Recycling method of nickel-cobalt-manganese ternary lithium battery

A nickel-cobalt-manganese ternary lithium and ternary lithium battery technology, which is applied in the recycling field of nickel-cobalt-manganese ternary lithium batteries, can solve the problem of uneven distribution of nickel-cobalt-manganese elements, poor electrochemical performance of positive electrode materials, and the inability of Al elements Evenly enter the interior of the material lattice to achieve the effect of slowing down the precipitation and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

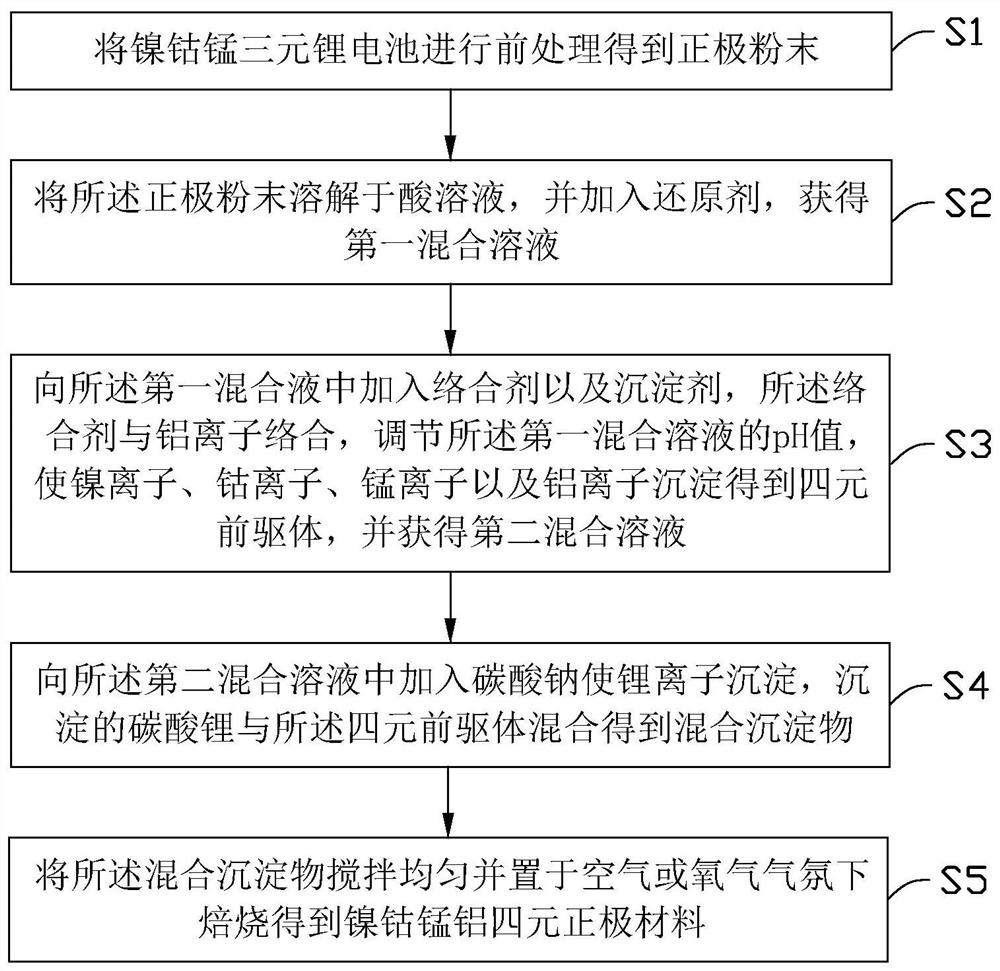

Method used

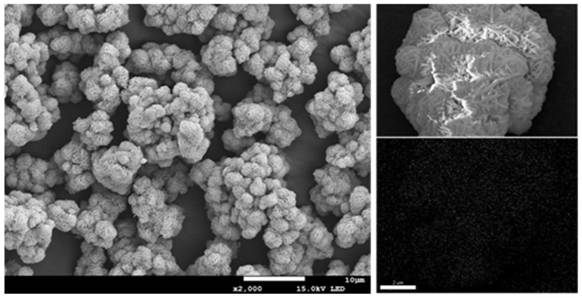

Image

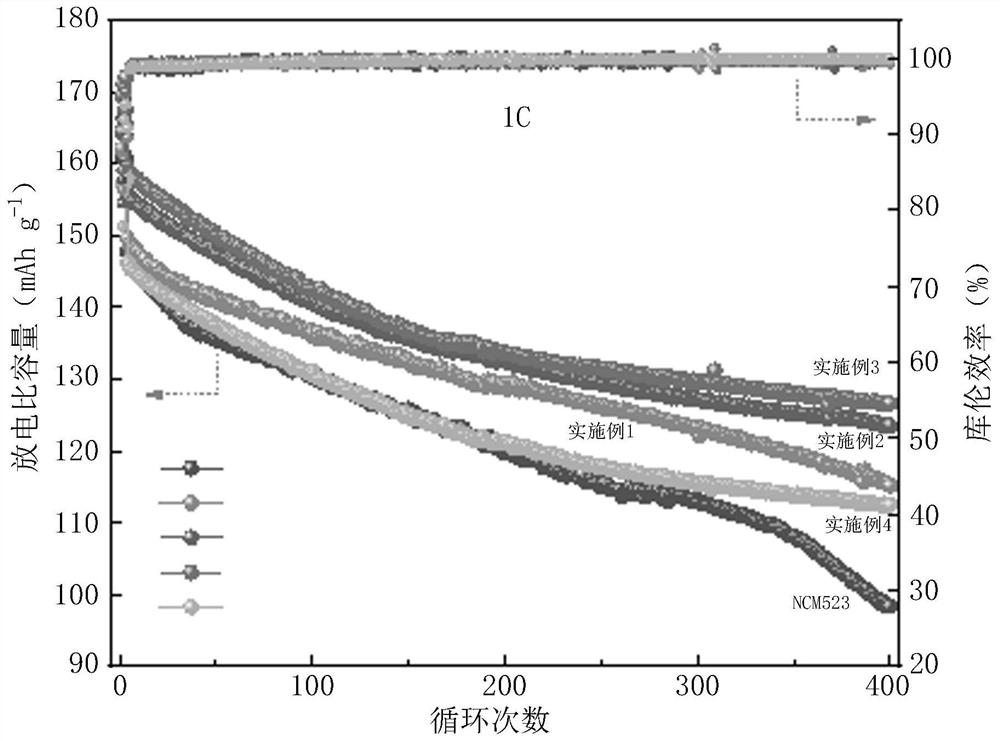

Examples

Embodiment 1

[0083] (1) After the waste nickel-watery three-membered lithium ion battery is fully discharged, the physical dismantling is performed, and the positive electrode sheet is obtained, and the positive electrode is broken, and the calcination temperature is 400 ° C, the calcination time is 3 hours, so that The active substance is separated from the aluminum foil. The screened was obtained from the waste positive electrode powder, and the powder was dissolved in a 1.5 mol / L sulfuric acid solution, and the starch was added to 6 to 8 g / L, the control temperature was 55 ° C, and the stirred leached for 30 minutes. After leaching, filter it to get Li + Ni 2+ , CO 2+ Mn 2+ Cu 2+ Al 3+ The first mixture of plasma.

[0084] (2) Add 3 times CU to the leaching liquid 2+ Moorer amount of sodium thiosulfate removes Cu 2+ After filtration, the purifying liquid is obtained.

[0085] (3) Determination of each metal ion ratio in the purifying liquid, then adding the corresponding sulfate, regula...

Embodiment 2

