Method for connecting high-entropy ceramic and metal

A connection method, high-entropy alloy technology, applied in the field of welding, can solve the problems of reduced joint strength, difficult compatibility, and large residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A welding method for high-entropy ceramics and metals, comprising the steps of:

[0061] (1), adopt wire cutting to process (TaZrNbHfTi)C high-entropy ceramics into a diameter φ 15mm, a cylindrical sample with a height of 6mm, and use 600#, 800#, 1200#, 2000# diamond grinding discs to polish the surface to be welded successively, Then place it in a vibrating polishing machine, use aluminum oxide and silica gel solutions for rough polishing and fine polishing respectively until there are no scratches on the surface, then clean with alcohol under the action of ultrasonic waves, and finally dry it;

[0062] (2) To prepare TaZrNbHfTi refractory high-entropy alloy, according to the atomic ratio of each element of TaZrNbHfTi refractory high-entropy alloy 1:1:1:1:1, the metal raw material particles (purity > 99.9%) are proportioned and weighed; then Put the raw material into the electric arc melting furnace, and under the protection of high-purity argon, melt it repeatedly at ...

Embodiment 2

[0071] A high-entropy ceramic and metal welding method in this embodiment, the experimental steps are repeated in Example 1, the only difference is that "in step 5, the diffusion welding temperature is adjusted from 1650 ° C to 1700 ° C", other conditions and examples 1, a structure in which (TaZrNbHfTi)C high-entropy ceramics and Ti2AlNb alloys are connected by vacuum diffusion welding is finally obtained with TaZrNbHfTi refractory high-entropy alloy as the intermediate layer.

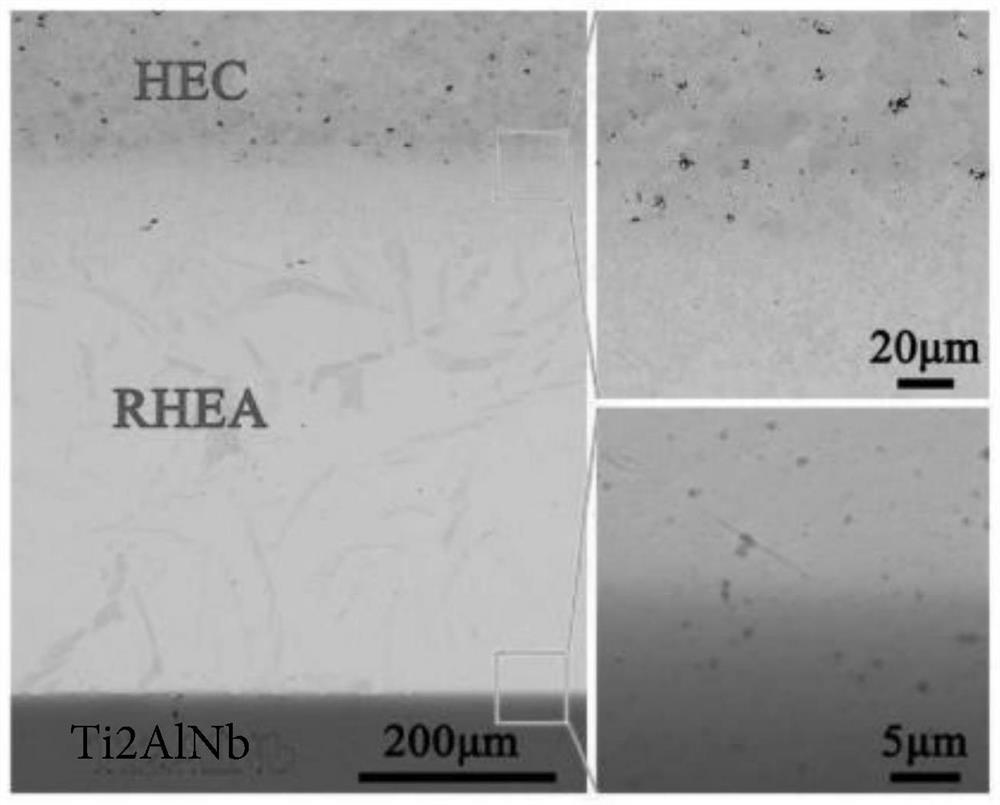

[0072] see figure 2 , is the interfacial micrograph of the connection between (TaZrNbHfTi)C high-entropy ceramics and Ti2AlNb alloy using TaZrNbHfTi refractory high-entropy alloy as the intermediate layer in Example 2, and adopting vacuum diffusion welding. Depend on figure 2 It can be seen that there are no obvious defects such as cracks and holes in the weak part of the welded joint, that is, the welding interface of (TaZrNbHfTi)C high-entropy ceramics and TaZrNbHfTi refractory high-entropy alloy...

