Superfine electroluminescent fiber and preparation method and application thereof

An electroluminescent fiber and electroluminescent layer technology, applied in the field of textile and chemical fibers, can solve the problems of thick and hard luminescent materials, poor weavable performance, and limited use scenarios, and achieve easy weaving, good friction resistance, and high application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

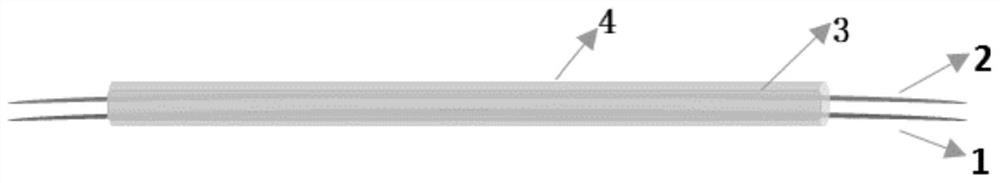

Method used

Image

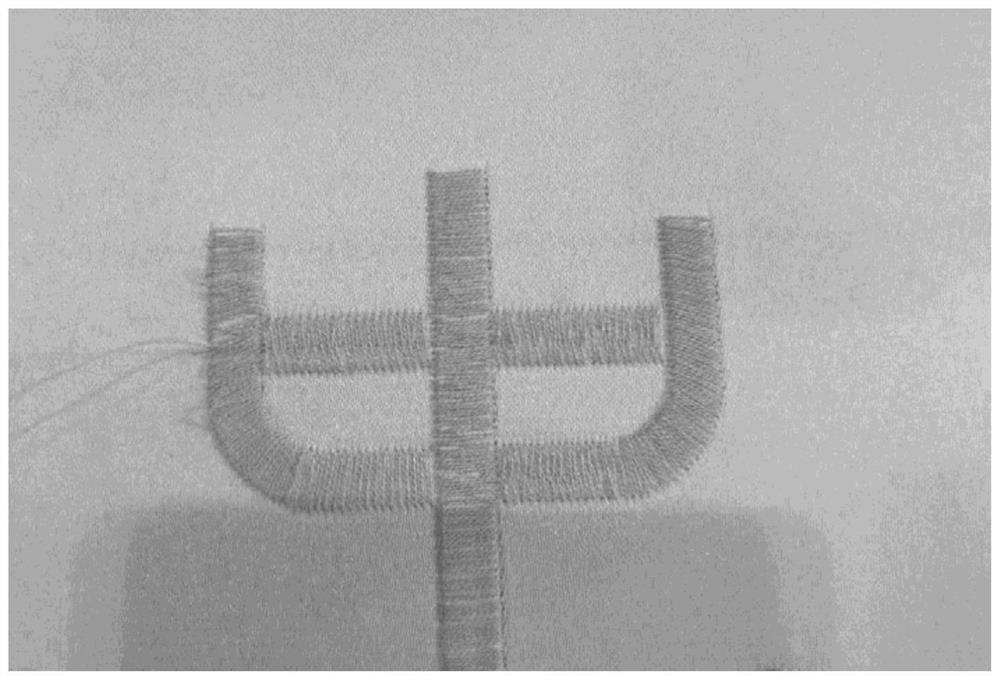

Examples

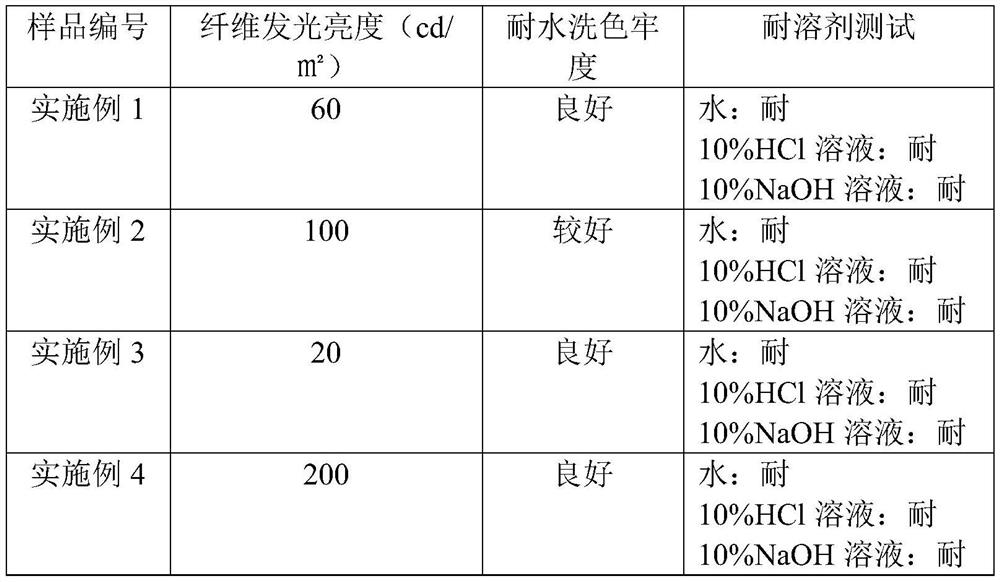

Embodiment 1

[0047] The first step: at room temperature 25 ℃, 50g SiO 2 : Add Ge luminescent powder (diameter 10μm) into 30g ethanol solvent, then add 19.5g polyvinyl alcohol adhesive, 0.5g sodium dodecylbenzenesulfonate surfactant and other additives, stir magnetically for 30min, and the stirring speed is 300rpm , to obtain uniformly dispersed luminescent paste.

[0048] Step 2: Turn on the dip coating device, uniformly coat the luminescent slurry on the surface of the copper wire fiber (100 μm in diameter) at a speed of 10 m / min, then dry it online at 100 ° C, and finally collect and wind it on a bobbin.

[0049] Step 3: Turn on the external electrode loading device, and incorporate copper wire fibers (30 μm in diameter) into the fibers in a winding manner.

[0050] Step 4: Turn on the packaging device, evenly coat the 50wt% water-based epoxy resin solution on the surface of the fiber at a speed of 8m / min, then dry it online at 100°C, and finally collect and wind it on the bobbin. The t...

Embodiment 2

[0053] Step 1: Add 40g CaS luminescent powder (diameter 30μm) to 30g acetone solvent at room temperature 25°C, then add 29 polyurethane adhesive, 1.0g cetyltrimethylammonium chloride surfactant and other additives , and magnetically stirred for 20 minutes at a stirring speed of 500 rpm to obtain a uniformly dispersed luminescent slurry.

