Novel single-layer gas diffusion layer for fuel cell and preparation method and application of novel single-layer gas diffusion layer

A gas diffusion layer and fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems that hinder the commercialization of proton exchange membrane fuel cells, do not meet the concept of healthy and green development, and the cost of gas diffusion layers is high. The method is healthy and green, reduces proton conduction resistance, and is easy to industrialize the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

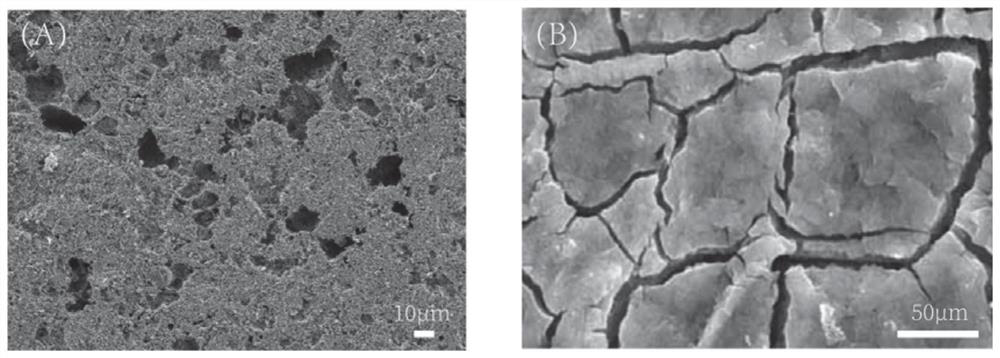

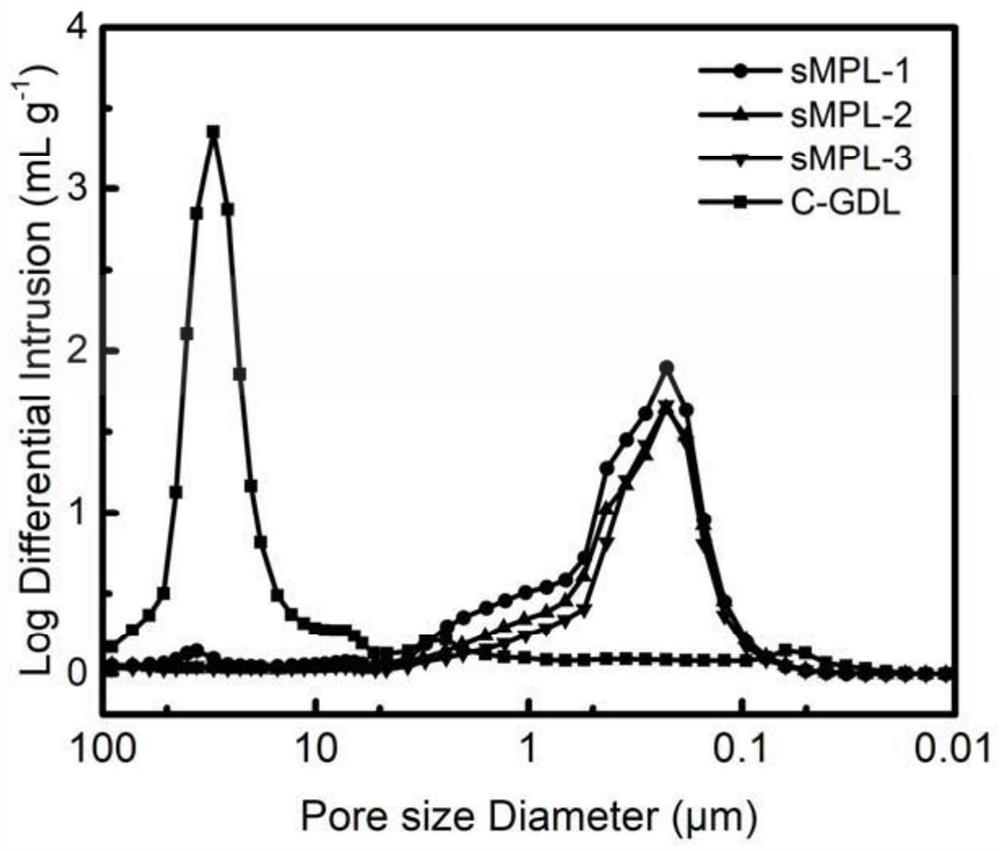

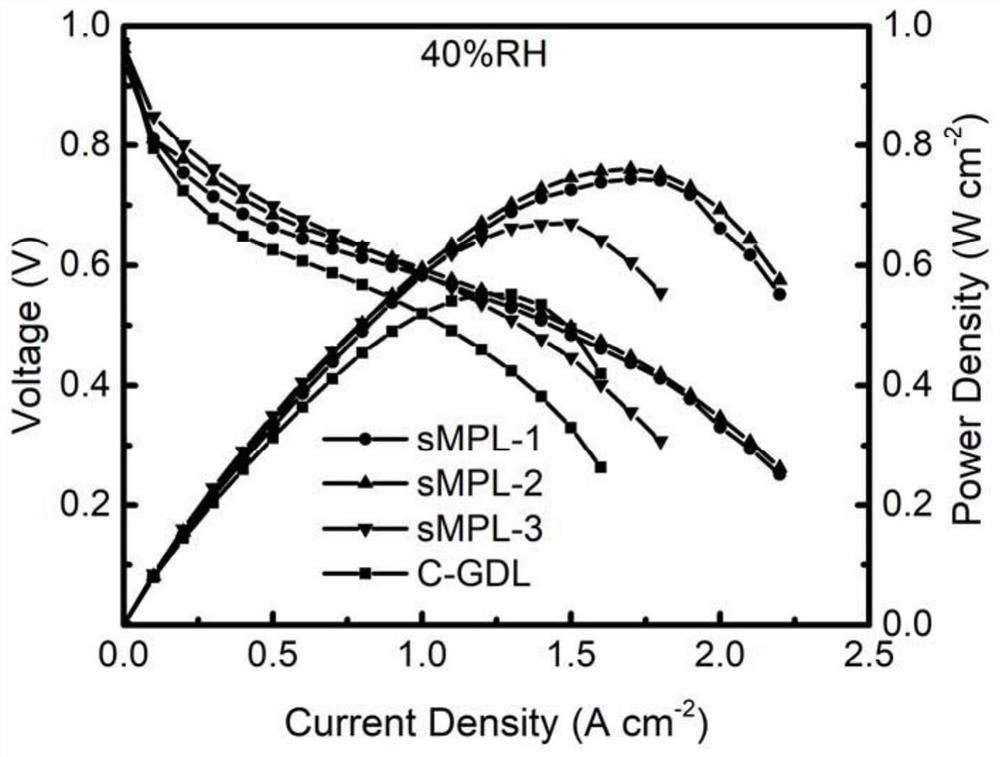

Embodiment 1

[0035] Weigh 1.0g of carbon fiber, 0.075g of hydrophobic binder PVDF, pore forming agent K 2 CO 3 2.0g, mechanically mixed by a pulverizer for 30 minutes, after being fully ground and mixed, spread the evenly mixed mixture in a self-made stainless steel mold to ensure a smooth surface. Then place the mold in a hot press, and first apply a pressure of 0.5 MPa at room temperature for 30 minutes to make the mixture into a sheet. Then release the pressure and heat to raise the temperature to 150°C, heat treatment at 150°C for 20 minutes to make the PVDF evenly distributed in the carbon-free, self-supporting microporous layer. Turn off the heating to allow the mold to cool naturally to room temperature, take out the obtained sheet sample from the mold, and then soak it in HCl solution for 2 hours to remove the pore-forming agent in the microporous layer and form pores inside the microporous layer, wherein the HCl solution The concentration is 2mol L -1 . After acid immersion, ...

Embodiment 2

