Universal transmission tool for processing crosshead pin of marine diesel engine

A technology for marine diesel engines and crosshead pins, which is applied to grinding drive devices, metal processing equipment, and parts of grinding machine tools, can solve the problems of various types of crosshead pin tooling and frequent clamping, etc. Safe and reliable performance, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention cannot be limited thereby.

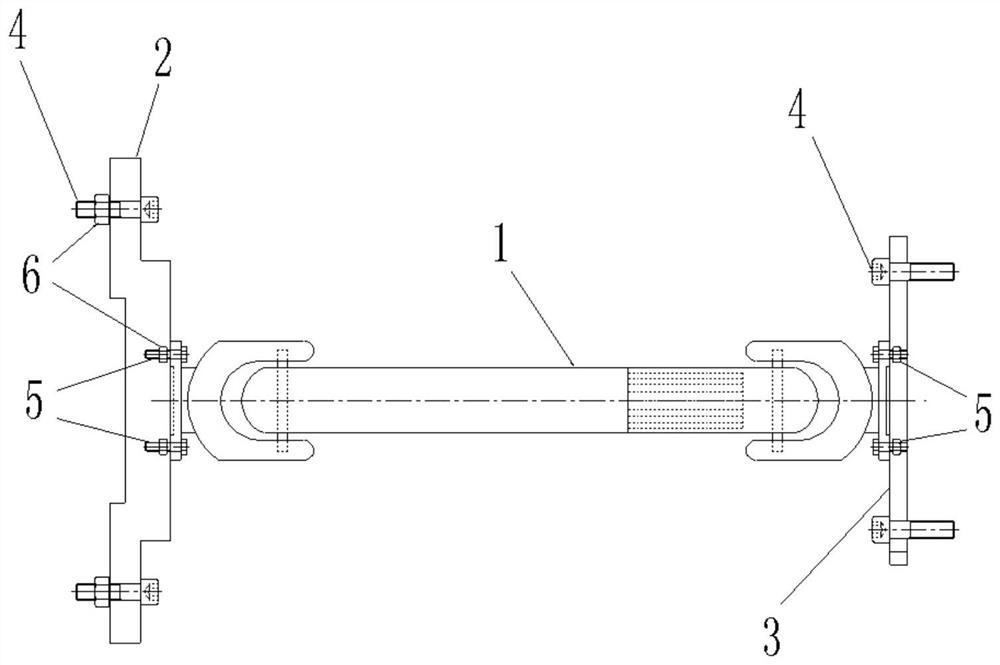

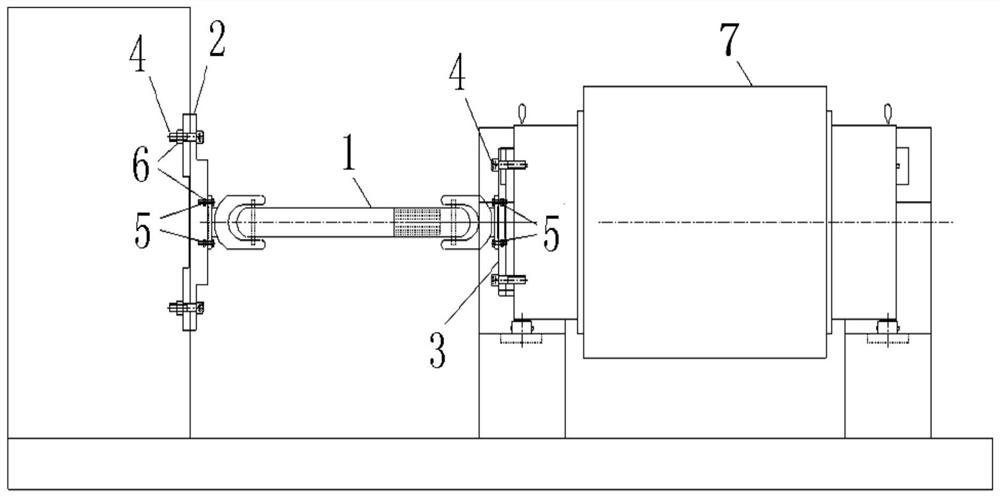

[0017] Such as figure 1 As shown, the general transmission tooling for machining crosshead pins of marine diesel engines is installed on the machine tool, including universal transmission rod 1, chuck connection plate 2, general transmission plate 3, hexagon socket head cap screws 4, bolts 5 and nuts 6 .

[0018] see figure 2 , the chuck connecting plate 2 is fixedly connected to the machine tool by means of hexagon socket head cap screws 4 and nuts 6 .

[0019] The universal transmission plate 3 is fixedly connected to the end face of the crosshead pin 7 through the hexagon socket head cap screw 4 and the nut 6, and the universal transmission plate 3 is suitable for various types of crosshead pins.

[0020] The universal transmission rod 1 is used to transmit the spatially inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com