[0054] Step 2: Turn on the dip coating device, evenly coat the luminescent slurry on the surface of the graphene conductive fiber (200 μm in diameter) at a speed of 15 m / min, then dry it online at 150 ° C, and finally collect and wind it on a bobbin.

[0055] Step 3: Turn on the external electrode loading device, coat the conductive silver paste on the surface of the luminescent active layer at a speed of 5m / min, and then dry it online at 100°C.

[0056] Step 4: Turn on the packaging device, apply 30wt% polyvinylidene fluoride resin solution evenly on the surface of the fiber at a speed of 10m / min, then dry it online at 150°C, and finally col...

Embodiment 3

[0059] Step 1: Add 30g GaN luminescent powder (diameter 10μm) into 30g deionized water at room temperature 25°C, then add 39.6g polyurethane adhesive, 0.4g Tween 80 surfactant, stir magnetically for 30min at a stirring speed of 400rpm, A uniformly dispersed luminescent slurry is obtained.

[0060] Step 2: Turn on the dip coating device, evenly coat the luminescent slurry on the surface of the carbon black conductive fiber (250 μm in diameter) at a speed of 8 m / min, then dry it online at 120 ° C, and finally collect and wind it on a bobbin.

[0061] Step 3: Turn on the external electrode loading device, and incorporate carbon nanotube fiber multifilaments (20 μm in diameter) into the fibers in a parallel arrangement.

[0062] Step 4: Turn on the packaging device, apply 40wt% acrylic resin solution evenly on the surface of the fiber at a speed of 5m / min, then dry it online at 80°C, and finally collect and wind it on the bobbin. The thickness of the packaging layer is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com