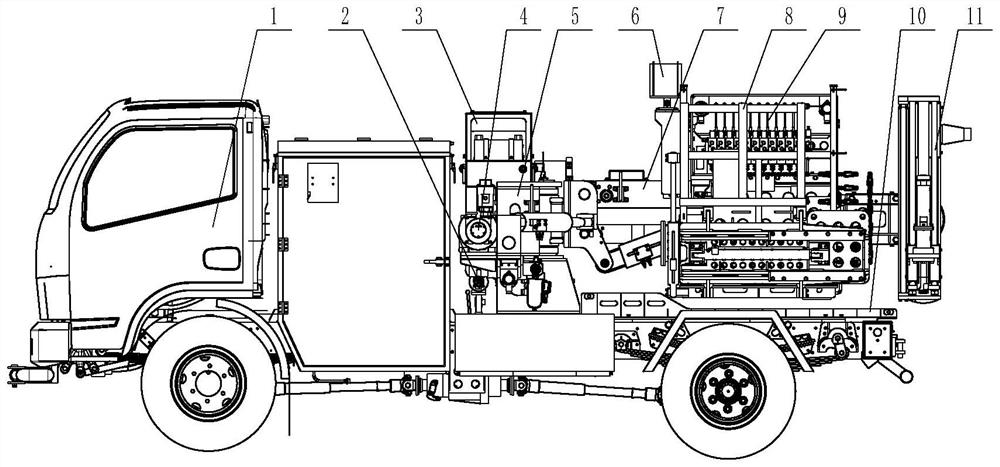

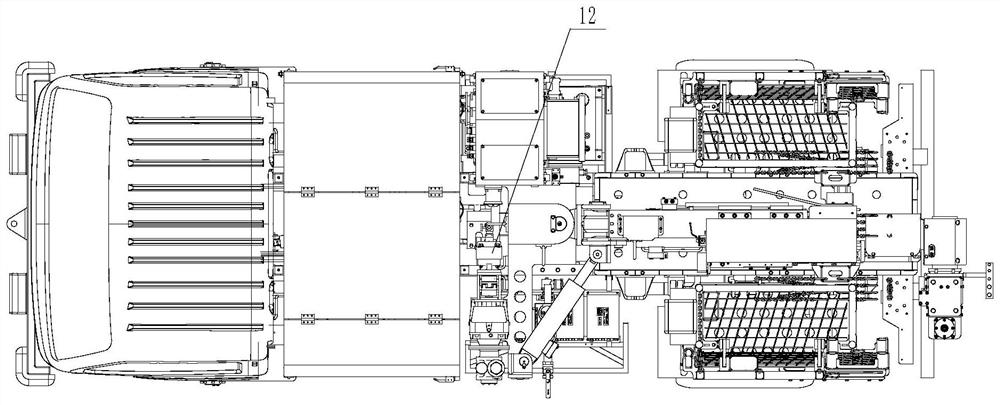

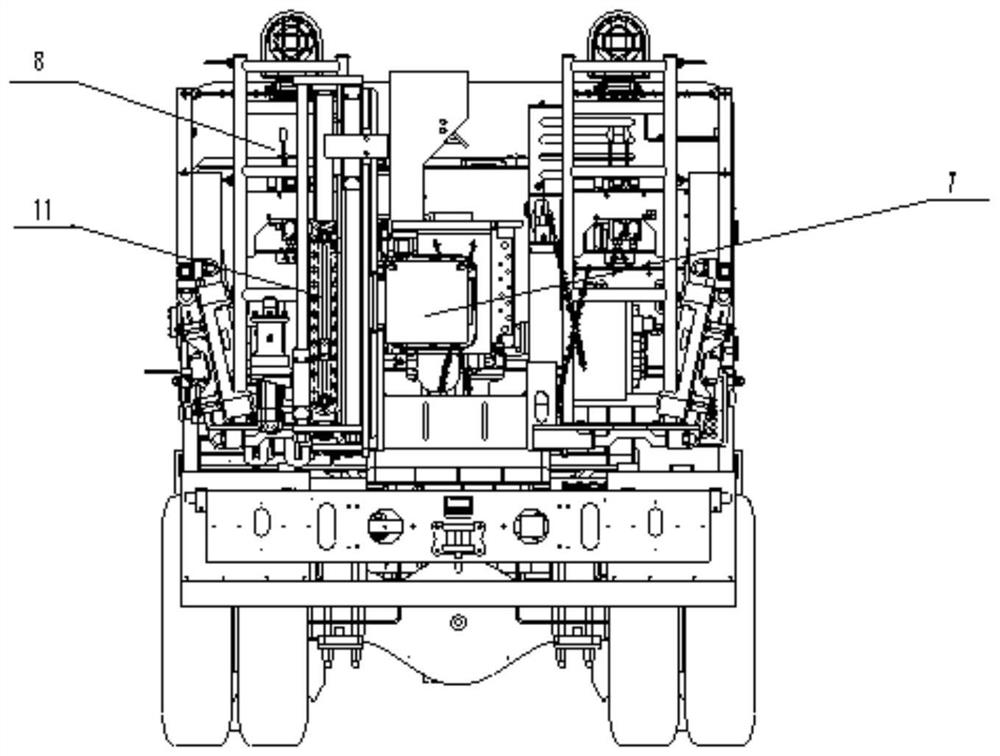

Dual-power hydraulic anchor rod drill carriage

A rock bolter and dual-power technology, which is applied in the direction of motor vehicles, bolt installation, electric vehicles, etc., can solve problems that do not conform to the development concept of green and low-carbon technology, high harmful gas emissions, and poor operating safety. The effect of working range, reducing labor intensity and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0036] It should be noted that, unless otherwise specified, all technical and scientific terms used in this application have the same meaning as commonly understood by those of ordinary skill in the art to which this application belongs.

[0037] In the present invention, unless otherwise specified, the orientation words used such as "upper, lower, top, and bottom" are usually directed at the direction indicated by the drawings, or at the vertical, vertical or vertical position of the component itself. In terms of the direction of gravity; similarly, for the convenience of understanding and description, "inner and outer" refer to the inner and outer relative to the outline of each component itself, but the above orientation words are not used to limit the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com