Shiftable bulk material ship loader

A ship loader and material technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of scattering, affecting the function of the ship loader, lack of waste collection mechanism, etc., and achieve the effect of preventing entanglement and confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

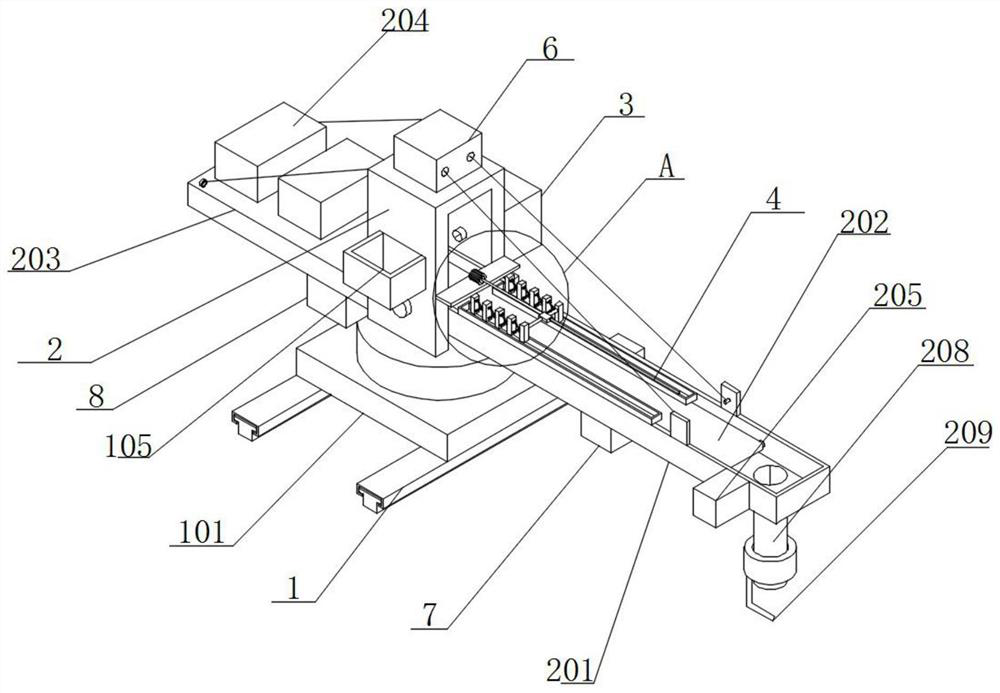

[0047] Example 2: see Figure 4 and Figure 5 , an embodiment provided by the present invention: a ship loader for bulk materials that can be transferred, the inner bottom wall of the dust collector 3 is equipped with a waterproof chamber, the inner bottom wall of the waterproof chamber is installed with a water pump 301, and the outer wall of the water pump 301 is installed There is a controller, and a storage box is installed on the inner bottom wall of the dust collector 3, and the storage box is located on one side of the waterproof chamber, and a water inlet pipe is installed at the input end of the water pump 301, and one end of the water inlet pipe extends out of the outer wall of the dust collector 3, and enters One end of the water pipe is connected to the external water tank, the output end of the water pump 301 is provided with an outlet pipe, and one end of the outlet pipe extends into the storage tank, the top of the waterproof cavity is equipped with a booster pu...

Embodiment 3

[0048] Example 3: See figure 1 , Figure 10 and Figure 12 , an embodiment provided by the present invention: a bulk material ship loader that can be transferred, the inner walls of both sides of the fixed chute 4 are equipped with limit plates 401, and the inner bottom wall of the fixed chute 4 is equipped with rollers 402, the rollers The top of 402 is equipped with a support rod 403, and the outer wall of the support rod 403 is equipped with two sets of intersecting connecting rods 404 through bearings, and the connecting rods 404 are connected by bearings. The top of 5 is equipped with an adjusting motor 501, the output end of the adjusting motor 501 is equipped with a reciprocating screw rod, the outer wall of the reciprocating screw rod is equipped with a moving block 502, and the outer wall of the moving block 502 is connected with the support rod 403 by a fixed rod, and the transmission When feeding materials, start the adjustment motor 501, the adjustment motor 501 ...

Embodiment 4

[0049] Example 4: See figure 2 and image 3, an embodiment provided by the present invention: a bulk material ship loader that can transfer fields, a drive motor 601 is installed on the inner wall of the cable retractor 6, and a steel cable 602 is installed around the output end of the drive motor 601, and the wire The inner top wall of the cable retractor 6 is equipped with a fixed groove 603, the inner bottom wall of the fixed groove 603 is equipped with a pulley 604, the outer wall of the fixed groove 603 is installed with a telescopic column 605, and one end of the telescopic column 605 is equipped with a driver 606. The inner walls of both sides of 606 are equipped with lifting grooves 607, and the outer walls of the lifting grooves 607 are equipped with lifting plates 608. A plurality of latching teeth 610 are installed, and a converging motor 611 is installed on the inner rear wall of the cable retractor 6, and a driving gear is installed on the output end of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com