Battery locking mechanism for battery replacement of automobile

A locking mechanism and electric battery technology, applied in electric vehicles, charging stations, vehicle energy storage, etc., can solve problems such as low reliability, complex locking mechanism, high failure rate, etc., to ensure timely response and improve safety and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

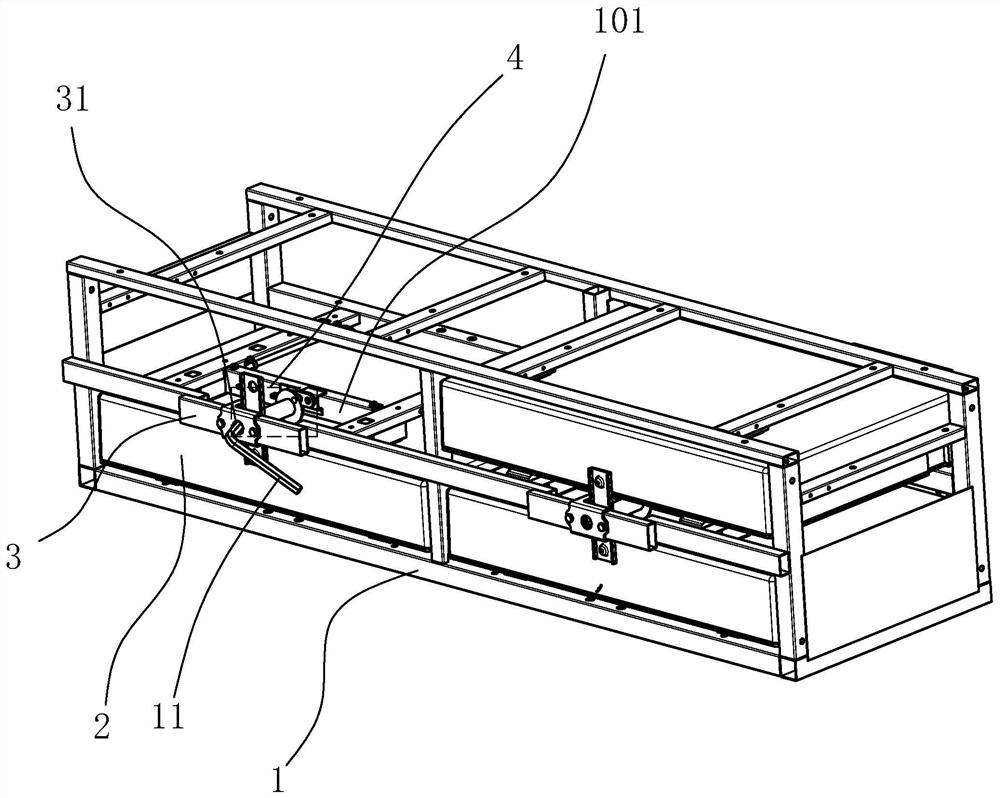

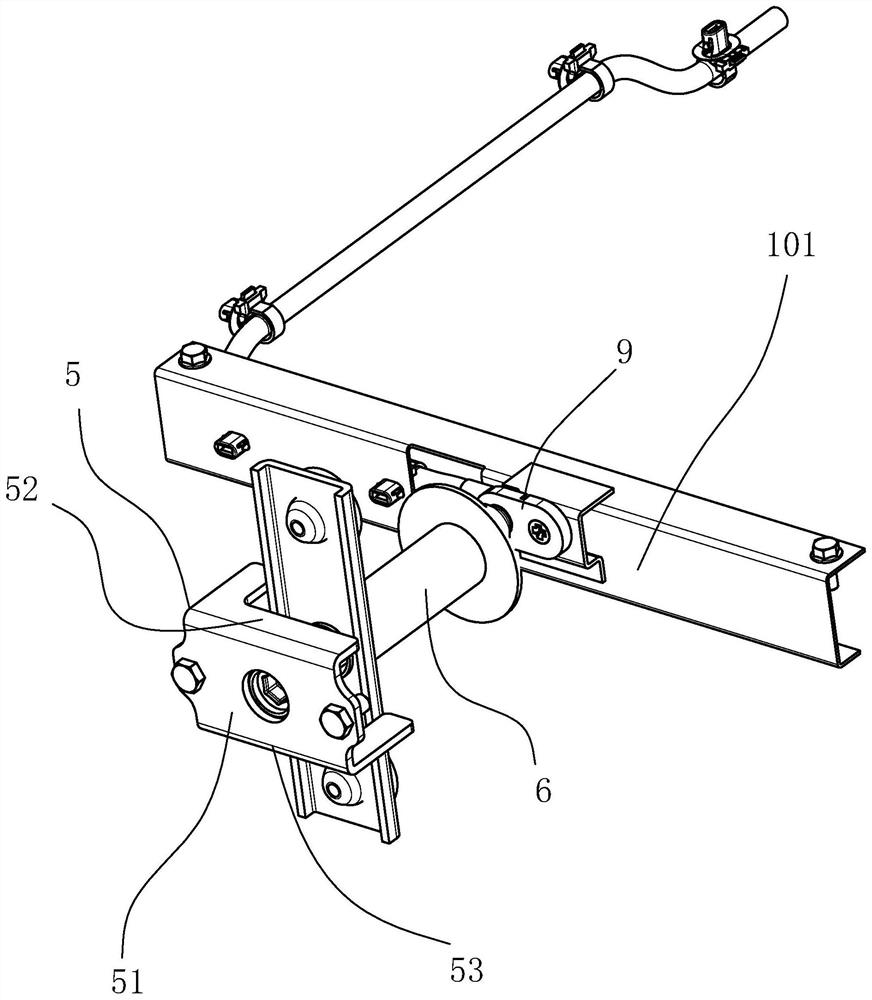

[0027] Such as figure 1 As shown, a battery locking mechanism for battery replacement in automobiles includes a base beam 101 arranged between battery frames 1, and a press-fit locking mechanism is provided on the front end of the base beam, and the press-fit locking mechanism includes a press-fit assembly 4 and the driving rod 11 arranged outside the pressing assembly, the driving rod can rotate and drive the pressing assembly to press the battery pack 2 toward the base beam. The base beam is installed on the car battery frame and can be installed by welding or screwing. The battery frame is a rectangular parallelepiped frame assembled by several beams. The base beam is arranged in the middle of the adjacent battery pack, and the width of the base beam is narrower than that of the battery frame, so as to prevent the base beam from exceeding the frame beam and interfering with the battery pack. The press-fit locking mechanism provided on the base beam can press-fit the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com