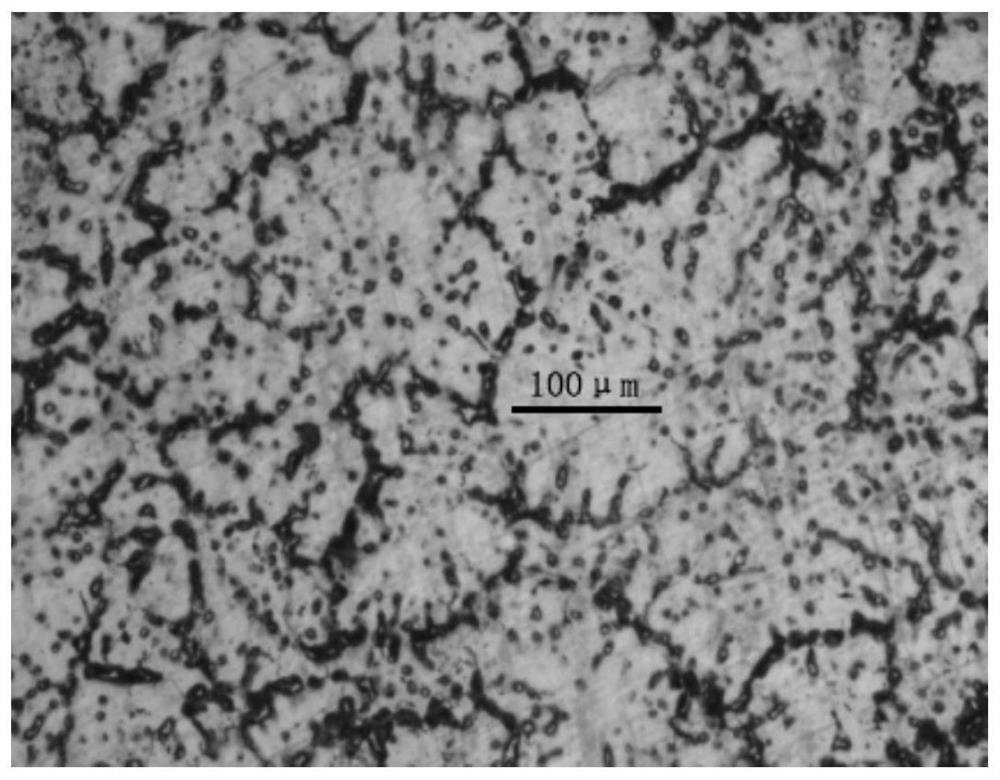

[0107] figure 2 It is a metallographic micrograph of the magnesium alloy sacrificial anode prepared in Example 1 of the present invention. figure 2 The small black area in the middle is the β phase (Mg 17 Al 12 phase), and the large off-white area is the α ...

Embodiment 2

[0117] A Ca-containing magnesium alloy sacrificial anode, by mass percentage, including Al 6.3%, Zn 2.5%, Mn0.4%, Ca 0.2%, Si<0.001%, Fe<0.001%, Cu<0.001%, Ni< 0.001%, Mg balance.

[0118] The preparation method of the magnesium alloy sacrificial anode comprises the following steps:

[0119] in CO 2 and SF 6 Under protective gas atmosphere, in a heating furnace, use graphite crucible as a container to melt magnesium ingots, then add aluminum ingots, zinc ingots, magnesium-manganese master alloys and magnesium-calcium master alloys in sequence, stir to remove slag, and then keep warm at 700 ° C Stand still for 40 minutes, pour into a round rod mold and air cool to obtain a rod-shaped magnesium alloy sacrificial anode.

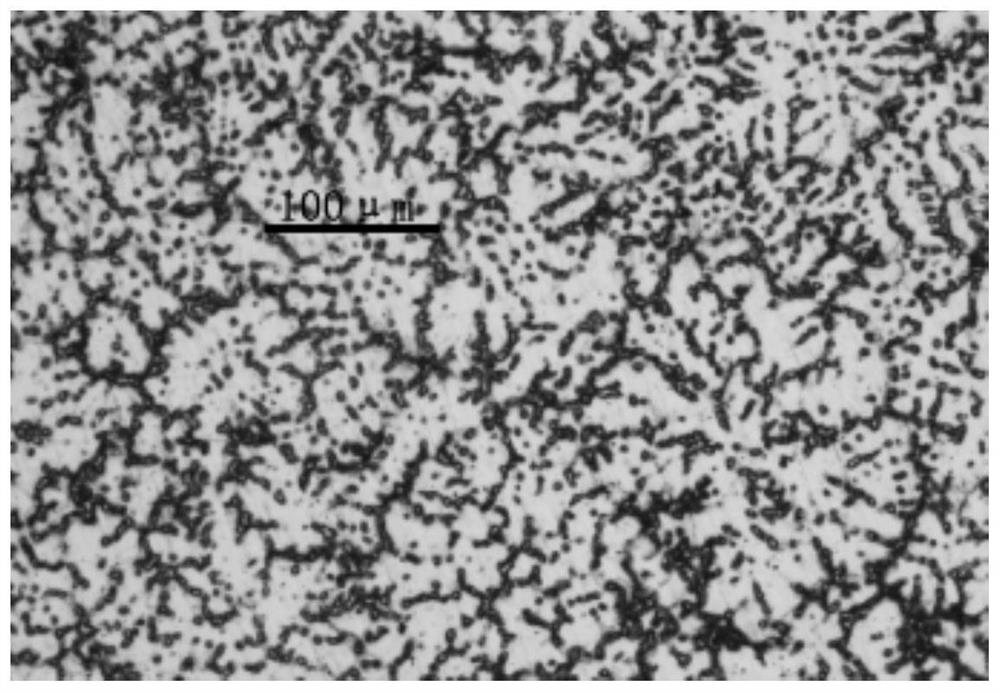

[0120] The current efficiency, corrosion resistance, open circuit potential and closed circuit potential of the rod-shaped magnesium alloy sacrificial anode prepared in Example 2 were tested according to GB / T17848-1999. Before testing the closed-circuit pote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com