A kind of unidirectional long hemp fiber prepreg production line and production process

A prepreg and production line technology, applied in fiber treatment, coating, deburring devices, etc., can solve problems such as lack of straightness, high fiber arrangement density, and scattered long hemp strips, so as to improve transverse adhesion , reduce preparation costs, and avoid overlapping effects

Active Publication Date: 2022-04-29

TIANJIN POLYTECHNIC UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The preparation of existing unidirectional fiber prepregs is made of carbon fiber, glass fiber, aramid fiber and other filament bundles as raw materials, and the fiber straightness is high and continuous. The device diffuses the fibers horizontally and makes the large tow thinner. Common yarn spreading methods include mechanical multi-roller fiber expansion method, air jet fiber expansion method, ultrasonic fiber expansion method, sonic fiber expansion method, etc., but the existing These fiber expansion methods cannot meet the requirements of horizontal fiber expansion of long hemp sliver, because the long hemp fiber is in a discontinuous state in the hemp sliver, and a continuous fiber sliver is formed by overlapping and frictional entanglement between fibers. Conventional fiber expansion methods During the process of applying to the long sliver, the head and tail of the fibers in the sliver are drawn out, resulting in the scatter of the long sliver, the reduction of fiber orientation, and even serious roll entanglement

In addition, the thickness of the long hemp sliver is relatively large, and after the long hemp sliver is no longer stretched by tension, the fiber has obvious retraction phenomenon, and the straightness is lacking.

[0006] The document with application number 201510312438.8 discloses a preparation method of hemp fabric prepreg and composite material. In this method, hemp fabric is used as reinforcement and combined with resin to prepare composite material. Composed of twisted and entangled root fibers, the fibers are closely arranged, the resin is not easy to infiltrate the fabric, and there is an angle between the fiber axis and the direction of the composite material, which leads to the inability of the fiber to fully exert its excellent mechanical properties during the load-bearing process of the composite material.

[0007] To sum up, the existing conventional prepreg processing devices and equipment are not suitable for the preparation of unidirectional prepreg with long hemp roving as raw material

Method used

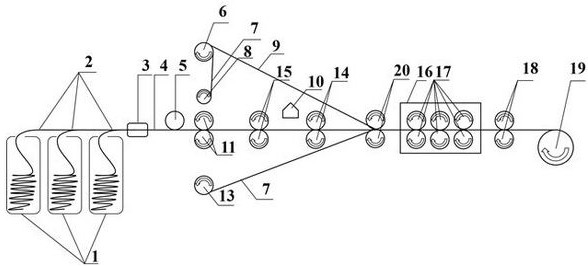

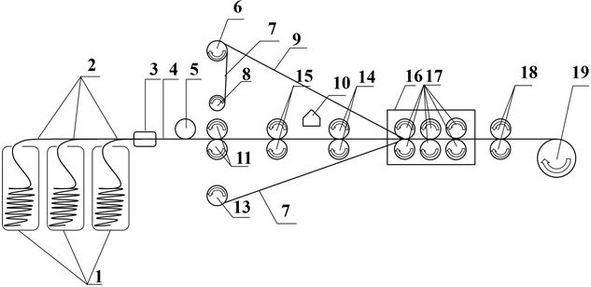

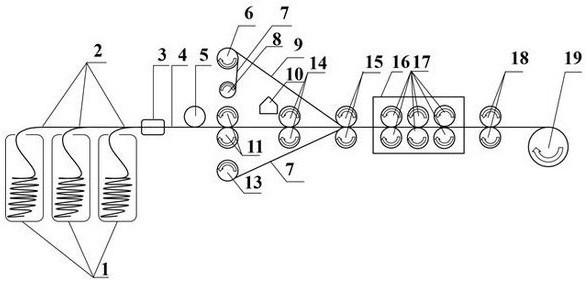

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0073] Adopt the preparation device of unidirectional long hemp fiber prepreg of the present invention to prepare long hemp fiber prepreg, the linear density of used long hemp sliver 2 is 1500-5000tex (the weight of every 1000 meters of long hemp sliver is between 1500g-5000g , the average fiber length is 15-25cm);

[0074] The unidirectional long hemp fiber prepreg is prepared by adopting the production process described in the invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a unidirectional long hemp fiber prepreg production line and a production process. The production line is equipped with feeding device, fiber spreading device, drafting station, shaping station, laminating station, hot pressing device and conveying roller in sequence according to the fiber conveying direction. The present invention innovatively develops a set of unidirectional long hemp fiber prepreg production line and process using long hemp sliver as raw material, which is simple and easy to implement. Since long hemp sliver is used as feeding raw material, the processing of long hemp sliver is less difficult and the process flow It is short and fast, which can significantly reduce the preparation cost of prefabricated reinforcement materials; the output width and thickness can be designed, and the long hemp fiber tape and the long hemp fiber inside the prepreg have high straightness; suitable for large quantities of unidirectional long hemp fiber The continuous production of tapes and prepregs fills the gap in the industry.

Description

technical field [0001] The invention relates to the field of hemp fiber prepreg preparation, in particular to a unidirectional long hemp fiber prepreg production line and a production process. Background technique [0002] As a natural renewable material, plant fiber has the advantages of cheap, recyclable, degradable, renewable, etc., and has the strength and stiffness of ordinary fibers, and its density is low, so its specific strength and specific modulus are high. Composite materials with natural plant fibers as reinforcements have the same excellent performance. Therefore, with the development of science and technology and the increasingly tense environment of global non-renewable resources, high-performance natural fiber composite materials represented by hemp fibers are used in automobiles, buildings, The application in decoration and other fields is more and more extensive. [0003] However, the length of natural hemp fibers is limited. In order to obtain continuous...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C70/50B29B15/12B29B15/14B29C70/54B29C70/20D02J1/18D02J1/22D01G15/02D01G15/14

CPCB29C70/504B29B15/125B29B15/14B29C70/54B29C70/20D02J1/18D02J1/22D01G15/02D01G15/14

Inventor 王春红鹿超陈莉张彦春王利剑

Owner TIANJIN POLYTECHNIC UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com