[0088](1) After the waste nickel-watery three-membered lithium ion battery is fully discharged, the physical dismantling is performed, and the positive electrode sheet is obtained, and the positive electrode is broken, and the calcination temperature is 400 ° C, the calcination time is 3 hours, so that The active substance is separated from the aluminum foil. The screened was obtained from the waste positive electrode powder, and the powder was dissolved in a 1.5 mol / L sulfuric acid solution, and the starch was added to 6 to 8 g / L, the control temperature was 55 ° C, and the stirred leached for 30 minutes. After leaching, filter it to get Li + Ni 2+ , CO 2+ Mn 2+ Cu 2+ Al 3+ The first mixture of plasma.

[0089] (2) Add 3 times CU to the leaching liquid 2+ Moorer amount of sodium thiosulfate removes Cu 2+ After filtration, the purifying liquid is obtained.

[0090] (3) Determination of each metal ion ratio in the purifying liquid, then adding the corresponding sulfate, regulat...

Embodiment 3

[0093] (1) After the waste nickel-watery three-membered lithium ion battery is fully discharged, the physical dismantling is performed, and the positive electrode sheet is obtained, and the positive electrode is broken, and the calcination temperature is 400 ° C, the calcination time is 3 hours, so that The active substance is separated from the aluminum foil. The screened was obtained from the waste positive electrode powder, and the powder was dissolved in a 1.5 mol / L sulfuric acid solution, and the starch was added to 6 to 8 g / L, the control temperature was 55 ° C, and the stirred leached for 30 minutes. After leaching, filter it to get Li + Ni 2+ , CO 2+ Mn 2+ Cu 2+ Al 3+ The first mixture of plasma.

[0094] (2) Add 3 times CU to the leaching liquid 2+ Moorer amount of sodium thiosulfate removes Cu 2+ After filtration, the purifying liquid is obtained.

[0095] (3) Determination of each metal ion ratio in the purifying liquid, then adding the corresponding sulfate, regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com