[0037] Weigh carbon fiber 1.0g, hydrophobic binder PVDF 0.1111g, pore forming agent K 2 CO 3 2.0g, mechanically mixed by a pulverizer for 30 minutes, after being fully ground and mixed, spread the evenly mixed mixture in a self-made stainless steel mold to ensure a smooth surface. Then place the mold in a hot press, and first apply a pressure of 0.5 MPa at room temperature for 30 minutes to make the mixture into a sheet. Then the pressure is released and heated to raise the temperature to 150° C., and heat treatment at 150° C. for 60 minutes to make the PVDF evenly distributed in the carbon-free, self-supporting microporous layer. Turn off the heating to allow the mold to cool naturally to room temperature, take out the obtained sheet sample from the mold, and then soak it in HCl solution for 2 hours to remove the pore-forming agent in the microporous layer and form pores inside the microporous layer, wherein the HCl solution The concentration is 2mol L -1. After acid imm...

Embodiment 3

[0039] Weigh 1.0g of carbon fiber, 0.2g of hydrophobic binder PVDF, pore forming agent K 2 CO 3 2.0g, mechanically mixed by a pulverizer for 30 minutes, after being fully ground and mixed, spread the evenly mixed mixture in a self-made stainless steel mold to ensure a smooth surface. Then place the mold in a hot press, and first apply a pressure of 0.5 MPa at room temperature for 30 minutes to make the mixture into a sheet. Then the pressure was released and heated to raise the temperature to 350°C, and the heat treatment was carried out at 350°C for 60 minutes to make the PVDF evenly distributed in the carbon-free, self-supporting microporous layer. Turn off the heating to allow the mold to cool naturally to room temperature, take out the obtained sheet sample from the mold, and then soak it in HCl solution for 2 hours to remove the pore-forming agent in the microporous layer and form pores inside the microporous layer, wherein the HCl solution The concentration is 2mol L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com