Embodiment 3

[0074] A welding method for high-entropy ceramics and metals in this embodiment, the experimental steps are repeated in Example 1, the difference is only in "in step 5, the diffusion welding temperature is adjusted from 1650°C to 1750°C", other conditions and examples 1, a structure in which (TaZrNbHfTi)C high-entropy ceramics and Ti2AlNb alloys are connected by vacuum diffusion welding is finally obtained with TaZrNbHfTi refractory high-entropy alloy as the intermediate layer.

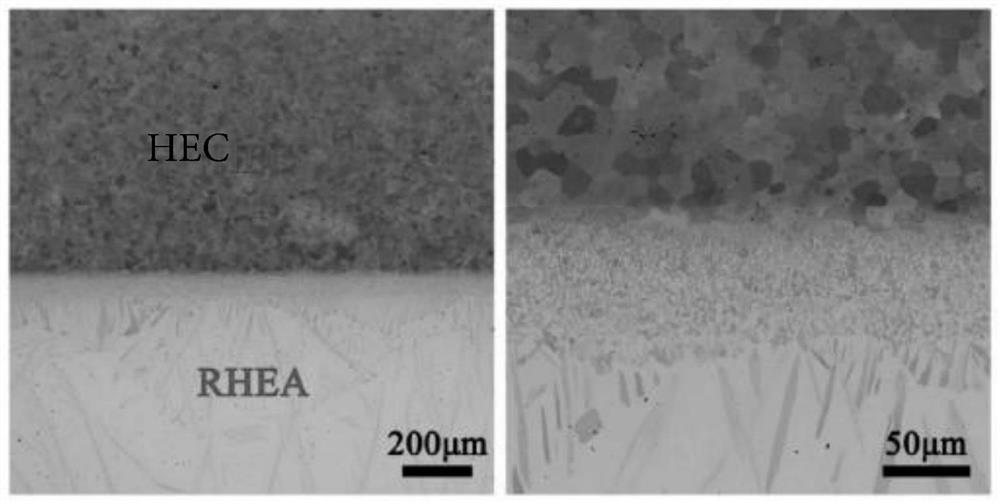

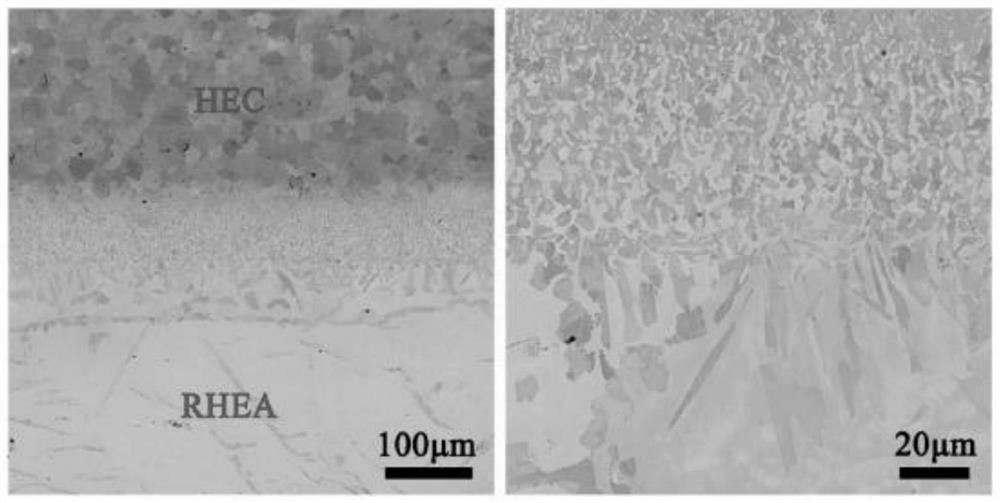

[0075] see image 3 , is adopting TaZrNbHfTi refractory high-entropy alloy as intermediate layer in embodiment 3, adopts vacuum diffusion welding to realize (TaZrNbHfTi)C high-entropy ceramics and Ti2AlNb alloy interfacial micrographs connected, by image 3It can be seen that there are no obvious defects such as cracks and holes in the weak part of the welded joint, that is, the welding interface of (TaZrNbHfTi)C high-entropy ceramics and TaZrNbHfTi refractory high-entropy alloy, and the microstructur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com