Nanometer multifunctional cleanup additive for oil field drilling fluid and preparation method thereof

An oilfield drilling and multifunctional technology, which is applied in the field of nanometer multifunctional drainage aids for oilfield drilling fluids and its preparation, can solve the problems of unfavorable modern oilfield operations, increased workload, and increased costs, and achieve the reduction of on-site operation steps, Accessible, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

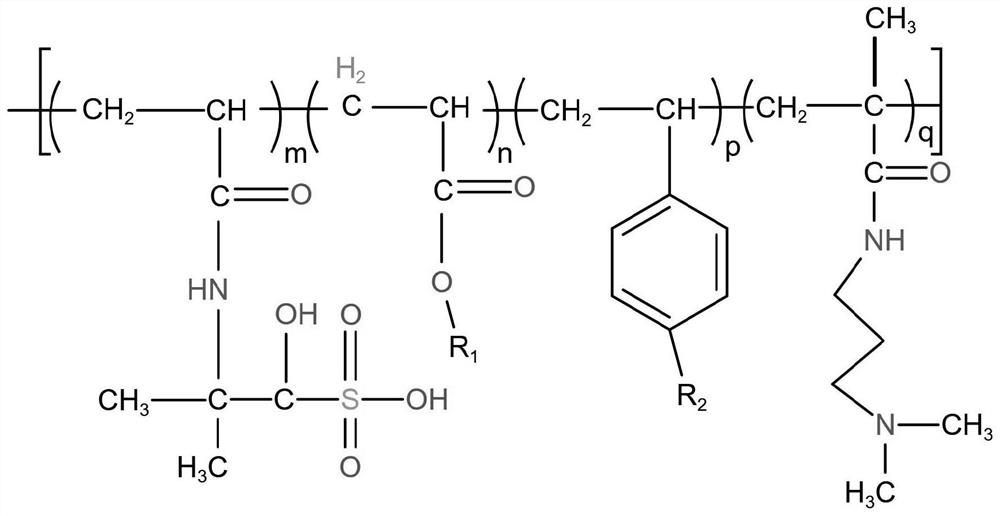

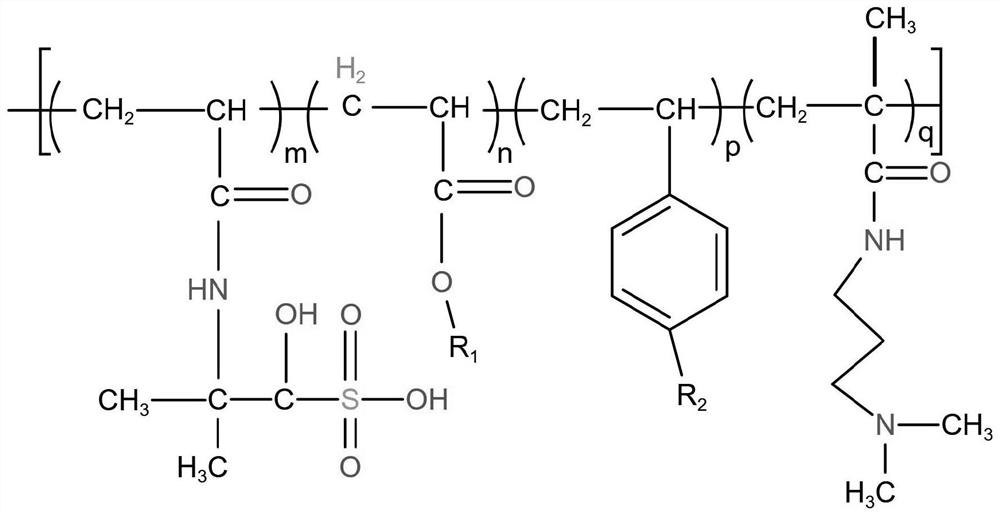

[0025] This embodiment provides a technical solution: a nanometer multifunctional drainage aid for oilfield drilling fluid and its preparation method. The preparation method includes the following steps:

[0026] The first step, prepare nano demulsifier:

[0027] S1. Add 5 parts of butyl acrylate to 0.25 parts of chain transfer agent AMSD, mix and use the mixture (referred to as component A) for later use. 10 parts of styrene and 0.3 parts of chain transfer agent AMSD (referred to as component B) of hydrophobic monomer, 3.5 parts of N-(3-dimethylaminopropyl) methacrylamide and 0.3 part of chain transfer agent of hydrophilic monomer The mixed mixture of the transfer agent AMSD (referred to as component C), and the mixed mixture of 1.5 parts of AMPS and 0.25 part of chain transfer agent AMSD (referred to as component D) are ready for use.

[0028] S2. Add a certain amount of water, 0.15 parts of acetone and 0.32 parts of emulsifier sodium dodecylsulfonate into the four-necked f...

Embodiment 2

[0041] This embodiment provides a technical solution: a nanometer multifunctional drainage aid for oilfield drilling fluid and its preparation method, the preparation method comprising the following steps

[0042] Step 1, self-made nano demulsifier:

[0043] S1. Add 5 parts of butyl acrylate to 0.25 parts of chain transfer agent AMSD, mix and use the mixture (referred to as component A) for later use. 12.5 parts of styrene and 0.3 parts of chain transfer agent AMSD (referred to as component B) of hydrophobic monomer, 2.5 parts of N-(3-dimethylaminopropyl) methacrylamide and 0.3 part of chain transfer agent of hydrophilic monomer The mixed mixture of transfer agent AMSD (referred to as component C), and the mixed mixture of 1 part of AMPS and 0.25 part of chain transfer agent AMSD (referred to as component D) are ready for use.

[0044] S2. Add a certain amount of water, 0.15 parts of acetone and 0.32 parts of emulsifier sodium dodecylsulfonate into the four-necked flask, stir...

Embodiment 3

[0057] This embodiment provides a technical solution: a nanometer multifunctional drainage aid for oilfield drilling fluid and its preparation method. The preparation method includes the following steps:

[0058] Step 1, self-made nano demulsifier:

[0059] S1. Add 5 parts of butyl acrylate to 0.25 parts of chain transfer agent AMSD, mix and use the mixture (referred to as component A) for later use. 10 parts of styrene and 0.3 parts of chain transfer agent AMSD (referred to as component B) of hydrophobic monomer, 3.5 parts of N-(3-dimethylaminopropyl) methacrylamide and 0.3 part of chain transfer agent of hydrophilic monomer The mixed mixture of the transfer agent AMSD (referred to as component C), and the mixed mixture of 1.5 parts of AMPS and 0.25 part of chain transfer agent AMSD (referred to as component D) are ready for use.

[0060] S2. Add a certain amount of water, 0.15 parts of acetone and 0.32 parts of emulsifier sodium dodecylsulfonate into the four-necked flask, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com