Continuous treatment method of swill oil

A treatment method, swill oil technology, applied in biochemical equipment and methods, hydrolytic enzymes, enzymes, etc., can solve the problems of low quality stability of fatty acids, fluctuations in reaction yield, poor production continuity, etc., to shorten the enzymatic hydrolysis reaction Time, improved stability, and reduced volatility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

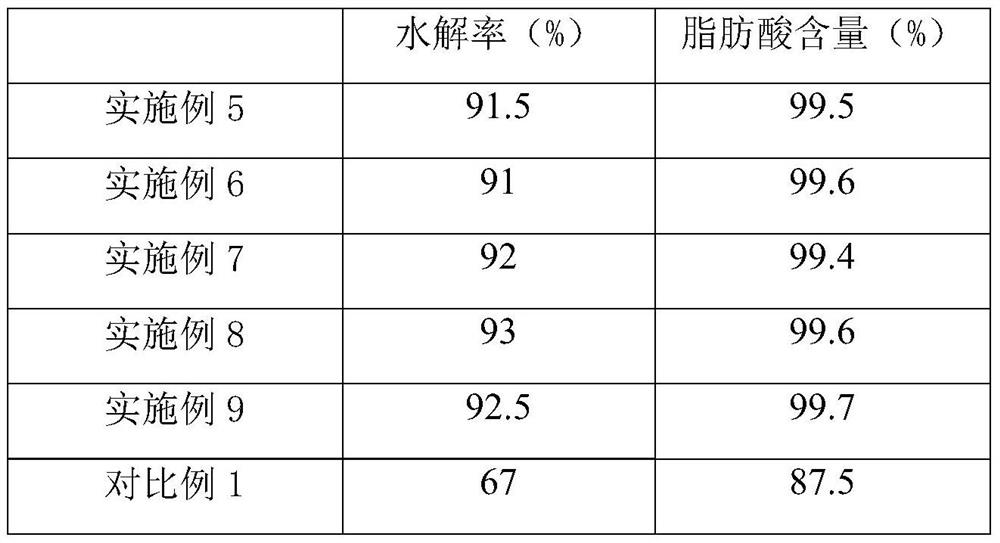

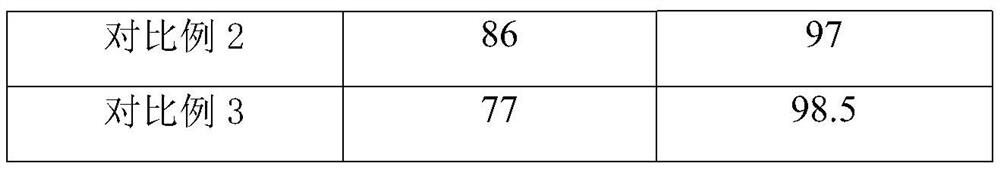

Examples

Embodiment 1

[0026] This embodiment provides a kind of Candida antarctica lipase A treated with acetonitrile, and its preparation method comprises the following steps: adding acetonitrile to Candida antarctica lipase A, adding 1.0mL per 100mg of Candida antarctica lipase A After fully mixing at 25° C. for 1 hour, the acetonitrile was removed by vacuum pump filtration, and dried with nitrogen to obtain acetonitrile-treated Candida antarctica lipase A.

Embodiment 2

[0028] This embodiment provides a kind of Candida antarctica lipase A treated with acetonitrile, and its preparation method comprises the following steps: adding acetonitrile to Candida antarctica lipase A, adding 1.5mL of Acetonitrile, after being fully mixed at 20°C for 2 hours, the acetonitrile was removed by vacuum pump filtration, and dried with nitrogen to obtain the acetonitrile-treated Candida antarctica lipase A.

Embodiment 3

[0030] This embodiment provides a kind of Candida antarctica lipase A treated with acetonitrile, and its preparation method comprises the following steps: adding acetonitrile to Candida antarctica lipase A, adding 1.3mL per 100mg of Candida antarctica lipase A After fully mixing at 21° C. for 1.5 hours, the acetonitrile was removed by vacuum pump filtration and dried with nitrogen to obtain acetonitrile-treated Candida antarctica lipase A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com