PCCP bell and spigot full-automatic production system and process

A fully automated, production system technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve problems such as unqualified welding, achieve automatic welding, improve production efficiency, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

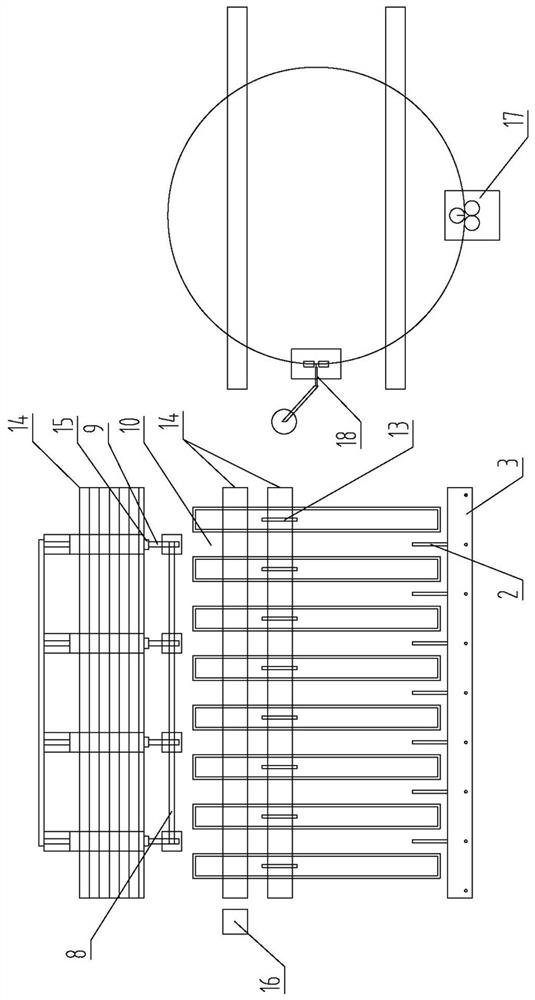

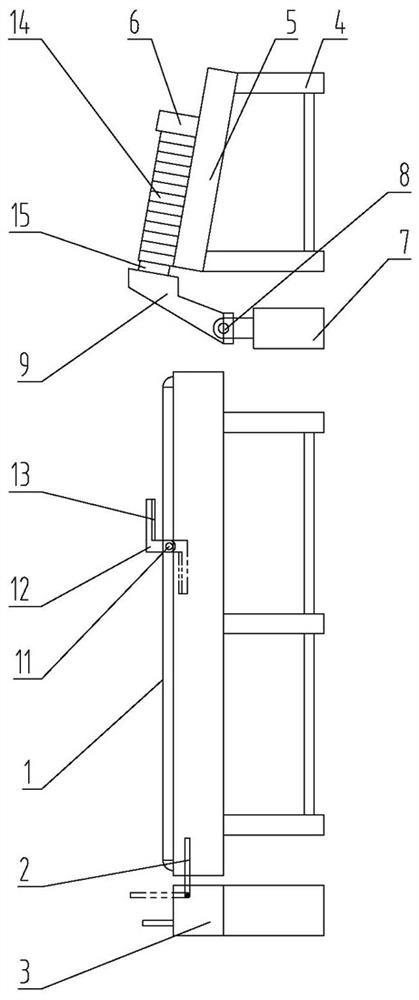

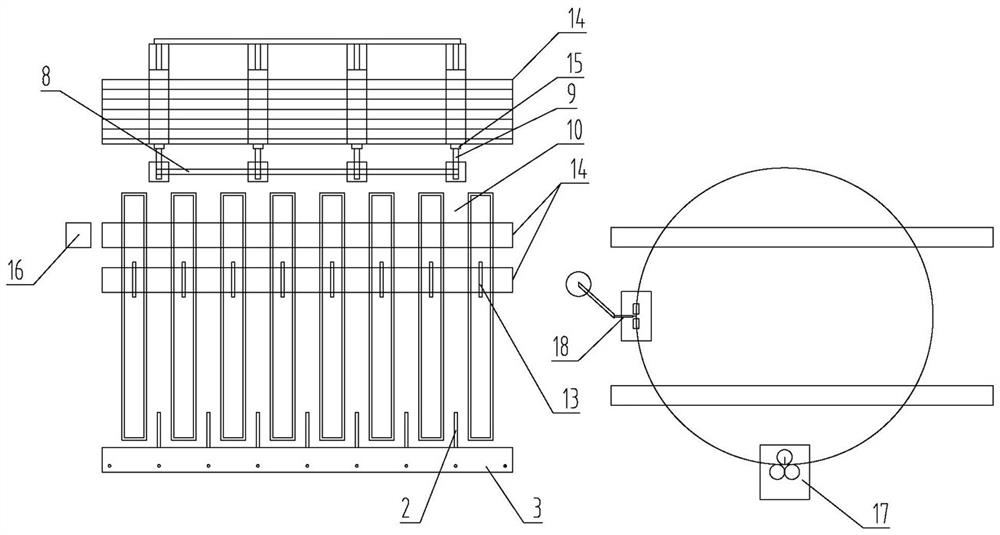

[0025] Example 1, such as figure 1 , 2 As shown, the PCCP socket fully automated production system and process include feeding parts, turning and transferring parts, belt conveying line 1, processor, 90-degree turning roller 2, roller conveying line 3, plate rolling machine 17 and welding machine 18; The turning and transferring part that absorbs and flips the sheet material to the belt conveyor line 1 is installed between the feeding part and the belt conveyor line 1; between the head end and the end of the belt conveyor line 1, a visual recognition device 16, a turning surface mechanism; the visual recognition instrument 16 is connected to the input end of the processor, and the output end of the processor is connected to the turning mechanism that can switch between the two states of flipping the sheet or not affecting the conveying of the sheet; the sheet can be turned over and sent The 90-degree overturning drum 2 that enters the drum conveyor line 3 is installed at the ...

Embodiment 2

[0035] Example 2, such as figure 1 , 2 As shown, the fully automated production process of the PCCP socket includes the following steps: the first step is to operate the hoisting equipment to hoist the socket sheet 14 into the storage rack 5 and place it on the sheet holder 6; the second step , the motor drives the first through shaft 8 to rotate, and after the first electromagnet 15 on the first turning hand 9 is attached to the highest-end socket sheet 14, the first electromagnet 15 is started to work, and the highest-end socket sheet 14 is fixed. The motor drives the first through shaft 8 to rotate in reverse, the first turning hand 9 rotates to the interval channel 10, the socket sheet 14 is placed on the belt conveyor line 1, and the work of the first electromagnet 15 is stopped; in the third step, the bearing The socket sheet 14 is transported along the belt conveyor line 1, and the front and back sides of the raw material are identified by the visual recognition instru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com