Method for preparing two-dimensional material Ti3C2 by taking Ti3SiC2 as precursor

A technology of two-dimensional materials and precursors, applied in the direction of carbide, titanium carbide, etc., can solve the problems of harsh conditions of two-dimensional materials, and achieve the effects of low cost, abundant synthesis methods, and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

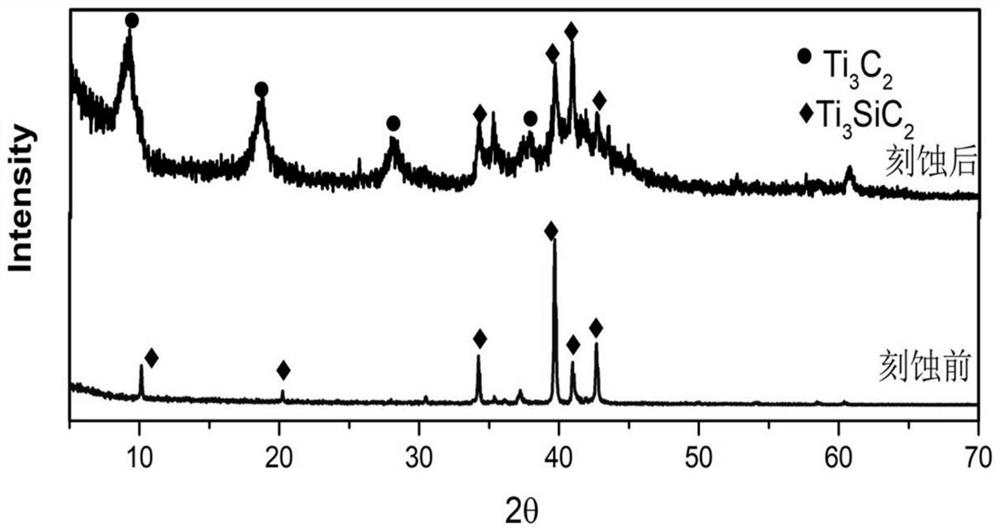

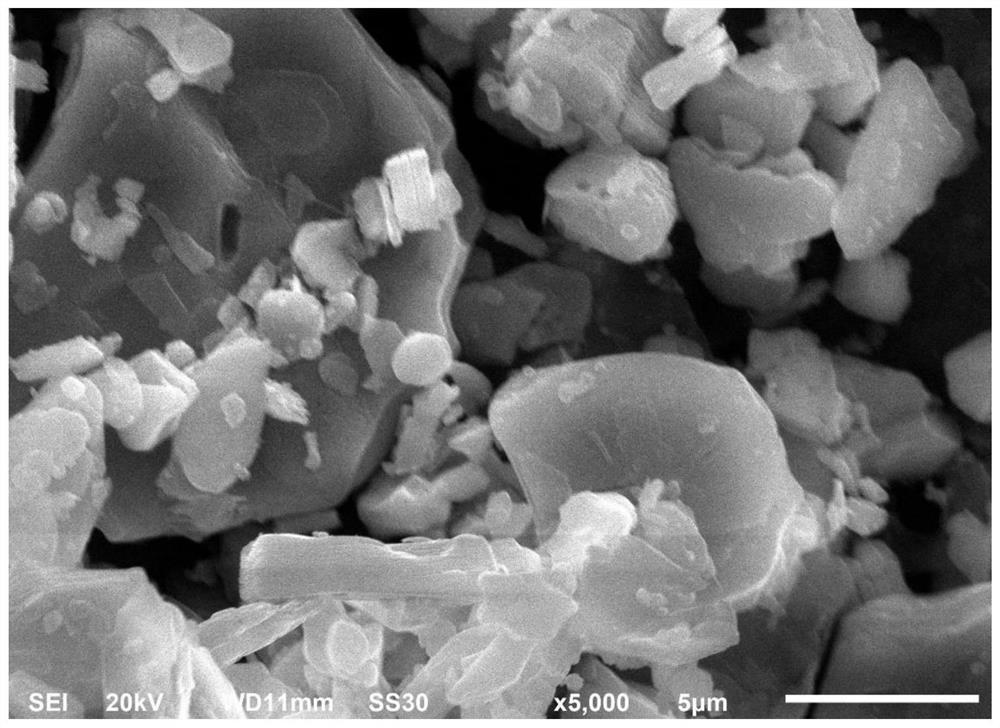

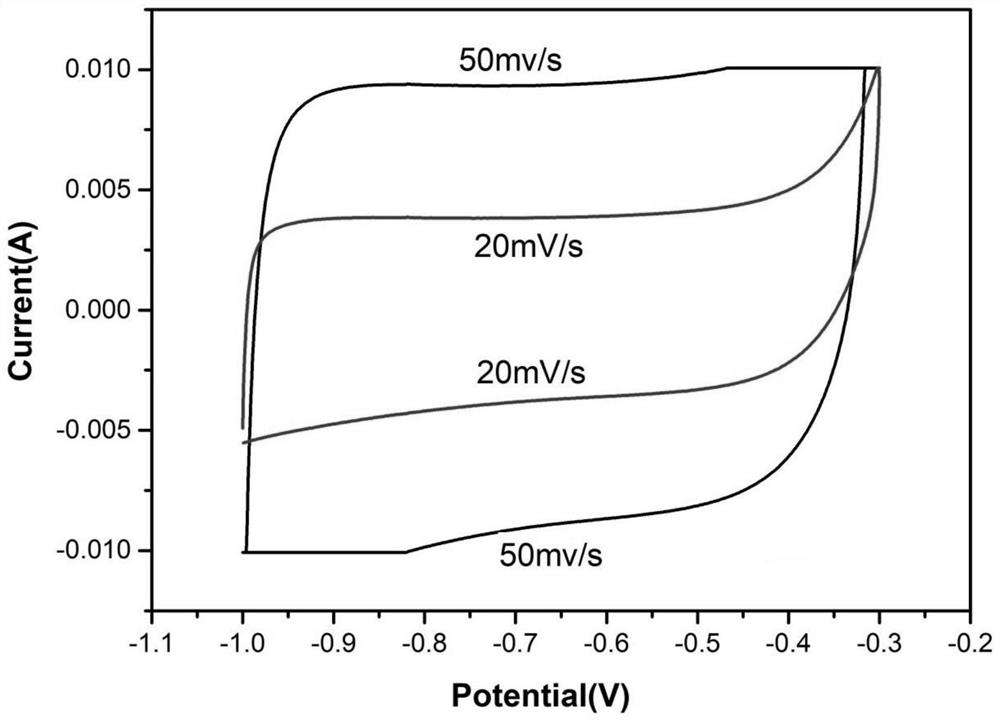

[0024] Embodiment 1: according to the following method with Ti 3 SiC 2 Preparation of two-dimensional material Ti as precursor 3 C 2 :

[0025] 1) Grind the titanium-silicon-carbon powder, sieve it to 200 mesh, place it in an alumina ark, spread it flat, raise the temperature to 550°C in a muffle furnace at a heating rate of 5°C / min, keep it warm for 3 hours, and then cool down with the furnace. As the furnace cools down, under the action of this oxidation temperature and holding time, the energy is high enough to make oxygen in the air enter the titanium-silicon-carbon lattice and interact with silicon atoms, weakening the Ti 3 SiC 2 The binding force of Ti-Si. The purity of titanium silicon carbon powder is >95%.

[0026] 2) Weigh 1 g of the powder obtained after oxidation, place it in 20 ml of HF solution with magnetic stirring, and heat in a water bath. The temperature of the water bath is 60° C., the time is 48 hours, and the concentration of hydrofluoric acid is 4...

Embodiment 2

[0030] Embodiment 2: according to the following method with Ti 3 SiC 2 Preparation of two-dimensional material Ti as precursor 3 C 2 :

