Horizontal die splitting mechanical horizontal forging machine

A technology of horizontal split die and flat forging machine, which is used in forging/pressing/hammering machinery, swaging presses, upsetting presses, etc., which can solve the problems of reduced equipment reliability, large impact force, and poor operating conditions. , to achieve the effect of improving stability, large transmission torque and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

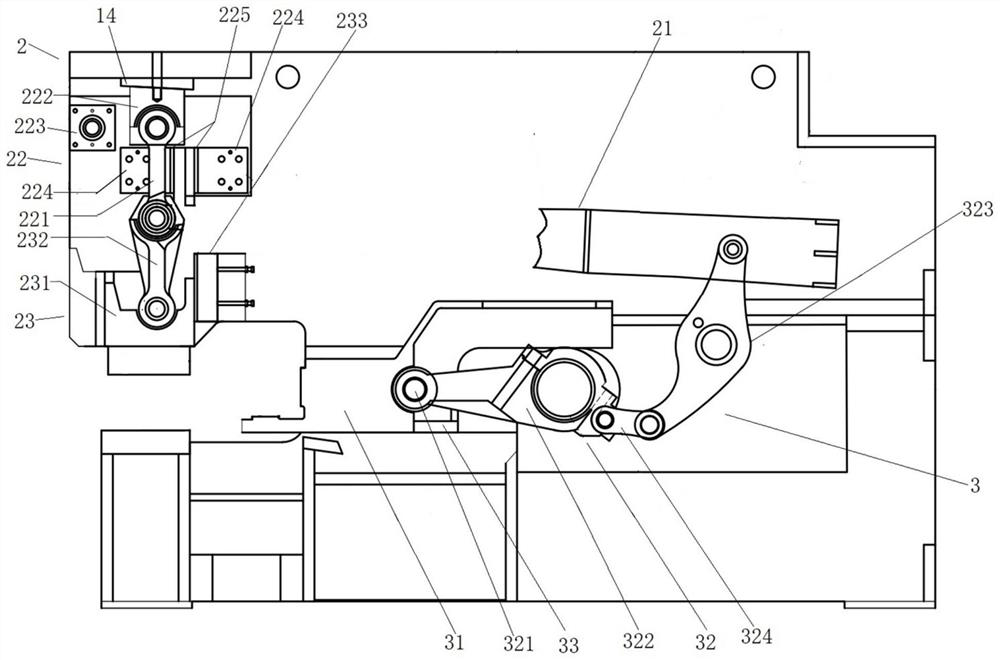

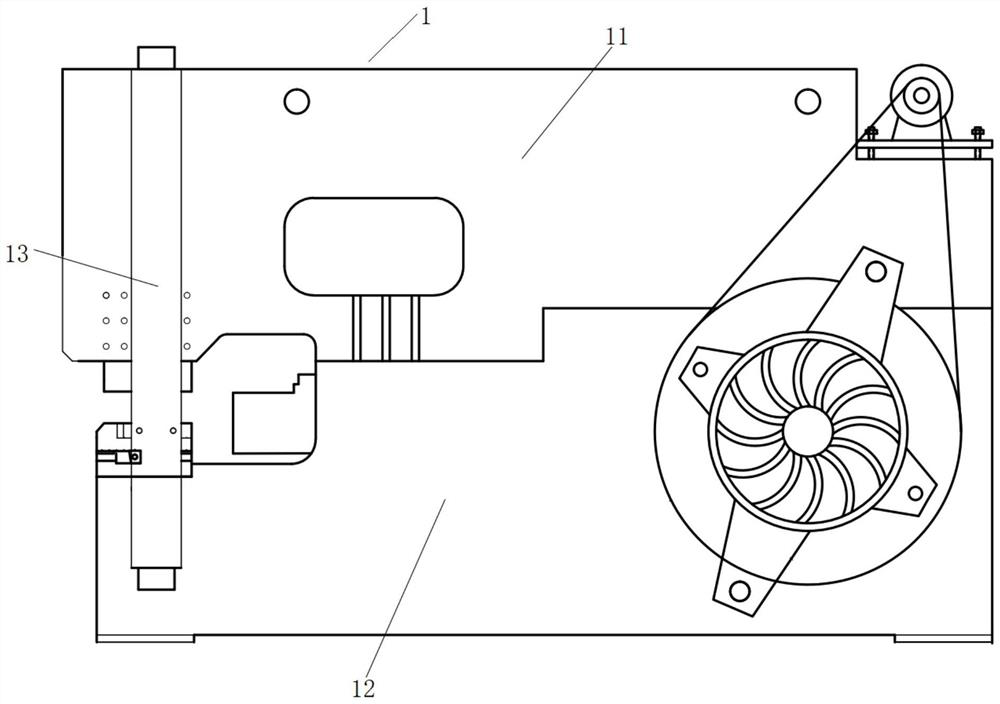

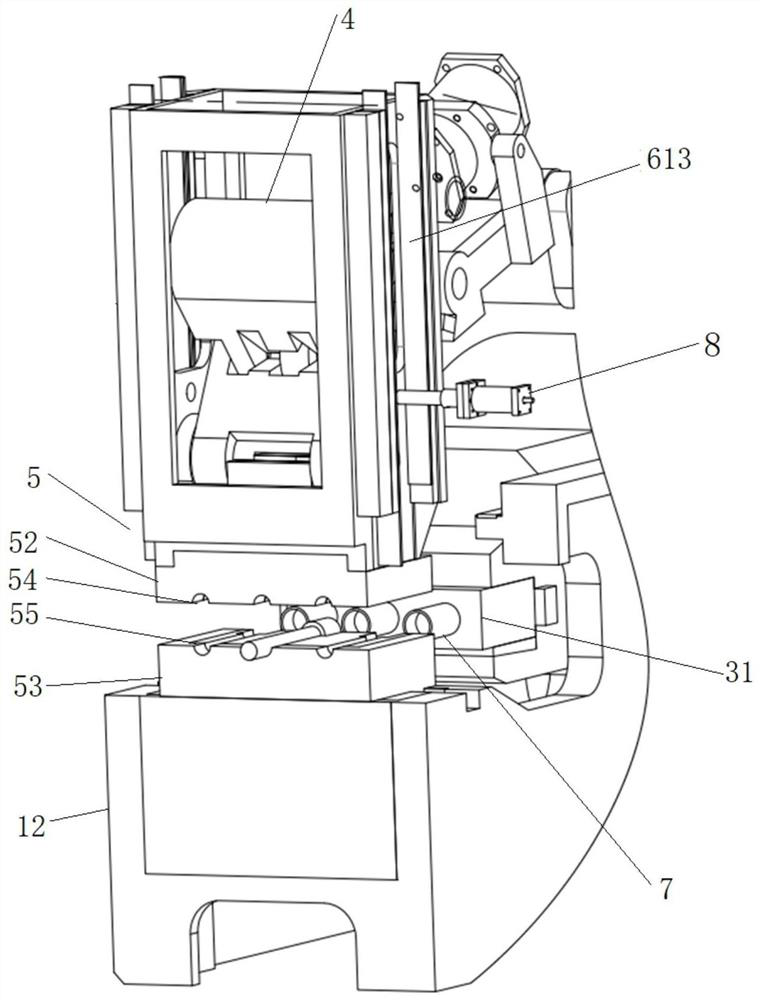

[0053] Such as Figure 1-8 Shown: a horizontal die splitting mechanical flat forging machine, including a fuselage 1, and also includes a clamping device 2 arranged in the vertical direction of the fuselage 1 and a die device 3 in the horizontal direction; the fuselage 1 includes an upper The fuselage 11 and the lower fuselage 12, the upper fuselage 11 and the lower fuselage 12 are fixedly connected at the joint surface of the waist of the whole machine by bolts;

[0054] The clamping device 2 in the vertical direction includes a pull rod 21, an upper connection assembly 22 and a lower connection assembly 23;

[0055] The upper connection assembly 22 includes an upper connection plate 221, a connection seat 222, a support seat 223 and a clamping upper guide rail 224, the upper connection plate 221 is hinged to the pull rod 21, and the support seat 223 is fixed to the upper body 11, so The connection seat 222 is fixedly connected with the support seat 223 to ensure the fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com