Variable-thickness titanium alloy skin integrated forming method

A titanium alloy and variable thickness technology, which is applied in the field of integrated forming of titanium alloy skin with variable thickness, can solve the problems of material utilization rate less than 10%, low material utilization rate, low processing efficiency, etc., and achieve the improvement of material utilization rate, The effect of improving the product qualification rate and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

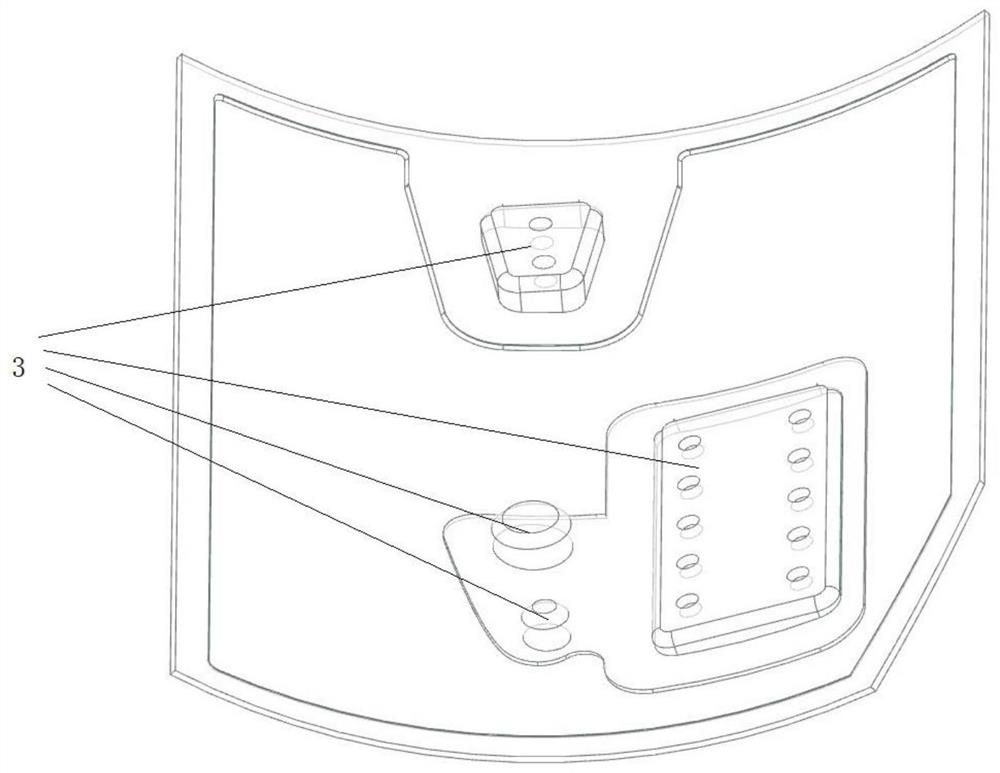

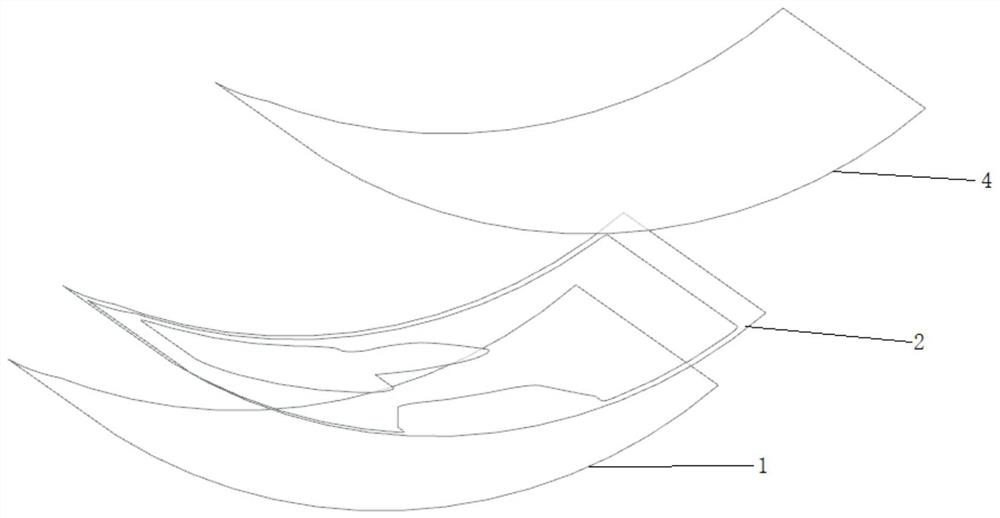

[0093] Design an aircraft transport cabin skin, which is a rectangular arc panel with one corner missing, Figure 4 is a schematic diagram of the skinned plane unfolding, figure 1 It is a schematic diagram of the variable-thickness titanium alloy skin after forming.

