Composite prepreg and ethylene propylene diene monomer heat insulation layer co-curing adhesive film and preparation method thereof

A technology of EPDM rubber and composite materials, which is applied in the direction of carboxyl rubber adhesives, adhesives, epoxy resin glue, etc., and can solve the problems of poor stability of gluing process, difficulty in controlling the thickness of the glue layer, and poor reliability of bonding, etc. problem, to achieve the effect of accurate and controllable quality per unit area, uniform film thickness and good paving property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

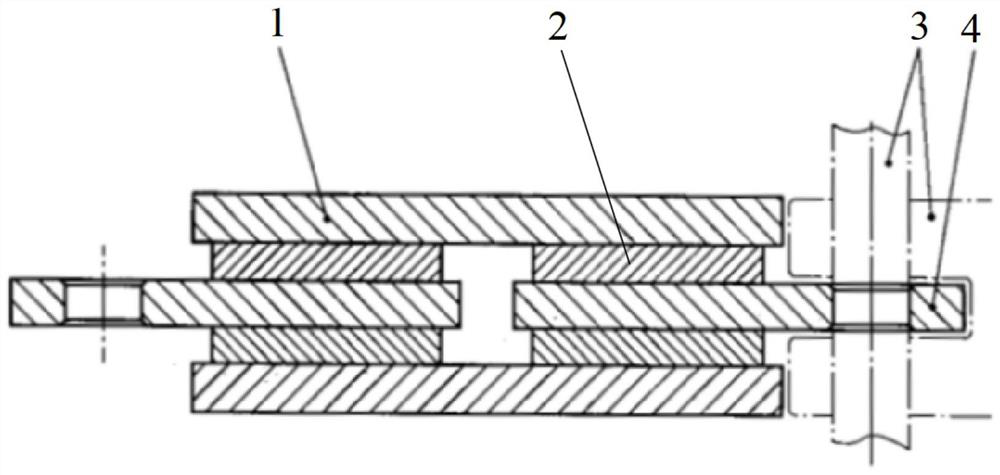

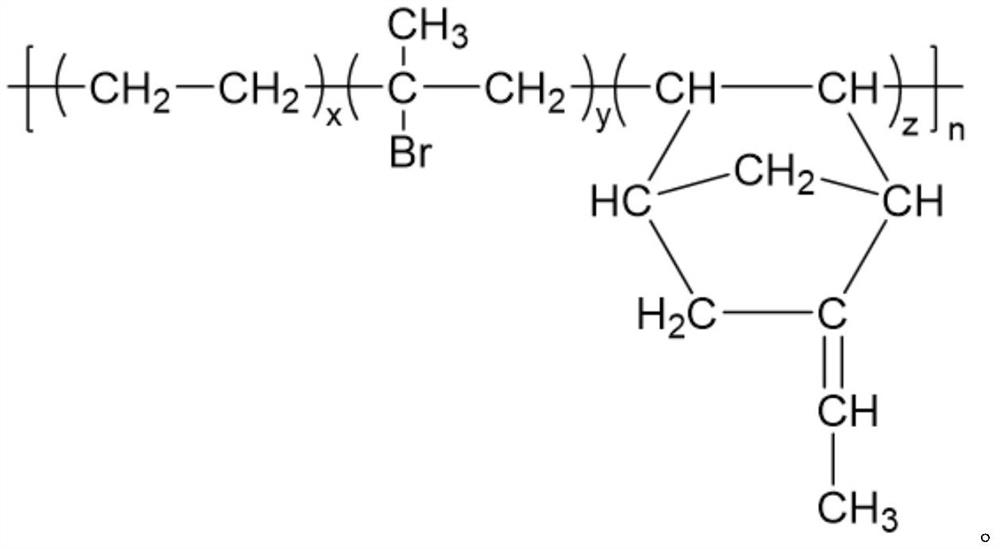

[0017] Specific implementation mode 1: In this embodiment, the composite material prepreg and the EPDM rubber insulation layer are co-cured and the adhesive film is composed of 30-50 parts by weight of the main resin, 25-45 parts of the main toughening agent, and 10-50 parts by weight. Prepared by 25 parts of auxiliary toughening agent, 5-15 parts of curing agent, 3-12 parts of vulcanizing agent and 1-4 parts of filler;

[0018] The main resin is composed of side chain epoxy resin containing naphthalene ring structure and other epoxy resins, wherein the side chain epoxy resin containing naphthalene ring structure accounts for 40% to 50% of the mass of the main resin; the other epoxy resins The resin is one of bisphenol A type epoxy resin, trifunctional alicyclic epoxy resin and o-cresol novolak type epoxy resin or a mixture of several of them.

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the structural formula of the side chain containing naphthalene ring structure epoxy resin described in step one is:

[0020] The structural formula of described trifunctional alicyclic epoxy resin is:

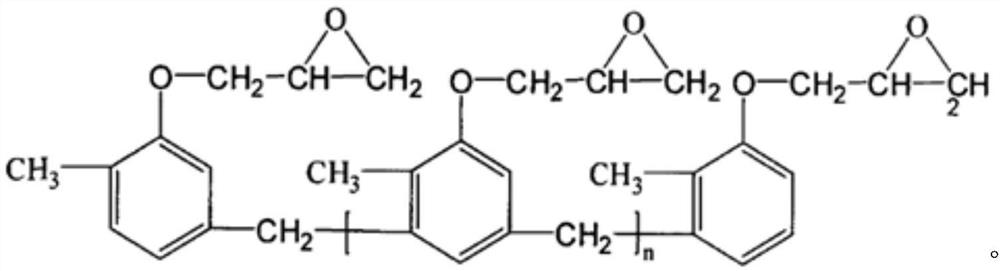

[0021] The structural formula of described o-cresol novolak type epoxy resin is:

[0022] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the composite material prepreg and the EPDM rubber insulation layer are co-cured and the adhesive film is composed of 30 to 45 parts by weight. It is prepared by resin, 30-45 parts of main toughening agent, 15-20 parts of auxiliary toughening agent, 8-12 parts of curing agent, 6-9 parts of vulcanizing agent and 2-4 parts of filler. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com