Machine tool buffering mechanism for motor shaft machining

A buffer mechanism and motor shaft technology, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem that the overall structure of the fixed motor shaft is not stable enough, so as to avoid debris flying around, improve stability, and improve stability. The effect of the support limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

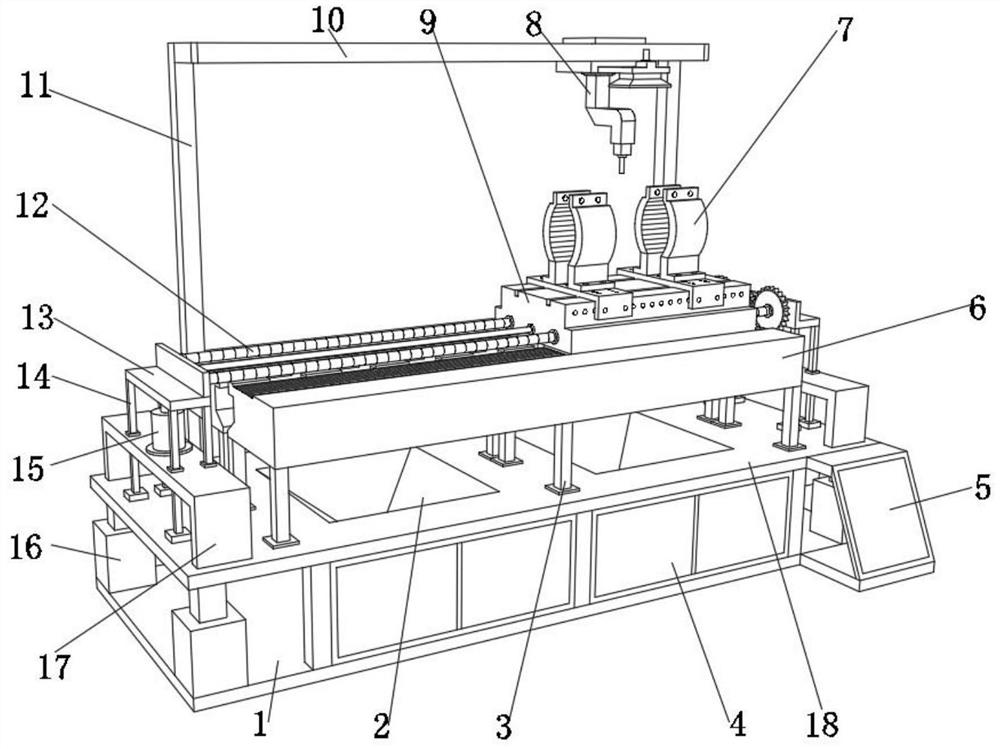

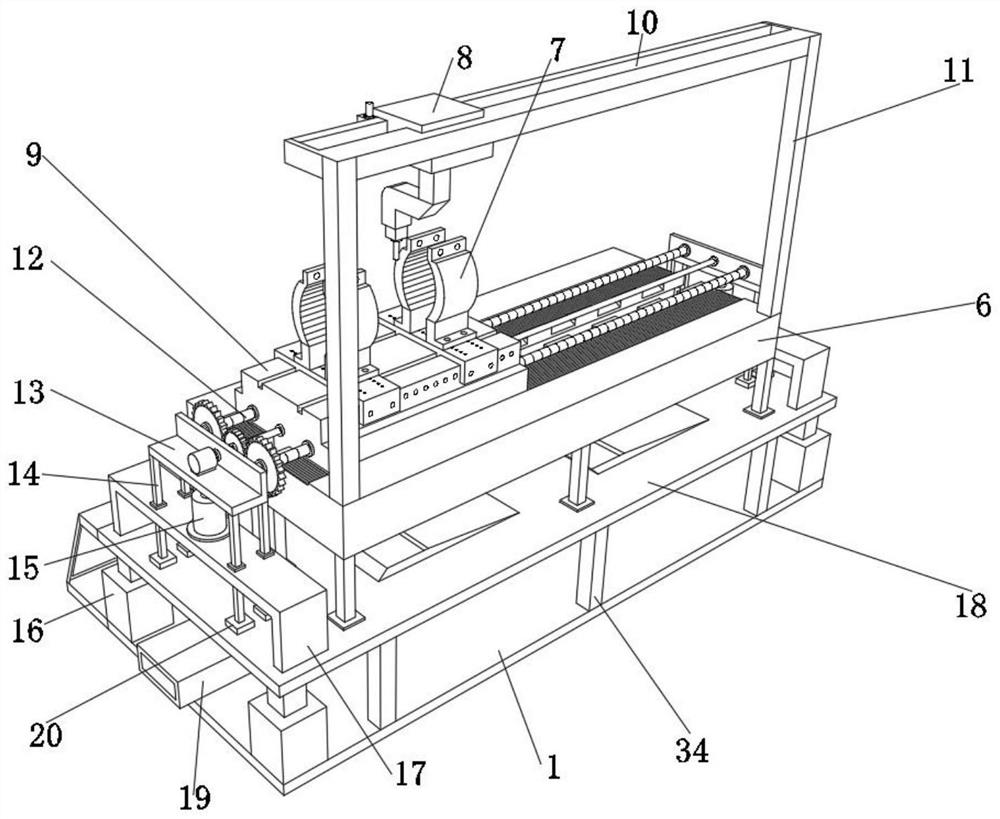

[0035] A machine tool buffer mechanism for motor shaft processing, such as Figure 1-8As shown, including the base plate 1, the outer wall of the top of the base plate 1 is fixed with a plurality of second support columns 34 by screws, the outer wall of the top of the second support column 34 is fixed with a support plate 18, and the outer wall of the top of the support plate 18 is fixed by screws. A first support column 3, the outer wall of the top of the first support column 3 is fixed with a set of mounting table 6 by screws, the outer wall of the top of the mounting table 6 is provided with a processing table 9, and the outer wall of one side of the processing table 9 is provided with a group of circular through holes. The inner wall of the through hole is provided with