[0094]Step 1: The skin material is TA15, and the skin is a curved panel. After unfolding, it becomes a rectangle with one corner missing, with a length of 470mm×width of 400mm. The edge is designed to be 3mm thick for riveting with the skeleton, and the thickness of the skin center is 1mm. In addition, according to design requirements, four pieces of equipment need to be installed on the inner skin, and four bosses are welded or riveted at corresponding positions.

[0095] The installation boss A is a cuboid: 170mm (length) × 80mm (width) × 10mm (height);

[0096] The installation boss B is an isosceles trapezoid: 40mm (waist) × 50mm (long side) × 35mm (short side) × 15mm (height);

[0097] The mounting boss C...

Embodiment 2

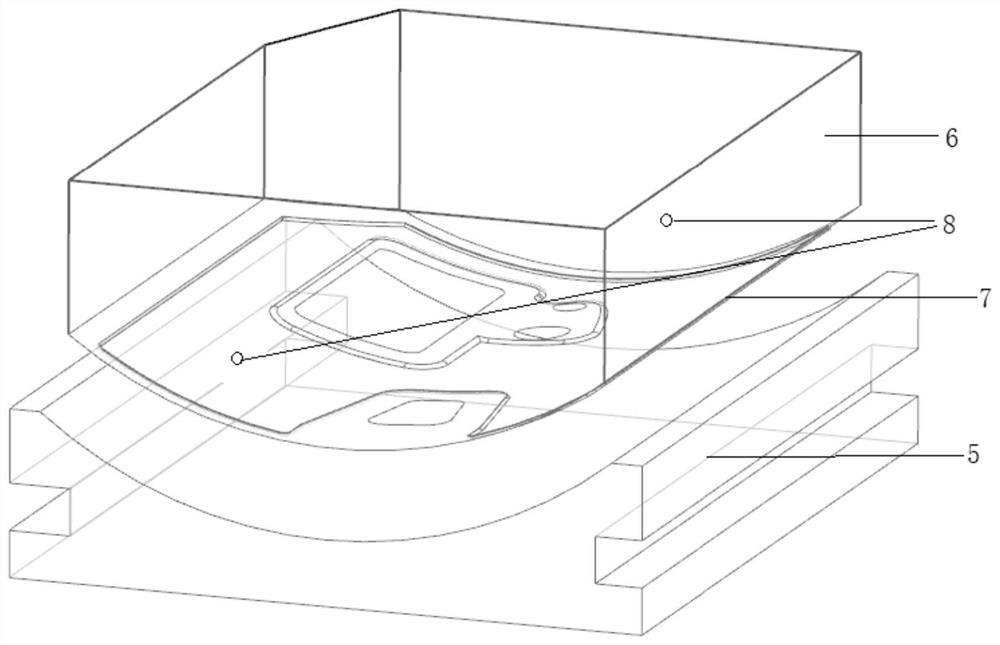

[0115] Figure 7 It is a finished drawing of the skin of a certain part of an aircraft shell, and the following is the specific production and implementation process.

[0116] Step 1: The skin material is TA15, the skin is a rectangular arc panel, the length is 380×320mm, the edge is designed to be 3mm thick for riveting with the skeleton, and the thickness of the skin center is 2mm. According to the design requirements, there is a door-shaped convex groove on the skin, and the size is: (70mm+200mm+50mm) (length)×40mm (width)×30mm (depth). In addition, two pieces of equipment need to be installed on the inner skin, and two bosses are welded or riveted at corresponding positions.

[0117] The mounting boss A is a cylinder: 60mm (diameter) × 40mm (height);

[0118] The installation boss B is a short side of a cuboid + two circumscribed half cylinders: 40mm (length) × 20mm (width) × 20mm (height).

[0119] Step 2: Design and manufacture the outer skin 1 with a thickness of 1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com