Gypsum-based dry-mixed mortar and preparation method thereof

A technology of gypsum and sand mixing, applied in the direction of additive processing, can solve the problems of poor performance of gypsum products, prone to frost, influence, etc., to improve durability and construction performance, improve crack resistance, and improve coating rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

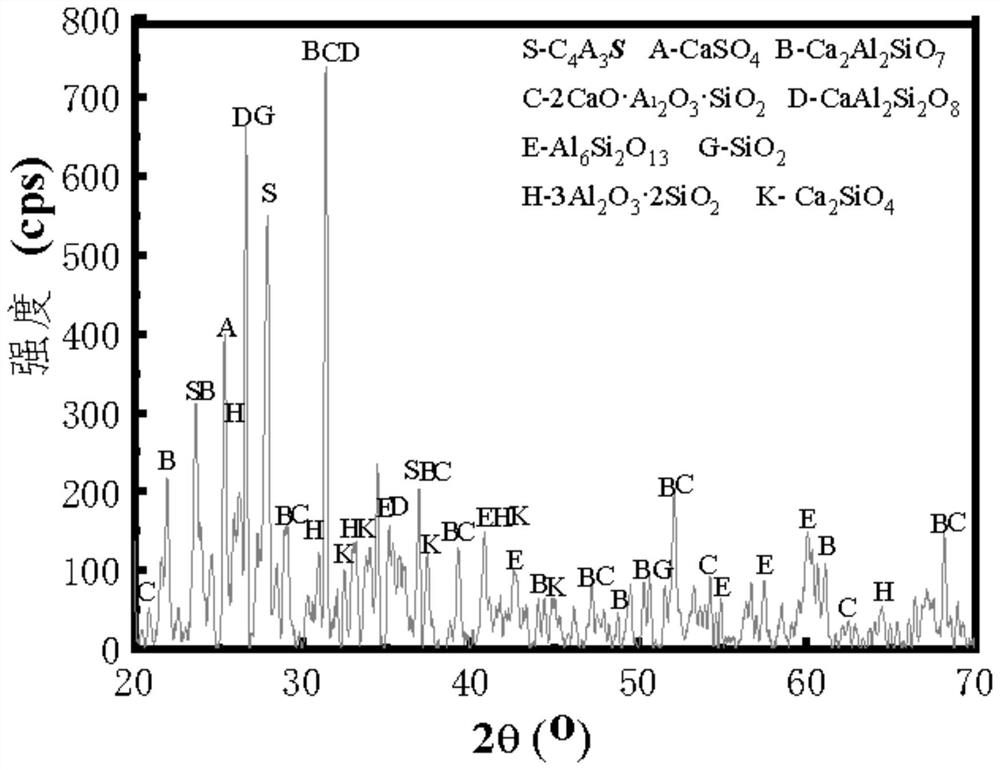

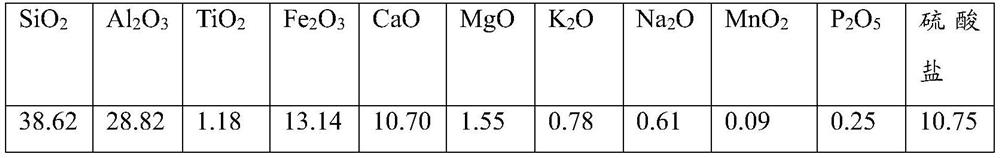

[0059] (1) Mix 100kg of sulfur-containing coal and 1.74kg of calcium carbonate uniformly to make briquettes, and to form coal ash after fully burning at 1200°C. The main chemical components are determined as follows:

[0060]

[0061] Pulverize the coal ash to 80 mesh.

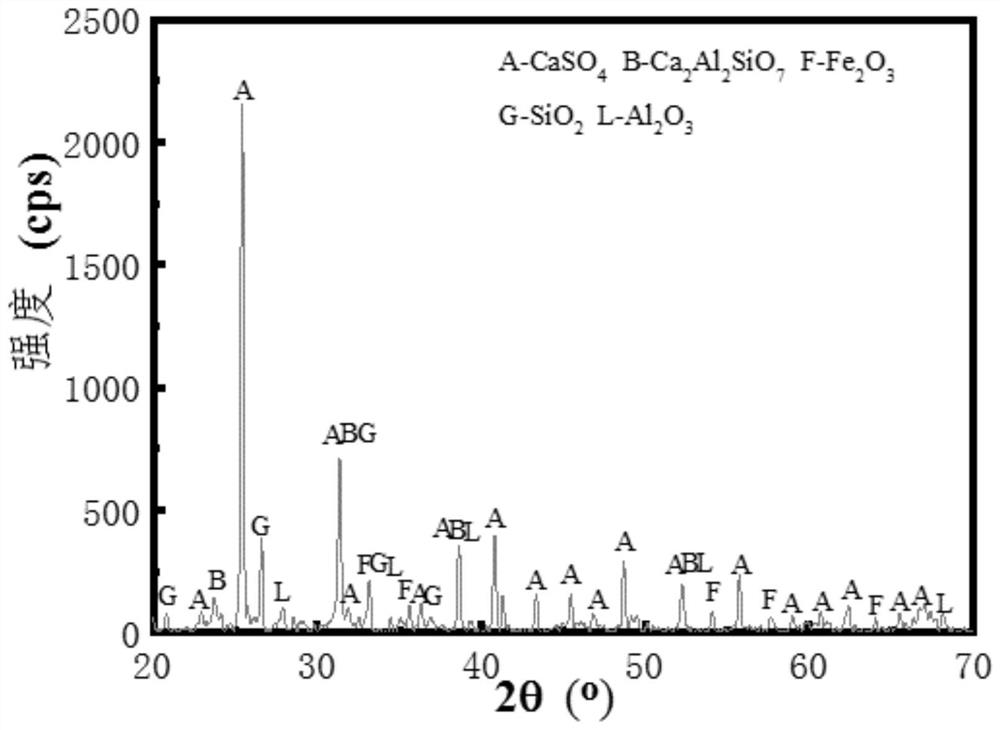

[0062] (2) Calcining low-quality desulfurized gypsum to prepare low-quality gypsum clinker (the prepared clinker is β-type hemihydrate gypsum), and the dihydrate gypsum content (DH) in the aged low-quality desulfurized clinker is 1.6wt.%. , anhydrous gypsum (AⅢ) is 1.3wt.%; Grinding, sealing for subsequent use, obtaining particle size is 200 orders, and D50 is the low-quality gypsum clinker of 40 μm to 50 μm;

[0063] (3) 100kg of low-quality gypsum clinker powder prepared in step (2), 0.5kg of zeolite powder and 10kg of prepared coal ash slag were mixed uniformly to obtain mixture 1;

[0064] (4) Test the standard consistency water consumption of the mixed powder (the mixture obtained by mixing 100kg of l...

Embodiment 2

[0069] The difference between embodiment 2 and embodiment 1 lies in step (3). Step (3): 100kg of gypsum powder prepared in step (1), 0.5kg of zeolite powder and 15kg of prepared coal ash are mixed evenly;

Embodiment 3

[0071] The difference between embodiment 2 and embodiment 1 lies in step (3). Step (3): 100kg of gypsum powder prepared in step (1), 0.5kg of zeolite powder and 5kg of prepared coal ash are mixed evenly;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com