Phosphorus-free reverse osmosis membrane scale inhibitor and preparation method thereof

A reverse osmosis membrane and antiscalant technology, which is applied in the field of phosphorus-free reverse osmosis membrane antiscalant and its preparation, can solve the problems of poor scale inhibition effect, unsatisfactory scale inhibition effect, and poor desalination effect, etc. The effect of scale performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A phosphorus-free reverse osmosis membrane scale inhibitor is composed of the following raw materials in mass fraction:

[0035] Polyaspartic acid 12.5%

[0036] Polyepoxysuccinic Acid 58%

[0037] Chitosan 15%

[0038] Polyacrylic acid 7.5%

[0039] Sodium dodecylbenzenesulfonate 3%

[0040] Di(pentamethylcyclopentadienyl)zinc 4%.

[0041] The above-mentioned raw materials were weighed in proportion, and then mixed for 50 minutes at a stirring rate of 100 r / min to obtain a phosphorus-free reverse osmosis membrane scale inhibitor.

[0042] The prepared scale inhibitor was used to desalinate industrial wastewater with a pH of 7.5. The composition of industrial wastewater is shown in Table 1:

[0043] Table 1

[0044] Cu 2+

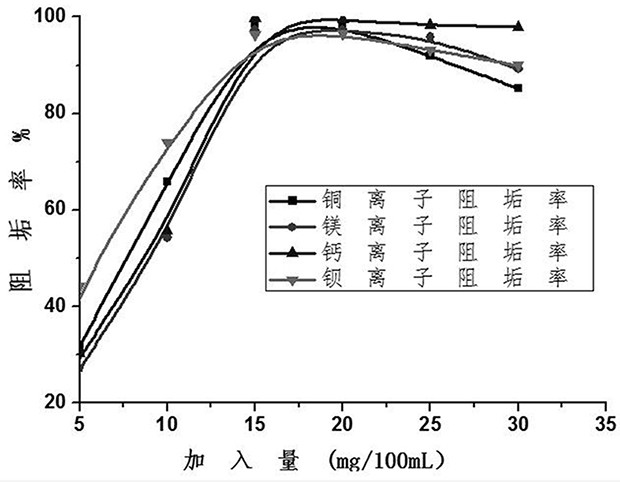

[0045] Weigh 100mL of the above-mentioned industrial wastewater and add 15mg of the phosphorus-free reverse osmosis membrane antiscalant prepared in Example 1, and then carry out ultrasonic mixing treatment at room temperature for...

Embodiment 2

[0052] A phosphorus-free reverse osmosis membrane scale inhibitor is composed of the following raw materials in mass fraction:

[0053] Polyaspartic acid 13%

[0054] Polyepoxysuccinic Acid 60%

[0055] Chitosan 17%

[0056] Polyacrylic acid 5%

[0057] Sodium dodecylbenzenesulfonate 2%

[0058] Di(pentamethylcyclopentadienyl)zinc 3%.

[0059] The above-mentioned raw materials were weighed in proportion, and then mixed for 50 minutes at a stirring rate of 100 r / min to obtain a phosphorus-free reverse osmosis membrane scale inhibitor.

Embodiment 3

[0061] A phosphorus-free reverse osmosis membrane scale inhibitor is composed of the following raw materials in mass fraction:

[0062] Polyaspartic acid 15%

[0063] Polyepoxysuccinic Acid 50%

[0064] Chitosan 20%

[0065] Polyacrylic acid 5%

[0066] Sodium dodecylbenzenesulfonate 5%

[0067] Di(pentamethylcyclopentadienyl)zinc 5%.

[0068] The above-mentioned raw materials were weighed in proportion, and then mixed for 50 minutes at a stirring rate of 1000 r / min to obtain a phosphorus-free reverse osmosis membrane scale inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com