Braking system with double independent braking units and braking method

A technology of braking system and braking unit, applied in braking transmission, braking, transportation and packaging, etc., can solve problems such as poor braking reliability, and achieve the effect of compact layout, high adjustment accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

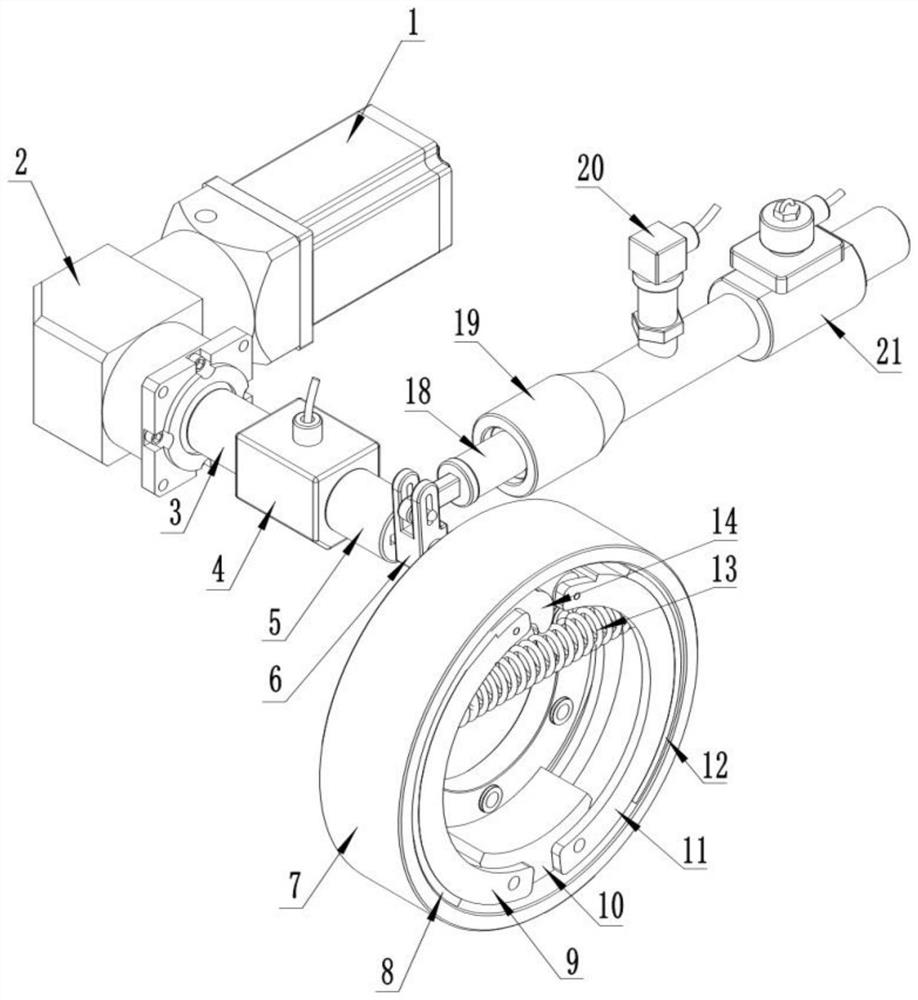

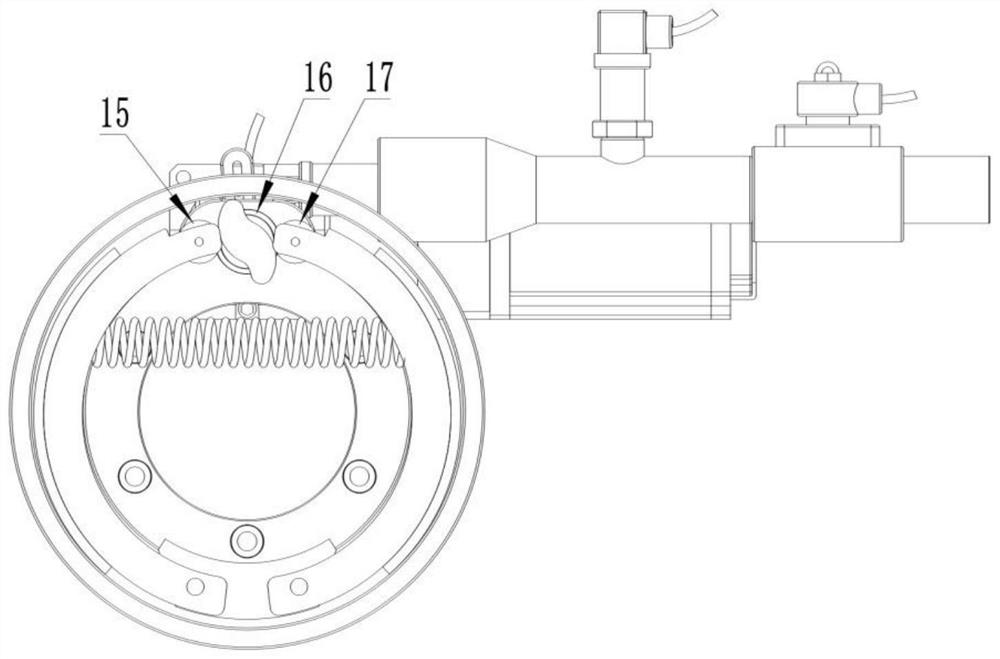

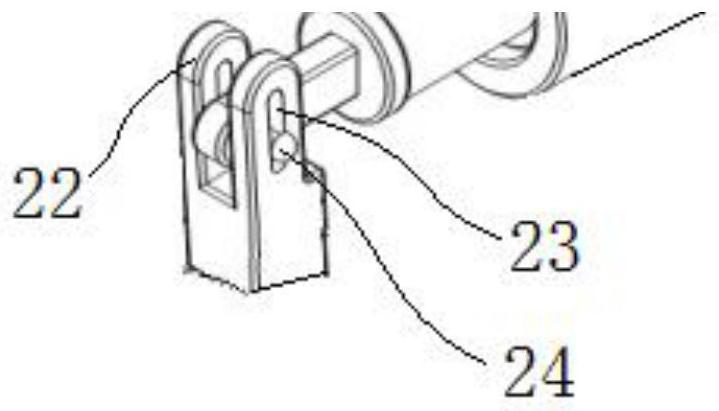

[0049] Such as Figure 1-Figure 2 As shown, the present embodiment provides a braking system 100 with dual independent braking units, including a drum brake, a hydraulic braking unit, an electromechanical braking unit and an electronic control unit, and the drum brake uses a cam 14 as an actuation device, the cam 14 is fixedly connected with a connecting rod 6, such as a key connection or a bearing connection; the hydraulic brake unit includes a master cylinder piston, a hydraulic sensor 20 and a wheel cylinder piston 18 connected to the master cylinder piston through a hydraulic pipeline 19, and the master cylinder The piston is used to connect with the brake pedal (the foot brake plate of the electric car), the wheel cylinder piston 18 is connected with the connecting rod 6, and the hydraulic brake unit can output the first torque to the connecting rod 6 driven by the brake pedal, so that The connecting rod 6 rotates; the hydraulic sensor 20 is arranged on the hydraulic pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com