Ultraviolet response peelable pressure-sensitive adhesive based on natural peach gum and preparation method thereof

An ultraviolet light and pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesives, can solve the problems of not meeting the development requirements of protecting the environment and carbon emissions, and achieve the effect of reducing the use of petrochemical-based raw materials, easy peeling, and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

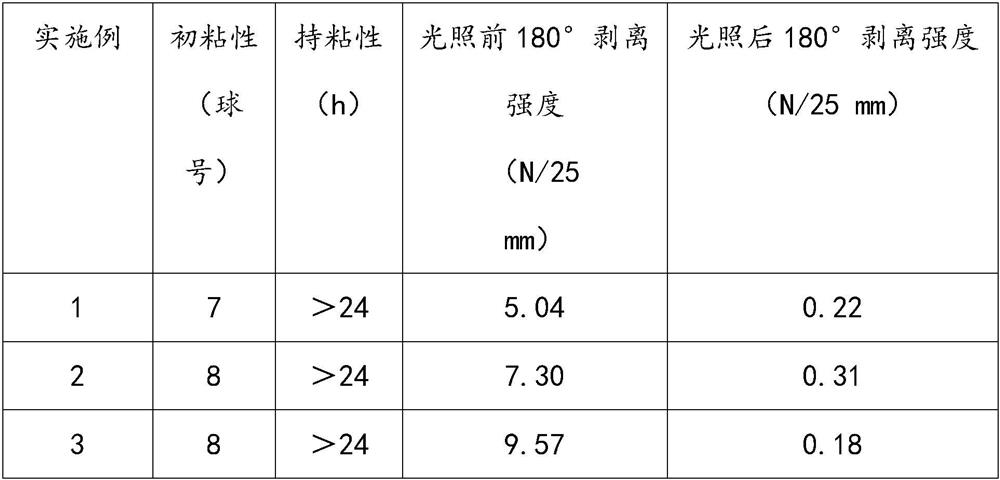

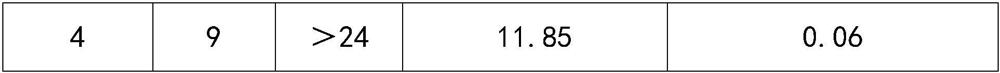

Examples

Embodiment 1

[0035] The first step, lithium chloride (2.91g) is dissolved in N, N-dimethylacetamide (26.15g), obtains the LiCl / DMAc solution of 10wt%, under the condition of stirring, adds 10.57g natural peach gum , the temperature was raised to 120°C, and the stirring was continued for 7 hours to obtain a viscous solution, which was filtered to remove impurities to obtain a peach gum solution.

[0036] In the second step, the concentration of 30% hydrogen peroxide aqueous solution (7.04g) was added to the peach gum solution obtained in the first step, mixed evenly, at room temperature, under the condition of stirring, the power used was 1500mW / cm 2 A UV point light source (wavelength 365nm) irradiated the solution for 25min to obtain the degraded peach gum solution.

[0037] In the third step, natural rosin (29.17g) is dissolved in N, N-dimethylacetamide (29.17g), mixed with the degraded peach gum solution obtained in the second step, and the peach gum-based adhesive is obtained after sti...

Embodiment 2

[0042] The first step, lithium chloride (2.33g) is dissolved in N,N-dimethylacetamide (20.92g), obtains the LiCl / DMAc solution of 10wt%, under the condition of stirring, adds 8.45g natural peach gum , the temperature was raised to 125°C, and the stirring was continued for 6 hours to obtain a viscous solution, which was filtered to remove impurities to obtain a peach gum solution.

[0043] In the second step, the concentration of 30% hydrogen peroxide aqueous solution (5.63g) was added to the peach gum solution obtained in the first step, mixed evenly, at room temperature, under the condition of stirring, the power used was 1500mW / cm 2 A UV point light source (wavelength 365nm) irradiated the solution for 25min to obtain the degraded peach gum solution.

[0044] In the third step, natural rosin (23.33g) is dissolved in N,N-dimethylacetamide (23.33g), mixed with the degraded peach gum solution obtained in the second step, and stirred to obtain the peach gum-based adhesive ;

...

Embodiment 3

[0049] The first step, lithium chloride (1.94g) is dissolved in N,N-dimethylacetamide (17.43g), obtains the LiCl / DMAc solution of 10wt%, under the condition of stirring, adds 7.04g natural peach gum , the temperature was raised to 130°C, and the stirring was continued for 6 hours to obtain a viscous solution, which was filtered to remove impurities to obtain a peach gum solution.

[0050] In the second step, the concentration of 30% hydrogen peroxide aqueous solution (4.69g) was added to the peach gum solution obtained in the first step, mixed evenly, at room temperature, under the condition of stirring, the power used was 1500mW / cm 2 A UV point light source (wavelength 365nm) irradiated the solution for 35min to obtain the degraded peach gum solution.

[0051] In the third step, natural rosin (19.44g) is dissolved in N,N-dimethylacetamide (19.44g), mixed with the degraded peach gum solution obtained in the second step, and stirred to obtain the peach gum-based adhesive ;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com