Lamination of permanent magnet motor stator core

A stator core and permanent magnet motor technology, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of potential safety hazards and the same cut size, and achieve the effect of improving safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

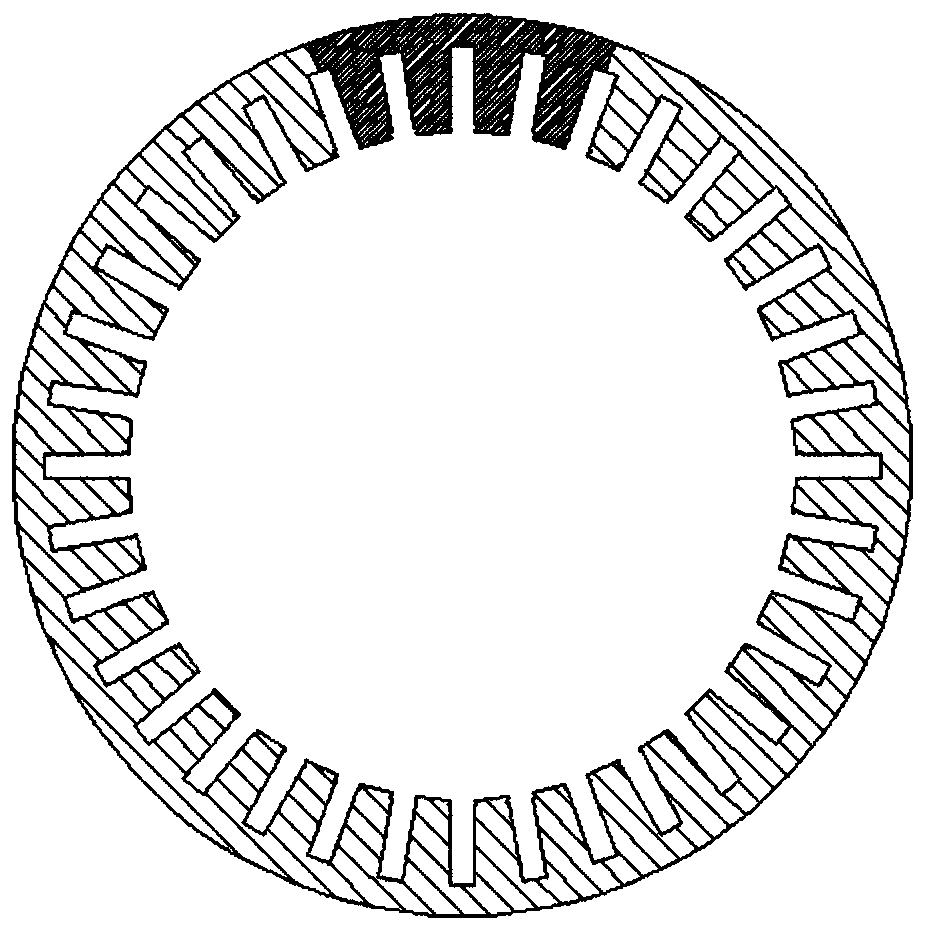

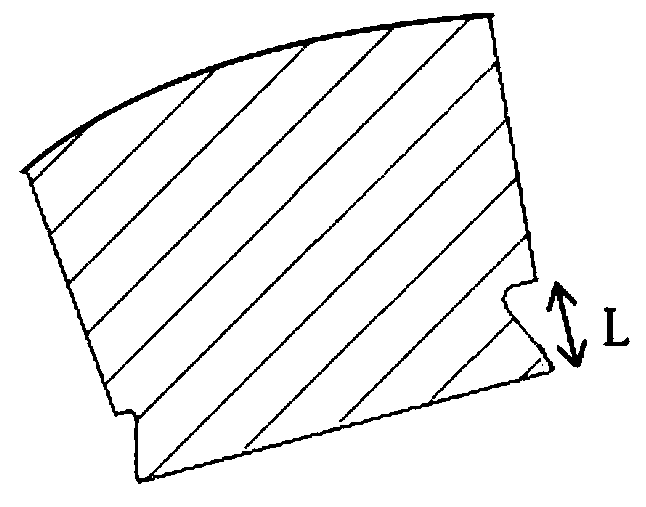

[0022] The stator iron core of the permanent magnet motor of the present embodiment is formed by stacking a plurality of annular laminations, and the annular laminations are an annular structure (such as figure 1 As shown, the shaded part is a stator segment), the stator segment is provided with a stator slot 5 with a slot depth of H1, and both sides of the stator slot 5 are provided with triangular cutouts for placing slot wedges to prevent the conductors in the stator slot 5 from protruding .

[0023] When in use, the annular laminations are placed vertically, and the cutouts on the annular laminations include cutouts A1, B2, C3 at the notch of the stator slot 5, and cutout D4 in the middle of the stator slot 5.

[0024] The radial dimension L of the notch at the notch is as follows: the radial dimension of the notch A1 is larger than the notch C3, the radial dimension of the notch C3 is larger than the notch B2, and the midpoint of the circumferential length of the notch of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com