Synthesis method, product and application of C3N4 quantum dot room-temperature phosphorescent material

A room temperature phosphorescence, C3N4 technology, applied in the field of materials, can solve the problems of limitation, cytotoxicity, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

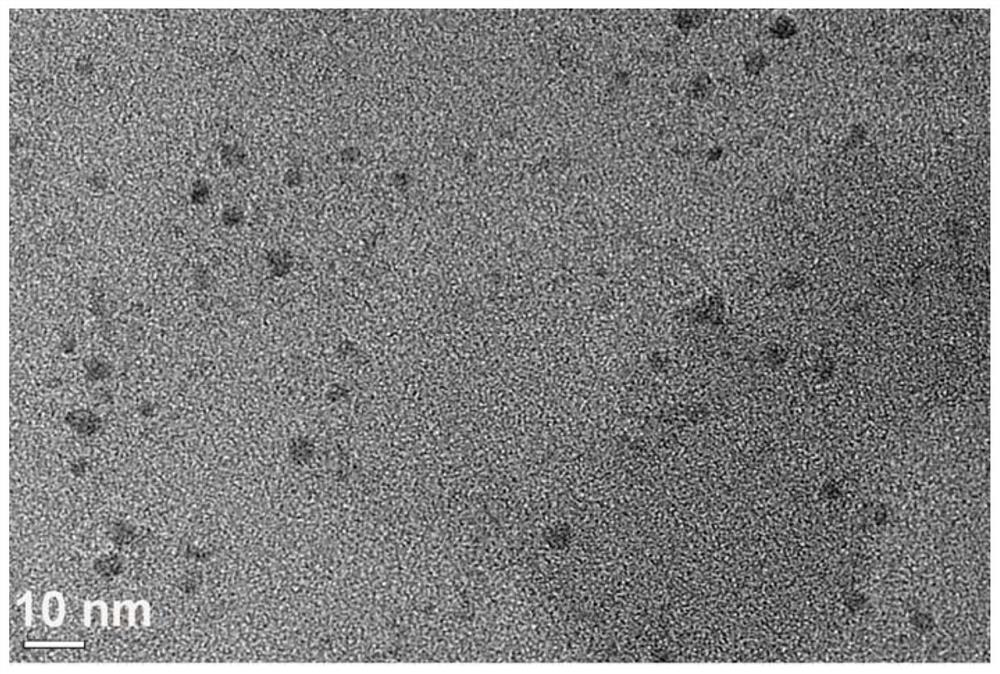

Image

Examples

Embodiment 1

[0027] With urea as reactant C 3 N 4 The synthesis of quantum dot room temperature phosphorescent materials, the specific steps are as follows:

[0028] (1) After grinding 20g of urea into off-white flour, transfer it to a reactor made of quartz glass with a volume of 50mL;

[0029] (2) The liner is then loaded into a high-temperature and high-pressure reactor according to the regular process;

[0030] (3) Set the reaction temperature to 300°C, the pressure to 8Mpa, the time to 3h, and the stirrer speed to 500rpm;

[0031] (4) After the reaction is over, wait for the reactor program to return to normal temperature and pressure, take out the liner and scrape the yellow-brown crude product;

[0032] (5) Ultrasonic dispersion of the crude product in an aqueous solution, followed by suction filtration with a filter membrane with a pore size of 220 nm;

[0033] (6) wash with dilute hydrochloric acid and ethanol successively, neutralize the product and remove other organic by-pr...

Embodiment 2

[0036] With hydroxyurea as reactant C 3 N 4 The synthesis of quantum dot room temperature phosphorescent materials, the specific steps are as follows:

[0037] (1) Grinding 10g of hydroxyurea into an off-white flour and transferring it to a reactor made of quartz glass with a volume of 50mL;

[0038] (2) The liner is then loaded into a high-temperature and high-pressure reactor according to the regular process;

[0039] (3) Set the reaction temperature as 250°C, the pressure as 4Mpa, the time as 2h, and the stirring bar rotating speed as 800rpm;

[0040] (4) After the reaction is over, wait for the reactor program to return to normal temperature and pressure, take out the liner and scrape the brown crude product;

[0041] (5) Ultrasonic dispersion of the crude product in an aqueous solution, followed by suction filtration with a filter membrane with a pore size of 220 nm;

[0042] (6) wash with dilute hydrochloric acid and ethanol successively, neutralize the product and r...

Embodiment 3

[0045] The synthesis of C3N4 quantum dot room temperature phosphorescent material with biuret as reactant, the specific steps are as follows:

[0046] (1) After grinding 15g of biuret into off-white flour, transfer to a reactor made of quartz glass with a volume of 50mL;

[0047] (2) The liner is then loaded into a high-temperature and high-pressure reactor according to the regular process;

[0048] (3) Set the reaction temperature to 270°C, the pressure to 5Mpa, the time to 3h, and the stirring bar speed to 500rpm;

[0049] (4) After the reaction is over, wait for the reactor program to return to normal temperature and pressure, take out the liner and scrape the brown crude product;

[0050] (5) Ultrasonic dispersion of the crude product in an aqueous solution, followed by suction filtration with a filter membrane with a pore size of 220 nm;

[0051] (6) wash with dilute hydrochloric acid and ethanol successively, neutralize the product and remove other organic by-products;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com