High-pressure-resistant optical fiber cabin-penetrating connector sealed by combined glue and sealing method

A technology of high-voltage resistance and connectors, which is applied in the direction of instruments, optics, light guides, etc., can solve the problems of poor adhesion, low sealing performance, and poor high-temperature resistance, so as to improve high-pressure resistance sealing performance, improve sealing strength, and improve durability. Effects of high pressure sealing performance and high temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

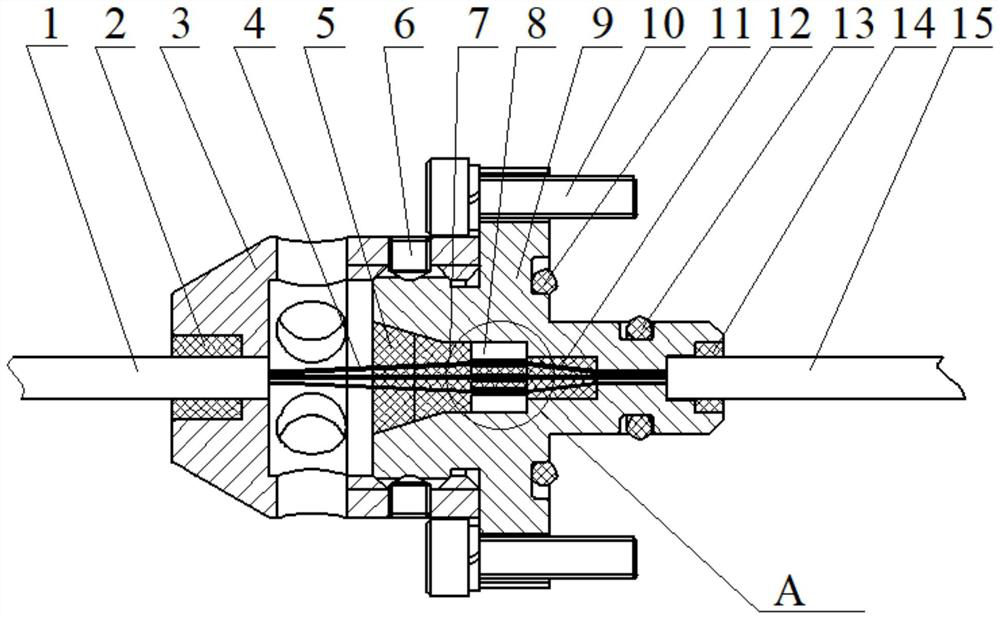

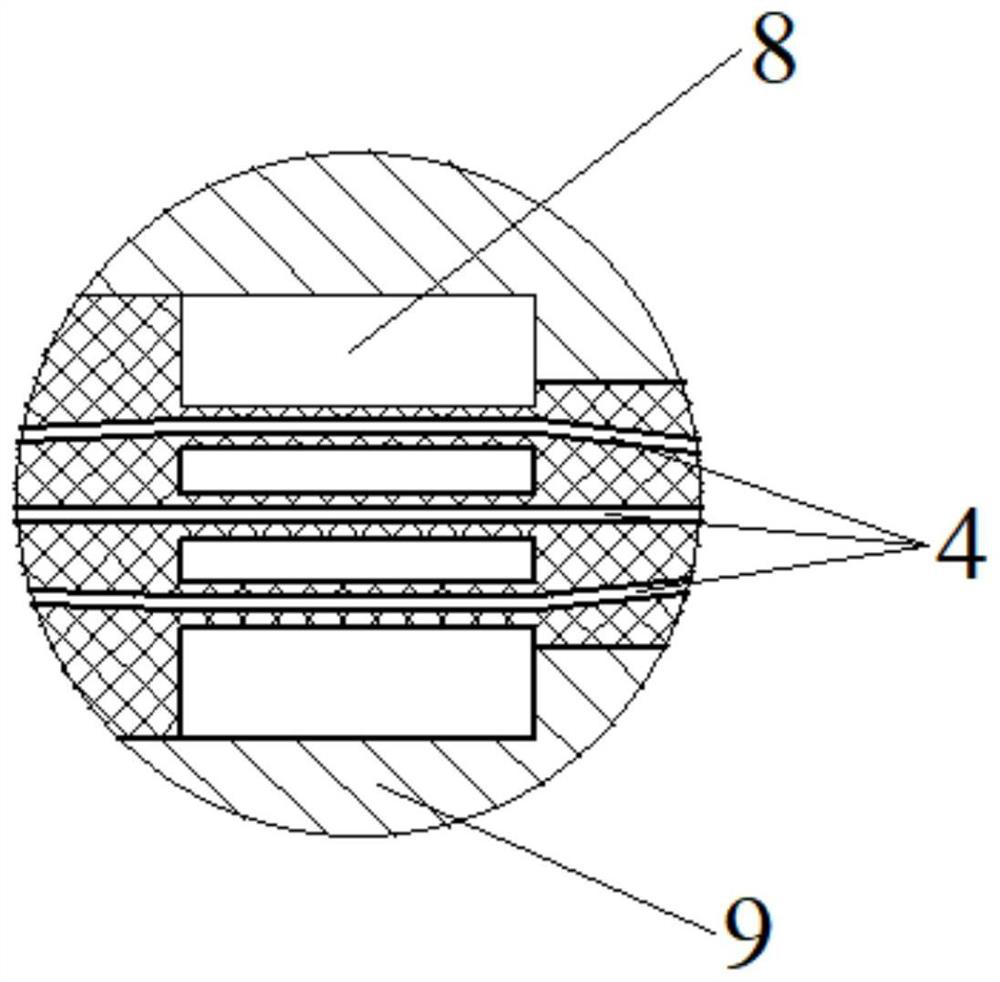

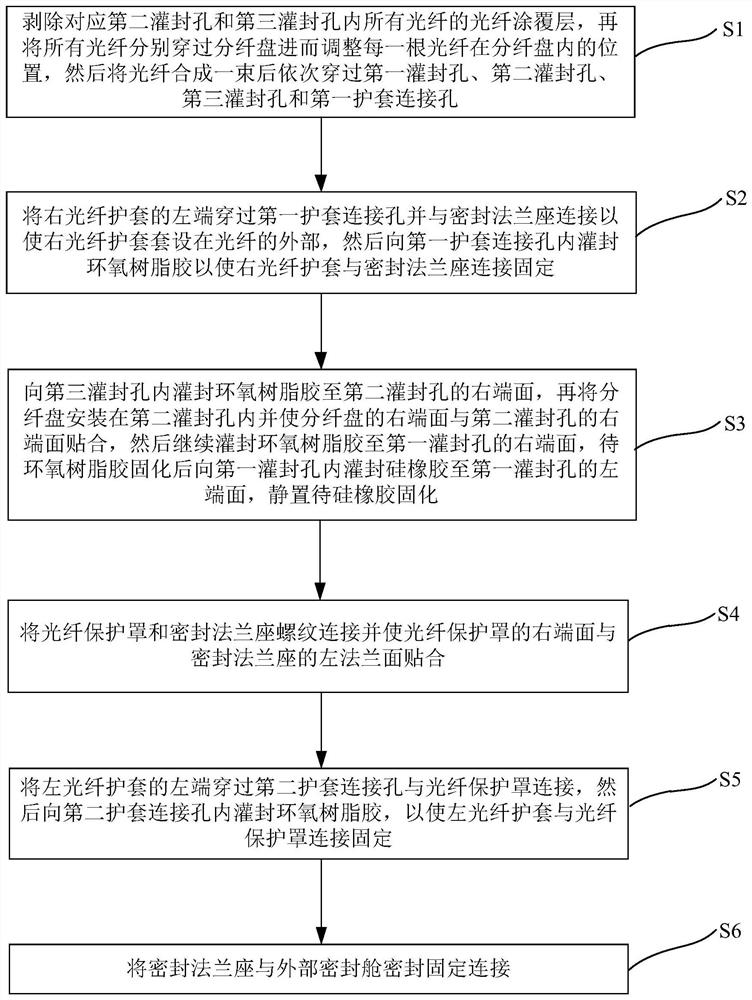

[0028] Such as figure 1 , figure 2 As shown, a combination glue-sealed high-voltage optical fiber cabin penetration connector includes an optical fiber sheath, an optical fiber protective cover 3, a fiber splitter 8 and a sealing flange seat 9, and the sealing flange seat 9 is sealed with the external sealing cabin It is fixedly connected, and the sealing flange seat 9 is provided with a first sheath connecting hole 14 at one end of the outer sealing cabin, and the end of the sealing flange seat 9 away from the outer sealing cabin is provided with a potting hole, and the potting hole includes from left to right The first potting hole 5, the second potting hole 7 and the third potting hole 12 connected in sequence, the first potting hole 5 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com