A grounding elastic body and electronic equipment

A technology of electronic equipment and elastic body, which is applied in the direction of electrical components, magnetic/electric field shielding, and protection against damage caused by electrostatic discharge. , improve the service life and ensure the effect of rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

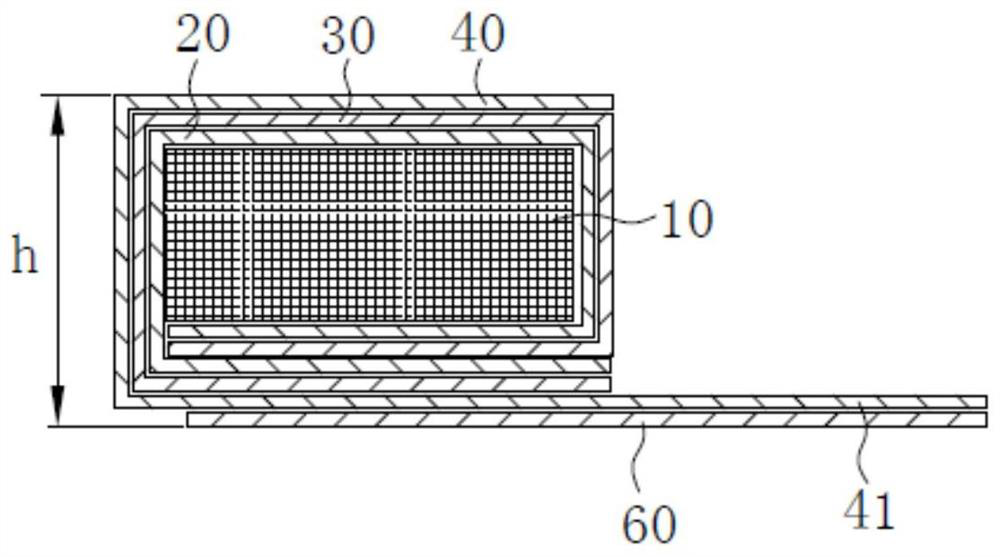

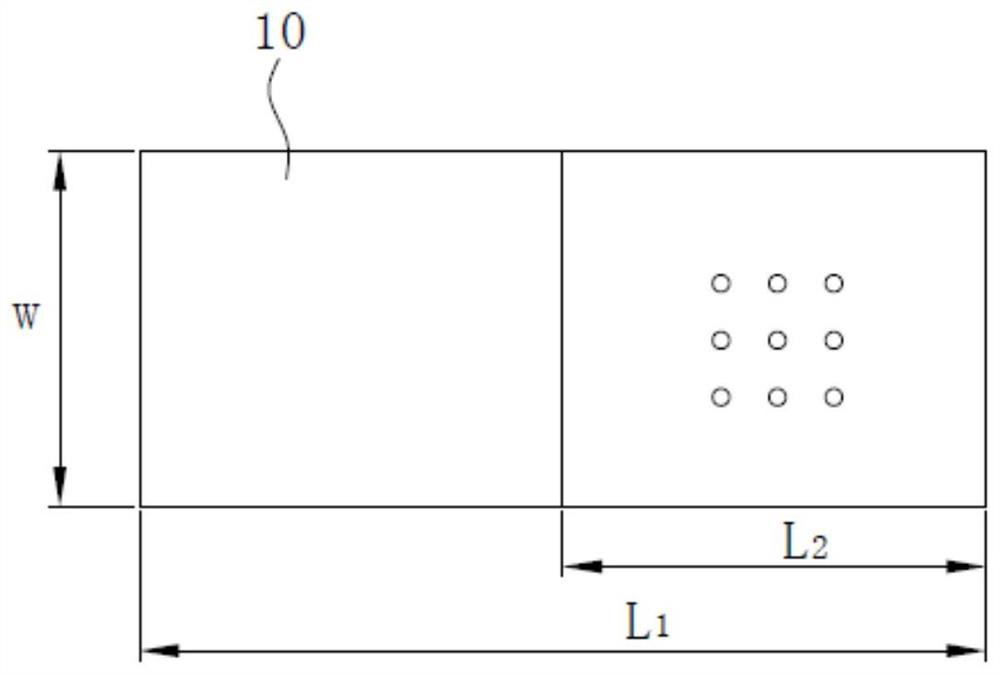

[0072] Such as figure 1 , 2 As shown, the grounding elastic body provided in this embodiment includes: an elastic core 10, a PET double-sided adhesive layer 20, a PI film 30, a conductive layer 40 and an insulating non-substrate adhesive layer 60, and the elastic core 10 adopts polyurethane foam Cotton, the conductive layer 40 is copper foil with gold plating on the outer surface; the overall length of the grounding elastic body is 6 mm, the length of the welding part is 2.6 mm, and the overall width of the grounding elastic body is 2.5 mm. In the natural state, the elastic core is 10 mm The overall height is 0.76mm, the thickness of the PI film 30 is 0.015mm, the thickness of the PET double-sided tape 20 is 0.01mm, the thickness of the conductive layer 40 is 0.03mm, and the thickness of the insulating non-substrate adhesive layer 60 is 0.01mm.

Embodiment 2

[0074] Such as image 3 As shown, the grounding elastic body provided by this embodiment differs from that of Embodiment 1 only in that a metal reinforcing plate 50 is bonded to the upper surface of the welding part 40, and the metal reinforcing plate 50 is provided with a PU layer on the upper surface. Copper foil, and the thickness of the metal reinforcing plate 50 is 0.018mm; other features are completely the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com