Casting powder for continuous casting crystallizer and preparation method of casting powder

A technology for continuous casting mold and mold slag, which is applied in the field of continuous casting mold mold slag and its preparation, which can solve the problems of difficult control of heat transfer process, influence on billet quality, low carbon black ratio, etc., and reduce excessive cooling speed , reduce heat transfer efficiency, and stabilize chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A continuous casting mold powder, including the following components SiO 2 24.00kg, CaO26.00kg, Al 2 o 3 5.40kg, Fe 2 o 3 3.00kg, MgO3.00kg, Na 2 O and Li 2 06.5kg, CaF 2 3.50-7.50 parts, ZrO 2 4.5-5.5 parts, Y 2 o 3 3.5-4.5 parts, of which Na 2 O and Li 2 0 has a weight ratio of 1:1.

[0029] A preparation method of continuous casting mold powder: 24.00kgSiO 2 , 26.00kgCaO, 5.40kgAl 2 o 3 、3.00kgFe 2 o 3 , 3.00kgMgO, 3.50kgCaF 2 , 4.5kgZrO 2 、3.5kgY 2 o 3 , 6.50kgNa 2 O and Li 2 0, mix evenly, use a ball mill to grind, and dry to obtain the finished mold slag powder slag, the particle size of the finished mold slag powder slag corresponds to the mesh number of 100 mesh, wherein Na 2 O and Li 2 The weight ratio of 0 is 1:1, CaO and SiO 2 The weight ratio is 1.08:1.

Embodiment 2-9 and comparative example 1-2

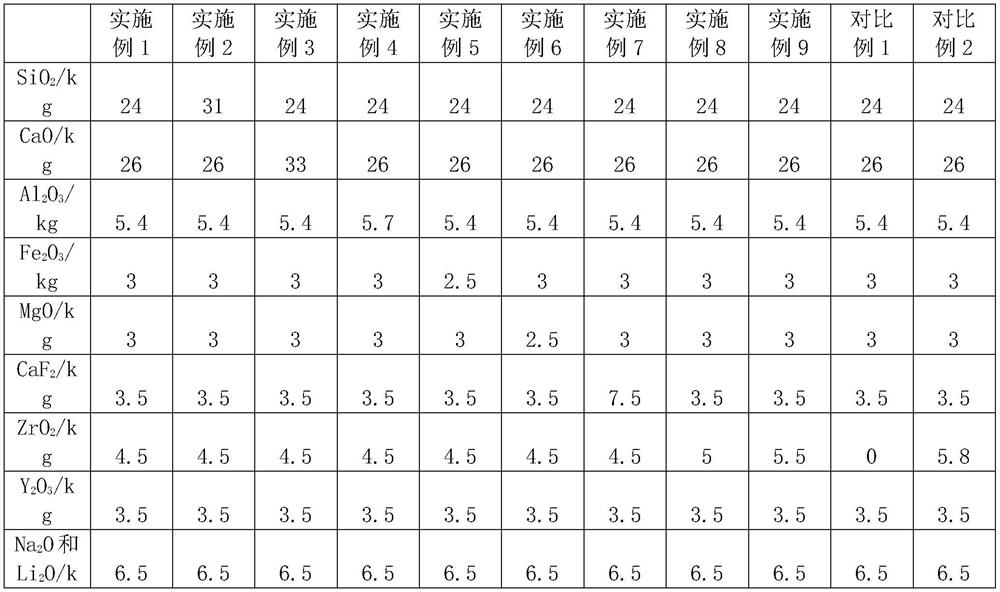

[0031] The difference between Examples 2-9 and Comparative Examples 1-2 and Example 1 is that the ratio of raw materials is different, and the specific ratio of raw materials is shown in Table 1-1 and Table 1-2.

[0032] Table 1-1 embodiment 2-9 and the raw material proportioning of comparative example 1-2

[0033]

[0034]

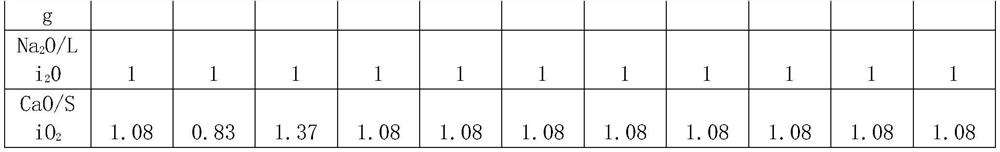

[0035] Set the mass of each example in Table 1-1 as 1kg, and the rest of the data will be changed accordingly as shown in the following table:

[0036] Table 1-2 embodiment 2-9 and the raw material ratio of comparative example 1-2

[0037]

[0038] performance test

[0039] Viscosity test: According to the standard YB / T185-2017 continuous casting mold flux viscosity test method, the mold flux viscosity test is tested.

[0040]Heat transfer efficiency test method: use HF-200 crystallizer slag film heat flow simulator to test the heat flux density of mold flux.

[0041] Preparation steps of heat flow tester slag film: at 1300°C, mix 350g of the ...

Embodiment 10-14 and comparative example 3-4

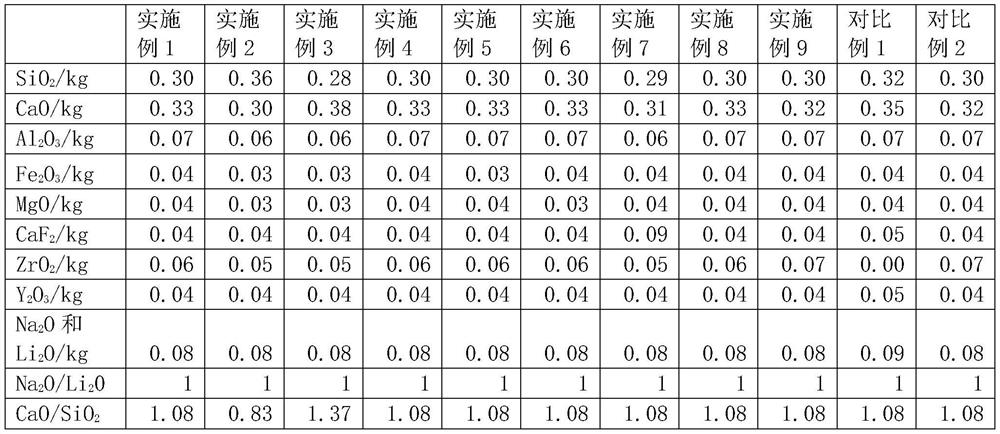

[0056] The difference between Examples 10-14 and Comparative Examples 3-4 and Example 1 is that the raw material ratio is different, and the specific raw material ratio is shown in Table 3-1 and Table 3-2.

[0057] Table 3-1 embodiment 10-14 and the raw material proportioning of comparative example 3-4

[0058]

[0059]

[0060] Set the mass of each example in Table 3-1 as 1kg, and the rest of the data changes accordingly as shown in the following table:

[0061] Table 3-2 embodiment 10-14 and the raw material proportioning of comparative example 3-4

[0062] Example 10 Example 11 Example 12 Example 13 Example 14 Comparative example 3 Comparative example 4 SiO 2 / kg

0.30 0.29 0.30 0.33 0.29 0.32 0.29 CaO / kg 0.32 0.31 0.33 0.31 0.33 0.34 0.32 Al 2 o 3 / kg

0.07 0.06 0.07 0.07 0.07 0.07 0.07 Fe 2 o 3 / kg

0.04 0.04 0.04 0.04 0.04 0.04 0.04 MgO / kg 0.04 0.04 0.04 0.04 0.04 0.04 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com