[0031] 1) Grind the titanium silicon carbon powder, sieve 400 mesh, place it in an alumina ark, spread it flat, raise the temperature to 500°C in a muffle furnace at a heating rate of 8°C / min, keep it for 5 hours, and cool down with the furnace. The purity of titanium silicon carbon powder is >95%.

[0032] 2) Weigh 1 g of the powder obtained after oxidation, place it in 20 ml of HF solution with magnetic stirring, and heat in a water bath. The temperature of the water bath is 50°C, the time is 56 hours, the concentration of hydrofluoric acid is 35wt%, and it can float slightly down to 30wt%.

[0033] 3) Wash the mixed solution heated in a water bath with deionized water, centrifuge at 2500rpm, pour the upper layer solution until the pH value of the upper layer solution reaches 5-7, preferably 6, and continue to pour the deionized water ...

Embodiment 3

[0036] Embodiment 3: according to the following method with Ti 3 SiC 2 Preparation of two-dimensional material Ti as precursor 3 C 2 :

[0037] 1) Grind the titanium silicon carbon powder, sieve 300 mesh, place it in an alumina ark, spread it flat, raise the temperature to 580°C in a muffle furnace at a heating rate of 6°C / min, keep it for 2 hours, and cool down with the furnace. The purity of titanium silicon carbon powder is >95%.

[0038] 2) Weigh 1 g of the powder obtained after oxidation, place it in 20 ml of HF solution with magnetic stirring, and heat in a water bath. The temperature of the water bath is 80°C, the time is 72 hours, the concentration of hydrofluoric acid is 45wt%, and it can float slightly to 49wt%.

[0039] 3) Wash the mixed solution heated in a water bath with deionized water, centrifuge at 5000rpm, pour the upper layer solution until the pH value of the upper layer solution reaches 5-7, preferably 6, continue to pour the deionized water into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com