an internally threaded sleeve 35, and the inner wall of the internally threaded sleeve 35 is threadedly connected with an electric screw rod 12. The staff can control the electric screw rod 12 through the co...

Embodiment 2

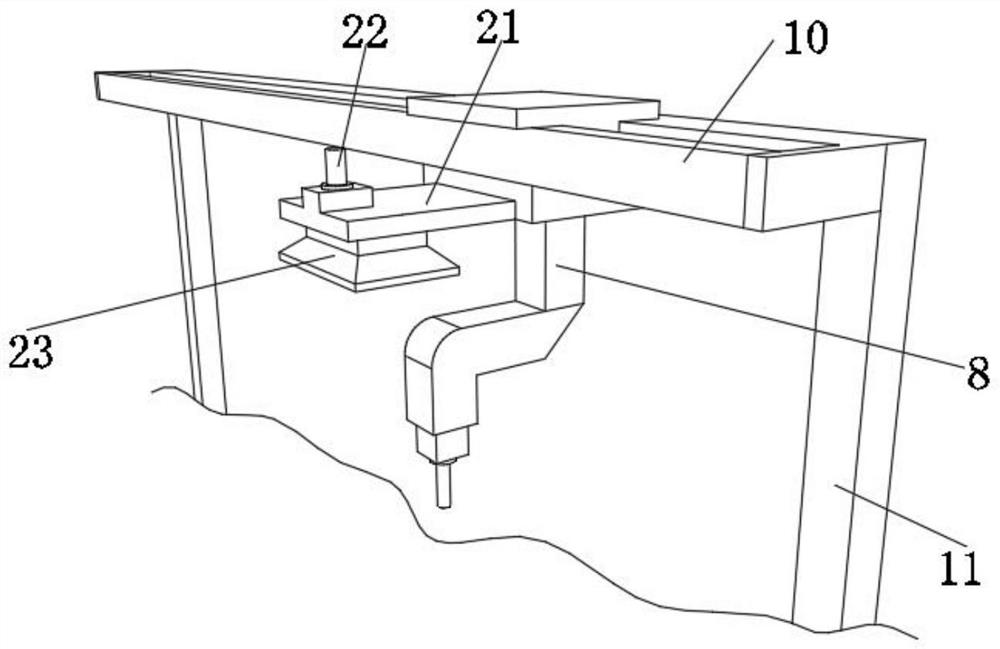

[0044] A machine tool buffer mechanism for motor shaft processing, such as figure 1 , image 3 As shown, in order to avoid debris flying randomly when processing the motor shaft; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of one side of the processing manipulator 8 is fixed with a connecting plate 21 by screws, and the outer wall of the top of the connecting plate 21 passes through The screw is fixed with an electric control water valve 22, and the outer wall of the bottom of the connecting plate 21 is fixed with a water spray plate 23, and the electric control water valve 22 is electrically connected with the control panel 5; During the hole cutting process, a large amount of metal debris will be generated. The staff will connect the electric control water valve 22 with the outer wall water pump through the pipeline, and the control panel 5 can control the electric control water valve 22 to open. 22 Inject water flow into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com