Continuous production forming equipment for zipper teeth

A technology of forming equipment and zipper teeth, applied in the field of zippers, can solve the problems of inapplicability to the production needs of small and medium-sized enterprises, high loss, short service life of cutting tools, etc., so as to improve the quality of zipper products, improve the service life, and ensure continuous operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

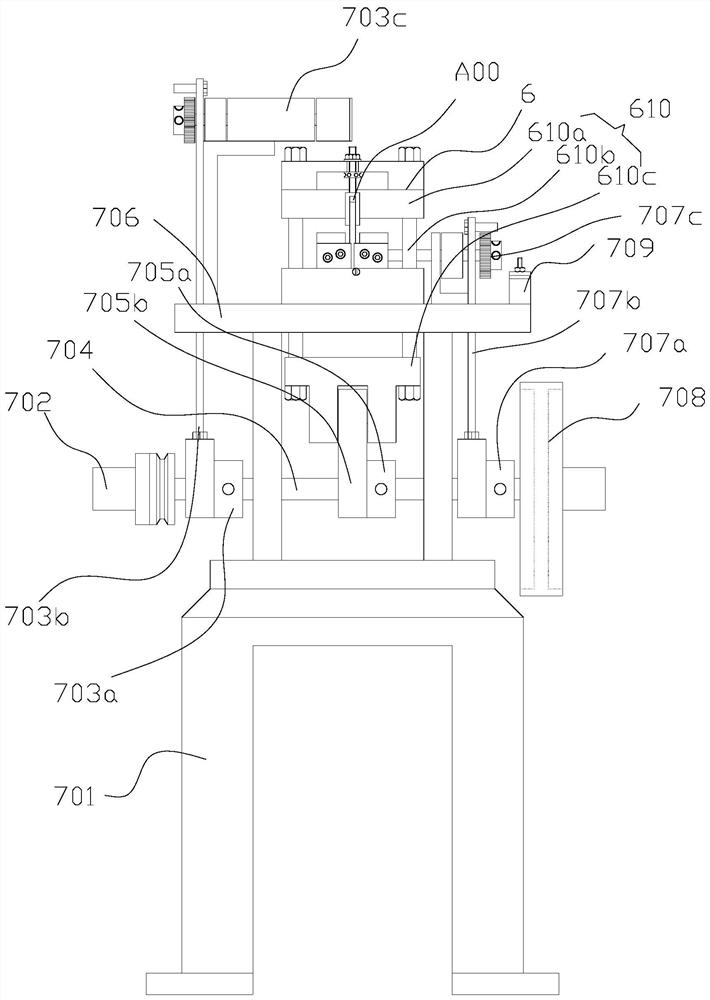

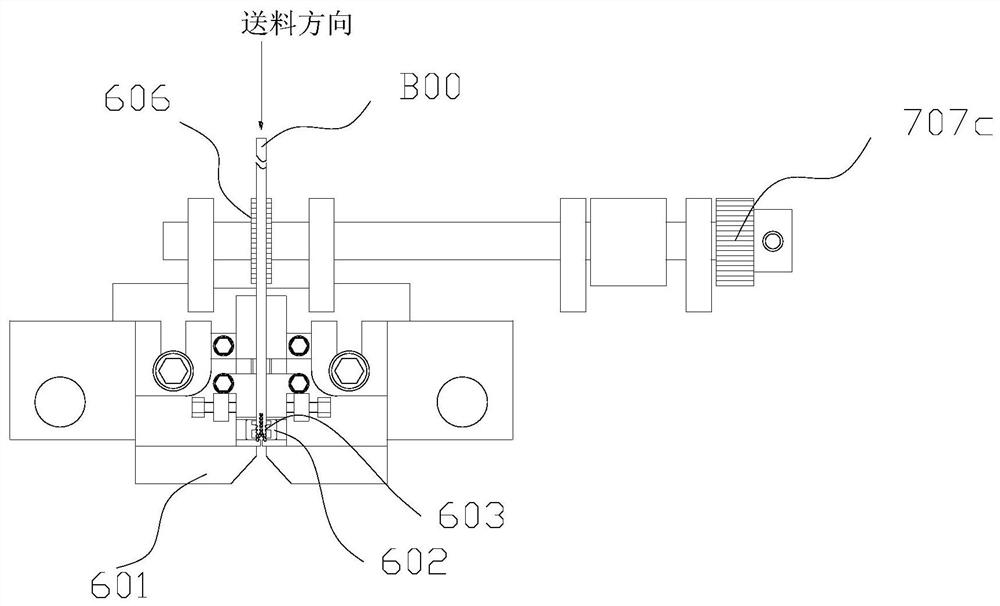

[0077] Such as Figure 1-Figure 10 and Figure 14 , Figure 15 As shown, a zipper element continuous production molding equipment is used for punching and forming the zipper element B01 from the floss B00 and pressing it on the cloth tape, including a frame 701 and a processing platform 706 set on the frame 701 , stamping device 6 and conveying structure,

[0078] The processing platform 706 is located on the upper part of the frame 701, and is fixedly connected with the frame 701, and the punching device 6 is arranged on the processing platform 706;

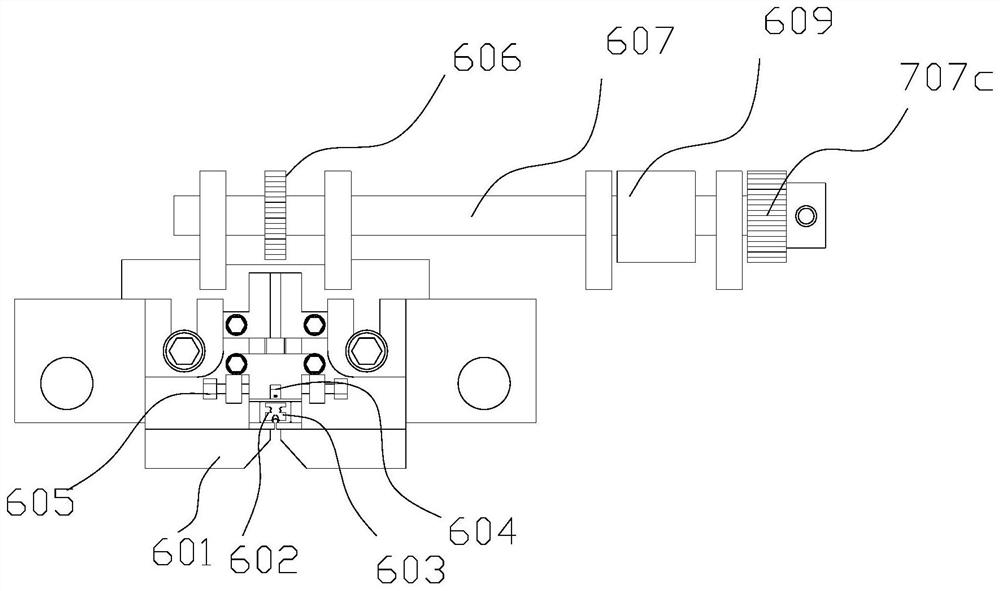

[0079] The stamping device 6 includes an upper die, a lower die 602, a convergent hammer 601 and a punch / die punch 604,

[0080] The upper mold includes a tool holder 608 and a cutting tool arranged from top to bottom, and the cutting tool includes a tool body A00 in a linear profile, and the upper end of the tool body A00 is provided with a The fixed clamping part 1 is provided with a punching surface 2 at the lower end, an...

Embodiment 2

[0125] One of the embodiments of the present invention, such as Figure 1-Figure 4 and Figure 11-Figure 15 As shown, the main technical solutions of this embodiment and Embodiment 1, the features that are not explained in this embodiment, use the explanation in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0126] The cutting tool is a combination tool, including a left tool unit 11, a right tool unit 12 and an alloy sheet 14. The left tool unit 11 is fixedly connected to the right tool unit 12, and combined to form the tool body A00. The bottom of the cutter body A00 is provided with an alloy sheet 14, the alloy sheet 14 is fastened and connected with the cutter body A00, and the lower end surface of the alloy sheet 14 forms the punching surface 2; the thickness of the alloy sheet 14 is 1 mm to 3 mm; in this embodiment, the thickness of the alloy sheet 14 is preferably 1.5 mm;

[0127] It should be noted that the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com