High-adaptability anti-oxidation laser cladding device

A laser cladding and adaptable technology, applied in coating, metal material coating process, etc., can solve the problem of low efficiency of laser surface repair, achieve good anti-oxidation protection effect, strong flexibility and adaptability, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

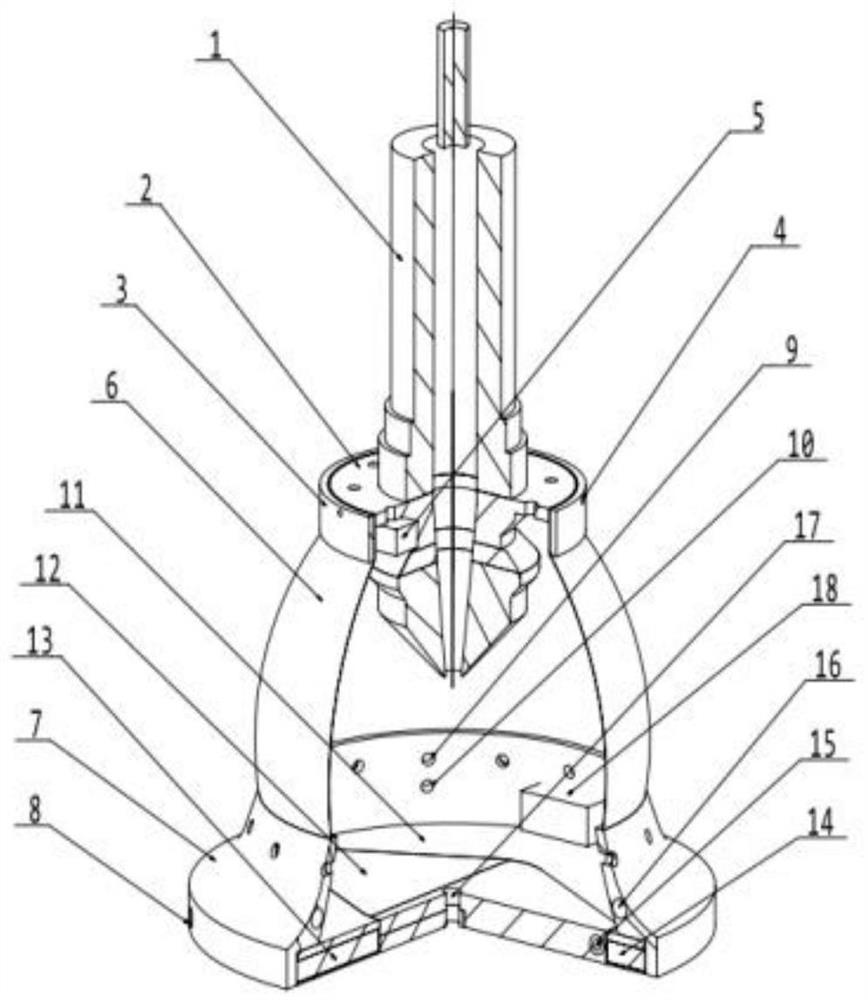

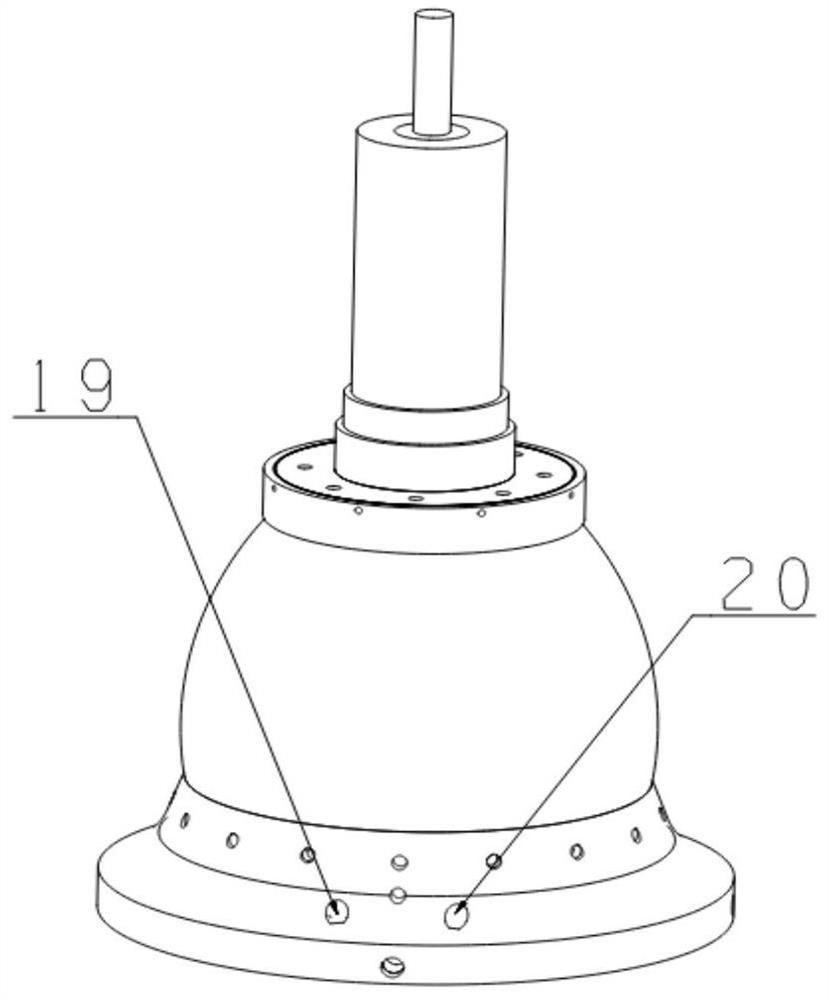

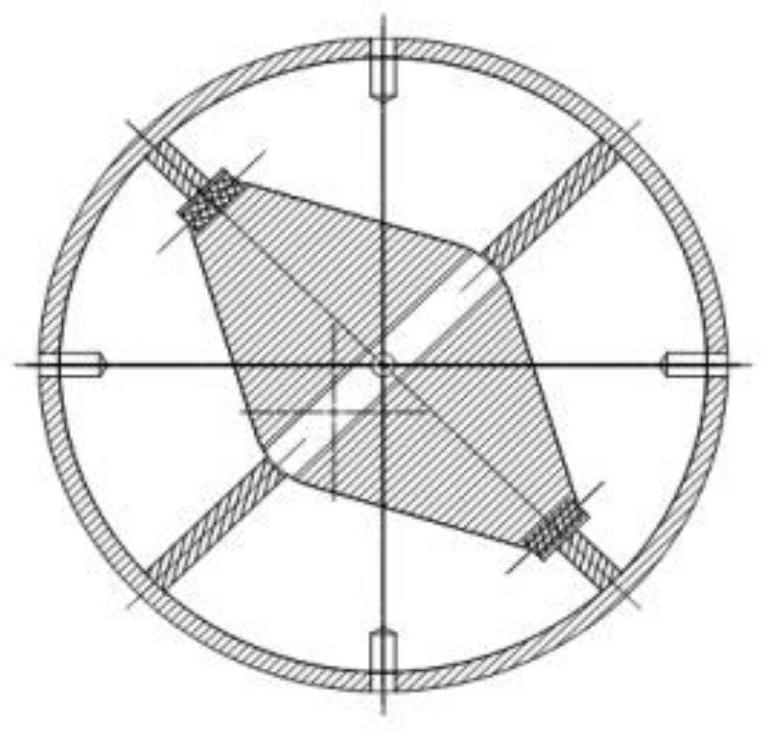

[0040] Example 1: The working process of using a highly adaptable anti-oxidation laser cladding device for laser additive non-ferrous metals is as follows: first connect the water-cooled pipeline, turn on the laser nozzle 1, connect the inert gas protection pipeline, and continuously feed high-purity argon Gas or nitrogen protective gas, the inert gas first enters from the first protective gas channel of the laser shower head 1, and then enters from the protective gas inlet 9 to form an air curtain together. By testing the oxygen content of the air pressure relief channel 10, it is judged whether the air is completely discharged. ; Second, wait for 1 to 2 minutes until the ambient atmosphere is stable; secondly, carry out local atmosphere laser additive work, adjust the powder feeding speed, test the cleaning function, and perform laser additive non-ferrous metals in an inert atmosphere according to the program instructions.

Embodiment 2

[0041] Example 2: The working process of using a highly adaptable anti-oxidation laser cladding device for laser additive non-ferrous metals is as follows: first, install the device, judge that the environment requires opening or dismantling the door 12, and will require partial repair or non-ferrous metal cladding Partially put it into the opening, and then rotate the protective cover according to the environmental requirements to adapt to the deformation, and finally carry out the sealing operation, and attach the magnetic parts to the surface of the workpiece to form a sealed space. If it cannot be completely fitted, the air curtain formed by the inert gas can be used to remove the air first. Then move to the surface of the workpiece, and then pass inert gas for 2 to 3 minutes to form a protective gas atmosphere, and then carry out specific repair or laser cladding work.

[0042] This highly adaptable anti-oxidation laser cladding device has the following advantages: (1) Clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com