A kind of polysaccharide-based hydrotalcite nanocomposite tanning agent and its preparation method and application

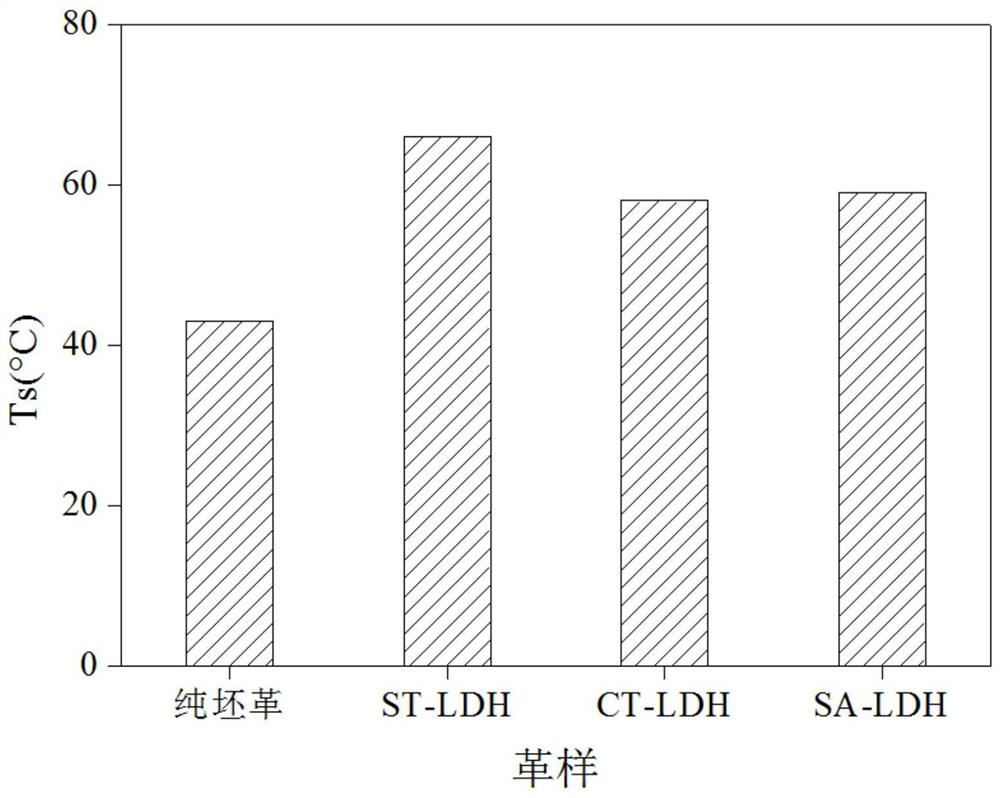

A technology of compound tanning agent and hydrotalcite, applied in the field of leather tanning, can solve the problems of uneven distribution, low tanning efficiency, low absorption rate of single metal tanning agent, etc., and achieve the effect of slowing down the binding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a starch-based hydrotalcite nanocomposite tanning agent, comprising the following steps:

[0036] S1: in parts by mass, mix 50 parts of starch and 100 parts of water uniformly to obtain an initial polysaccharide solution; add 0.05 part of ferrous sulfate to the initial polysaccharide solution under the condition that the water bath temperature is 70 degrees Celsius, and add 100 parts of 30% hydrogen peroxide after stirring The solution is subjected to oxidation reaction for 3 hours to obtain a pretreated polysaccharide polymer, and the pH value of the pretreated polysaccharide polymer is adjusted to 2 with a sodium hydroxide solution to obtain a polysaccharide polymer;

[0037] S2: Stir 80 parts of magnesium nitrate, 40 parts of aluminum nitrate, 40 parts of zirconium nitrate and 500 parts of deionized water to obtain a mixed salt solution, then drop the mixed salt solution into 300 parts of 2M anhydrous sodium carbonate solution to obtain a mixed...

Embodiment 2

[0040] A preparation method of a chitosan-based hydrotalcite nanocomposite tanning agent, comprising the following steps:

[0041] S1: in parts by mass, mix 70 parts of chitosan and 200 parts of water uniformly to obtain an initial polysaccharide solution; add 0.05 part of ferrous sulfate to the initial polysaccharide solution under the condition that the water bath temperature is 80°C, and add 200 parts of 30 % hydrogen peroxide solution is oxidized for 5 hours to obtain a pretreated polysaccharide polymer, and the pH value of the pretreated polysaccharide polymer is adjusted to 4 with sodium hydroxide solution to obtain a polysaccharide polymer;

[0042] S2: Stir 90 parts of magnesium chloride, 50 parts of aluminum chloride, 30 parts of tetravalent zirconium chloride and 500 parts of deionized water to obtain a mixed salt solution, and then drop the mixed salt solution into 400 parts of 1M anhydrous sodium carbonate solution, A mixed solution was obtained, the mixed solution...

Embodiment 3

[0045] A preparation method of a sodium alginate-based hydrotalcite nanocomposite tanning agent, comprising the following steps:

[0046] S1: in parts by mass, mix 100 parts of sodium alginate and 600 parts of water evenly to obtain an initial polysaccharide solution; add 0.05 parts of copper sulfate and 2 parts of ferrous sulfate to the initial polysaccharide solution under the condition that the water bath temperature is 75°C, and stir Then add 250 parts of 30% hydrogen peroxide solution to carry out oxidation reaction for 6 hours to obtain a pretreated polysaccharide polymer, and adjust the pH value of the pretreated polysaccharide polymer to 3 with sodium hydroxide solution to obtain a polysaccharide polymer;

[0047] S2: stir 100 parts of magnesium sulfate, 40 parts of aluminum sulfate, 50 parts of zirconium sulfate and 500 parts of deionized water to obtain a mixed salt solution, and then drop the mixed salt solution into 600 parts of 1.5M sodium carbonate aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com